It was 8:03 AM when the alarms blared. At a mid-sized automotive plant, a forklift operator spotted a frayed wire on Assembly Line, 3minutes before a potential fire. The near miss wasn’t luck. It was the result of a culture shift: the plant had started tracking SQDCM metrics—Safety, Quality, Delivery, Cost, and Morale—using a digital SQDCM board. Want to get more insights on how SQDCM enhances organisational safety goals?

Hope you understand the power of measuring SQDCM. But here’s what most leaders miss:

Morale isn’t a ‘soft’ metric—it’s the glue holding Safety, Quality, Delivery, and Cost together.

- Engaged teams drive better results – High morale fosters ownership, accountability, and proactive problem-solving.

- Low morale leads to high hidden costs – Disengagement fuels inefficiencies, errors, and increased turnover.

- A culture of recognition fuels performance – When employees see their impact, motivation soars, directly improving SQDCM outcomes.

- Psychological safety accelerates innovation – Teams confident in their roles contribute ideas that enhance productivity and quality.

To truly harness the power of SQDCM, it’s essential to measure the right metrics with the right approach. Let’s break down each element and explore how precise measurement drives continuous improvement.

SQDCM decoded: What gets measured, gets improved

In any manufacturing environment, SQDCM template serves as a foundation for continuous improvement. Tracking these five key metrics ensures operational efficiency, reduces risks, and enhances workforce engagement. Let’s explore how each element contributes to business success with the best SQDCM practices.

Safety: Preventing risks before they happen

A strong safety culture reduces workplace hazards and ensures compliance with industry standards. Measuring safety performance through incident tracking, near-miss reporting, and training completion rates helps identify trends and prevent accidents before they occur. Digital SQDCM boards make safety data instantly accessible, allowing teams to act swiftly on potential risks.

Quality issues directly impact customer satisfaction and production costs. Monitoring key metrics like first-pass yield, defect rates, and rework costs helps manufacturers maintain high product standards. By integrating real-time quality checks into daily operations, teams can detect and correct errors before they escalate, ensuring consistency in production.

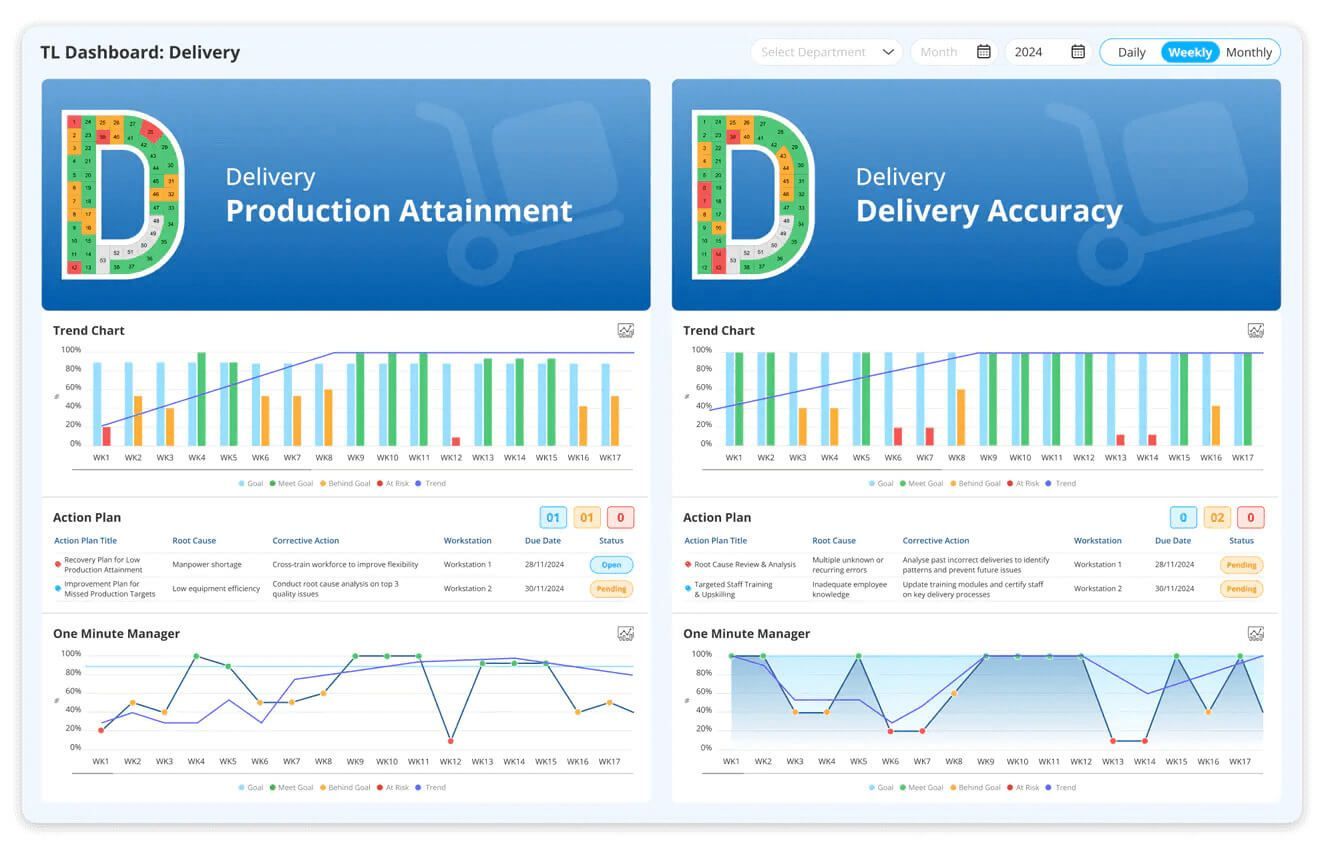

Delivery: Meeting deadlines, avoiding delays

Timely delivery is critical to maintaining supply chain efficiency. Tracking on-time delivery rates, backlog alerts, and production cycle times allows businesses to identify bottlenecks and improve scheduling. A data-driven approach to delivery management prevents costly delays and enhances customer trust.

Cost: Controlling expenses, improving profitability

Uncontrolled costs can erode profit margins. By measuring scrap rates, overtime hours, and energy consumption, manufacturers can pinpoint inefficiencies and reduce waste. Digital dashboards provide visibility into cost trends, enabling informed decision-making and long-term savings.

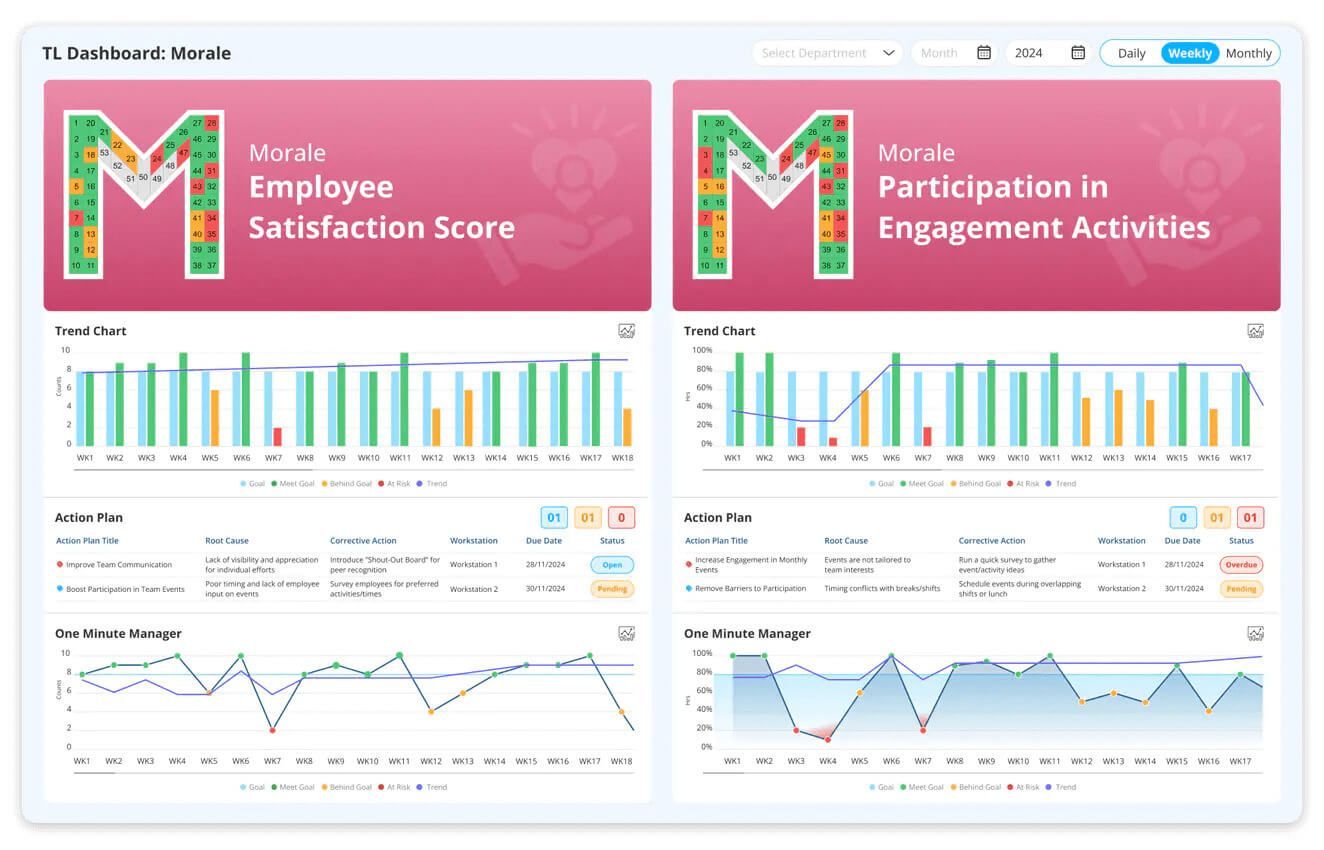

Morale: The key to productivity and retention

While often overlooked, employee morale has a direct impact on productivity, retention, and overall workplace performance. But how to measure morale? Metrics like pulse surveys, absenteeism rates, and turnover percentages offer insights into workforce engagement. Companies that actively monitor and improve morale benefit from higher productivity, reduced absenteeism, and lower employee turnover.

The right way to measure SQDCM in the Industry 4.0 era

The Fourth Industrial Revolution (Industry 4.0) has transformed manufacturing with smart tech like AI, IoT, and real-time data—but walk onto most factory floors, and you’ll find a stark reality: clipboards, spreadsheets, and paper checklists still rule. Teams drown in manual data entry, miss hidden risks, and struggle to connect Safety, Quality, Delivery, Cost, and Morale to real outcomes.

This gap isn’t just inefficient—it’s costly. While Industry 4.0 promises predictive maintenance and self-optimising production lines, many factories can’t even track downtime or morale in real-time. The truth? You don’t need robots or a full-tech overhaul to modernise. What you need is visibility.

Enter tools like the Digital SQDCM Board—a bridge between yesterday’s paper chaos and tomorrow’s smart factory. It’s not about replacing your team; it’s about empowering them with instant insights, automated reports, and action plans that turn raw data into daily wins.

From static tracking to smart monitoring

A digital SQDCM board can transform your business by offering intelligent performance management. Explore the advanced solutions and capabilities of modern tools like SQDCM boards of Data Point Balanced Scorecard software for enhancing your continuous improvement process:

- Real-time visualisation: Live dashboards update automatically, ensuring instant access to performance metrics.

- Automated reports: Data is collected, analysed, and structured without manual intervention, reducing errors.

- Action Plan Creation – Issues are flagged immediately, with predefined workflows assigning corrective actions.

- Integrated Scorecards – Align SQDCM metrics with business goals, enabling better decision-making.

- Predictive Analytics – Real-time, data-driven insights help forecast potential risks and improvement opportunities.

- Benchmarking & Trend Analysis – Compare performance across shifts, teams, or facilities to drive best practices.

- Cloud & Mobile Accessibility – Ensure leaders and teams can track SQDCM performance from anywhere.

- Integration with MES & ERP – Seamlessly connect SQDCM data with broader manufacturing and business systems for unified decision-making.

Beyond digital boards: The Future of SQDCM measurement

While Digital SQDCM Boards are the foundation of modern measurement, they are evolving with Industry 4.0, integrating advanced technologies. Let us look at the other advanced technologies that enhance visibility and responsiveness:

- IoT Sensors – Collect real-time machine and quality data to improve production consistency.

- AI & Machine Learning – Detect patterns and predict failures before they impact operations.

- Automated Workflows – Trigger corrective actions instantly based on deviations in key metrics.

- Voice-Activated & Chatbot Assistance – Enable operators and leaders to interact with SQDCM data hands-free for efficiency and accessibility.

Why measure SQDCM? Key takeaways and benefits you can’t miss

• SQDCM is human-centric:

Measuring Safety, Quality, Delivery, Cost, and Morale isn’t just about hitting targets—it’s about empowering people. When safety improves, morale rises. When morale rises, quality follows. It’s a cycle where every metric connects to your team’s well-being and performance.

Manual tracking and paper-based systems keep you stuck in the past. For enhancing your SQDCM strategies, adopting a digital board is the best option. It will bring clarity with real-time dashboards, predictive alerts, and automated reports that turn raw data into actionable insights.

• Industry 4.0 is here (No robots needed):

Modernising doesn’t require a factory overhaul. Simple, smart tools like digital boards bridge the gap between legacy systems and Industry 4.0’s promise of agility, precision, and foresight.

• Measurement drives momentum:

The way you measure shapes outcomes. Real-time visibility, benchmarking, and instant action plans turn SQDCM from a checklist into a culture of continuous improvement.

• Your next move:

If your teams are still drowning in spreadsheets, it’s time to upgrade. DataPoint’s Digital SQDCM Board isn’t just software—it’s your shortcut to safer floors, happier teams, and a future-ready factory.

Ready to move beyond static tracking? Discover how Data Point digital SQDCM board can drive real-time improvements