Data Point BSC and SQDCP board: LTS digital solutions for visibility and real time tracking

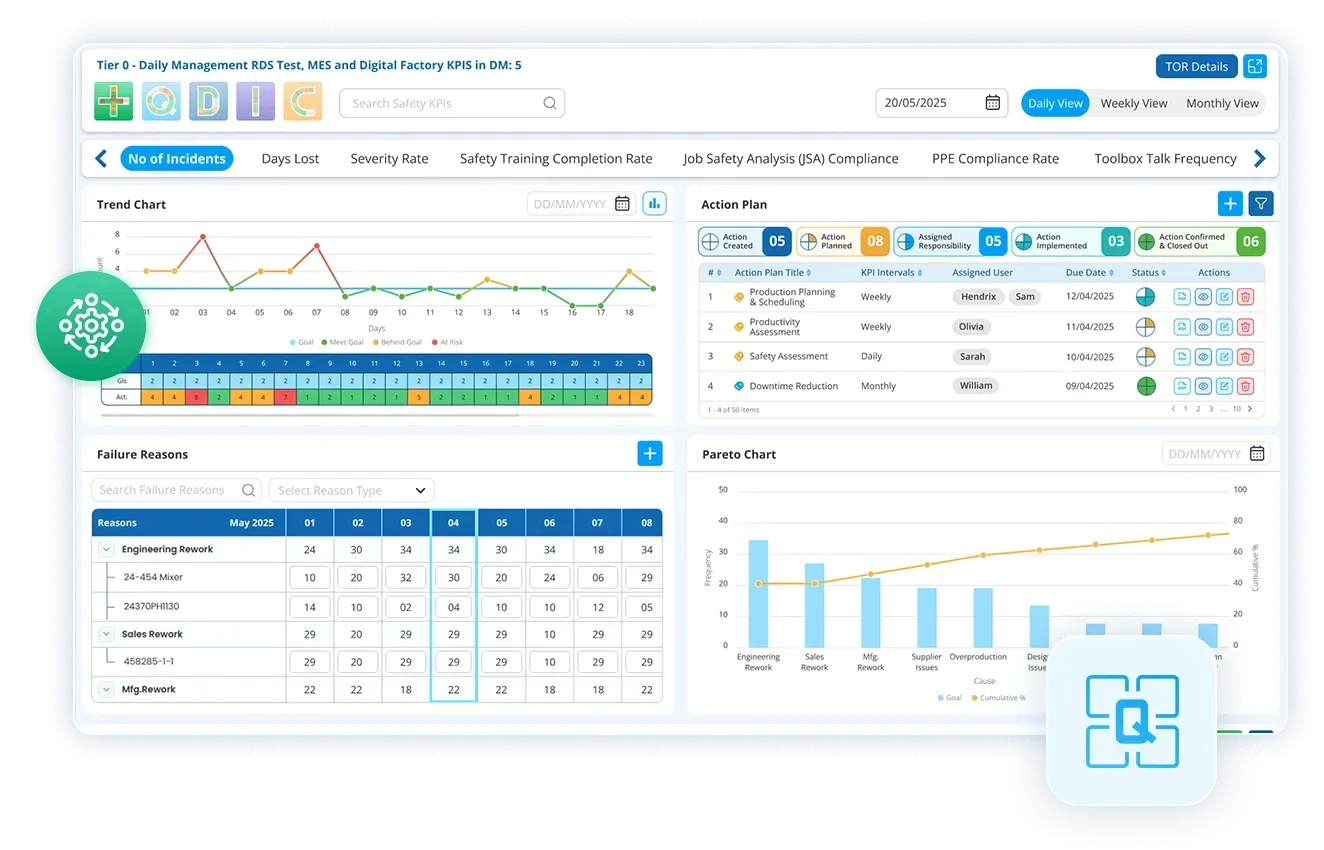

LTS Data Point balanced scorecard is an advanced performance or KPI management software by LTS for collection and tracking of specific, measurable values across the manufacturing process. Data Point transforms the shop floor into a real-time digital command centre. It acts as a smart factory balanced scorecard that tracks multiple dimensions of performance—not just output.

Data Point provides a variety of lean daily management tools for the unique needs of each industry. This includes huddle boards, gemba walks, visual management tools like SQDCP, SQDCL, FCIL etc. Among these, SQDCP dashboards are important and most common visual management tool used in lean manufacturing to monitor five key performance areas: Safety, quality, delivery, cost, and people. This framework can be customised for the tailored needs of specific industries like-SQDCEP framework add environmental metrics for green manufacturing, SQDCM- morale metrics for ethical manufacturing and so on.

Integrated with KPIs, Data Point manufacturing balanced scorecard provide actionable visibility that helps teams spot issues early, respond quickly, and drive continuous improvement. Their customisable layout ensures alignment between strategic goals and daily shop floor execution, tailored to each industrial needs. These dashboards help bridge the gap between top-level goals and ground-level execution.

Data Point + SQDCP framework = Full-spectrum visibility

Along with the SQDCP boards, Data Point systems provide the raw intelligence that powers visual management. Together, they:

- Turn complex operations into clear, actionable visuals

- Align teams around shared goals and performance metrics

- Drive faster problem-solving and continuous improvement

Key features

- Real-time data tracking and visualisation -displays live metrics digitally from machines, systems, and operators for instant decision-making.

- Automated KPI monitoring-tracks individual metrics like cycle time, scrap rate, tool usage, and operator actions with the help of sensors and software.

- Interactive dashboards-uses intuitive visuals to highlight performance status across categories.

- Highly customisable layouts-can be tailored to specific industry KPIs, needs, including additional metrics like inventory, morale or environment in SQDCP, SQDCM etc

- Integrated data sources-like ERP, MES, and IoT systems to create a unified view of operations.

- Historical trend analysis-tracks performance over time to support root cause analysis and long-term improvements.

- Aid mobile and cloud access-enables teams to view dashboards from anywhere, improving responsiveness and collaboration.

- Real-time reporting and analytics for instant insights into performance metrics, issue tracking, and decision support.

The impact of digital visibility in lean manufacturing industry

1. Improves transparency & real-time KPI visualisation

Everyone on the shop floor can instantly see how operations are performing. KPIs across critical categories are visualised in real time for better awareness and collaboration.

2. Supports daily stand-ups & corrective action planning

Facilitates quick team meetings to review live KPIs, plan countermeasures, and promote ongoing communication and accountability rather than guess work.

3. Enhances accountability & issue resolution

Clear metrics drive ownership and proactive problem-solving. Visual alerts help trigger follow-ups and corrective actions immediately.

4. Boosts efficiency, quality & issue detection

Early identification of abnormalities reduces downtime, scrap, and rework. Teams can act fast to address production or quality issues.

5. Optimise resource allocation and operational excellence

Real-time insights into machine usage and operator performance- support better scheduling, planning, and resource management to optimise operational excellence.

6. Supports predictive maintenance and safety metrics

Continuous monitoring of equipment data helps forecast failures ahead of time, minimising disruptions and reducing maintenance costs.

7. Improves decision-making, accuracy & responsiveness

Live dashboards eliminate guesswork and enable agile, data-driven decisions in response to real-time shop floor conditions.

8. Reduces waste, scrap, & over production

Visibility into defects and bottlenecks helps teams identify root causes and minimise unnecessary waste. Inventory and scheduling are optimised based on actual demand.

9. Strengthens strategic alignment and continuous improvement

SQDCP alignment keeps all teams focused on shared performance goals and drives continuous improvement. Executives can track trends and align resources accordingly.

10. Enhances compliance, traceability & audit-readiness

Full production traceability supports safety and legal compliance, reinforces data integrity, and ensures systems are ready for audits.

In today’s digitally driven smart factories, achieving full-spectrum visibility and operational excellence requires more than isolated tools. Smart manufacturing and end-to-end visibility have become strategic necessities. Success depends on an integrated ecosystem.

Data Point Balanced Scorecard empowers manufacturers with real-time performance tracking, visual management, and seamless integration across various systems and assets.

This powerful synergy doesn’t just enhance productivity—it drives a culture of continuous improvement, sharper decision-making, and sustainable growth across the entire manufacturing lifecycle.

Get Data Point to eliminate blind spots and improve your visibility