Closing the loop: How Gemba meetings strengthen Tier 1, 2, 3 meetings

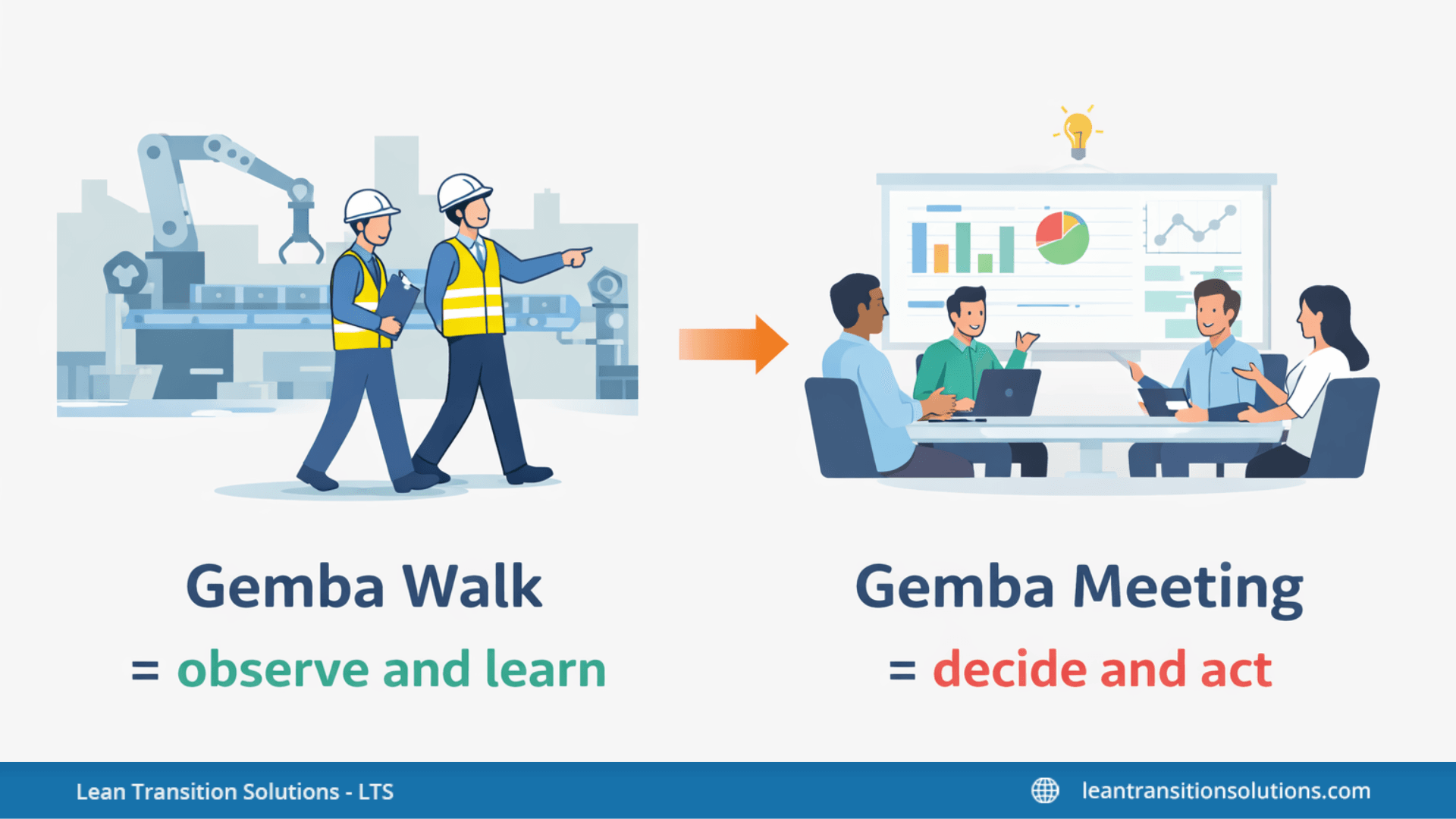

A Gemba meeting is typically the Tier 1 meeting in a tiered meeting system. It happens at the shop floor, often immediately after or during a Gemba walk, where teams review performance, identify abnormalities, and decide immediate actions.

When issues cannot be resolved at the Gemba meeting, they are escalated—not discussed again—into Tier 2 and Tier 3 meetings. Tier 2 focuses on cross-team coordination and root cause analysis, while Tier 3 addresses strategic or resource-intensive problems.

Here closing the loop means:

problems are seen at Gemba, acted on at Tier 1, escalated only when needed, and resolved at the right level—without repeating the same discussions.

Tier 1: Team huddle meetings (day-to-day actions)

Tier 1 is the frontline Gemba huddle meeting or SQDCP huddle or other metrics like SQDCM, SQDIP, SQDC etc. where teams:

- surface issues immediately

- track them on the Gemba huddle board

- assign actions that can be closed within a shift or 24 hours

Tier 2: Department manager meetings (escalation and coordination)

Tier 2 reviews consolidated issues that:

- need crossline coordination

- require resources (maintenance, engineering, QA)

- show repeated trends

Tier 2 should feel like problem-solving, not reporting. This is where the escalation board / tier board becomes the control system that prevents drift.

Tier 3: Executive leadership meetings (strategic alignment)

Tier 3 focuses on:

- recurring issues that require strategic decisions

- resource allocation

- cross-site standardisation

- policy or capability improvements

This is how a tiered meeting system (tier 1 tier 2 tier 3) closes the loop from shop floor reality to leadership decision-making. The Gemba meetings act as the base of all these.

How the Gemba tiers meetings connect the process flow

The strength of the tiered Gemba system is in the closed loop it creates:

- Tier 1: resolve within shift / 24 hours

- Tier 2: resolve within 48–72 hours

- Tier 3: strategic projects over weeks/months (with milestones)

This prevents “status meetings” and strengthens effective Gemba meetings.

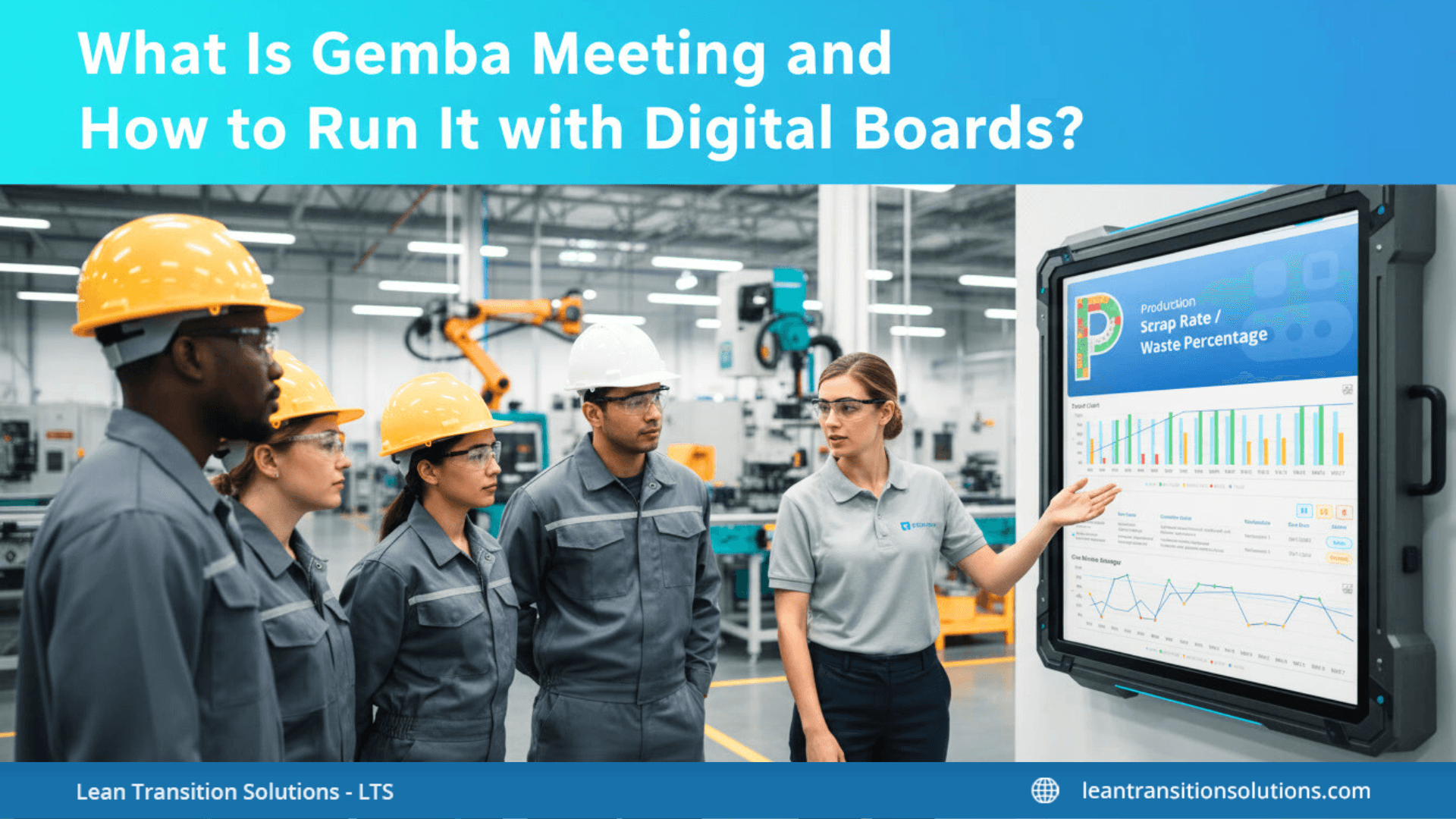

Digital Gemba boards for meetings: why they work (and what to show)

Traditional whiteboards can be inconsistent, hard to audit, and invisible across shifts or sites. Digital boards reduce these gaps by improving visibility, standardisation, and action tracking.

What to show on a digital Gemba board

Your Gemba board (or Gemba huddle board) should clearly show:

- SQDCP metrics or other shopfloor metrics like PQVC or PQDCM with targets and trends (SQDCP meeting / SQDCP huddle)

- Open actions with owner + due date + status

- Top abnormalities (today’s key constraints)

- Escalation path (Tier 1 → Tier 2 → Tier 3)

- Evidence where needed (photos/notes) to reduce debate

This keeps the daily Gemba meeting focused on decisions, not recollection.

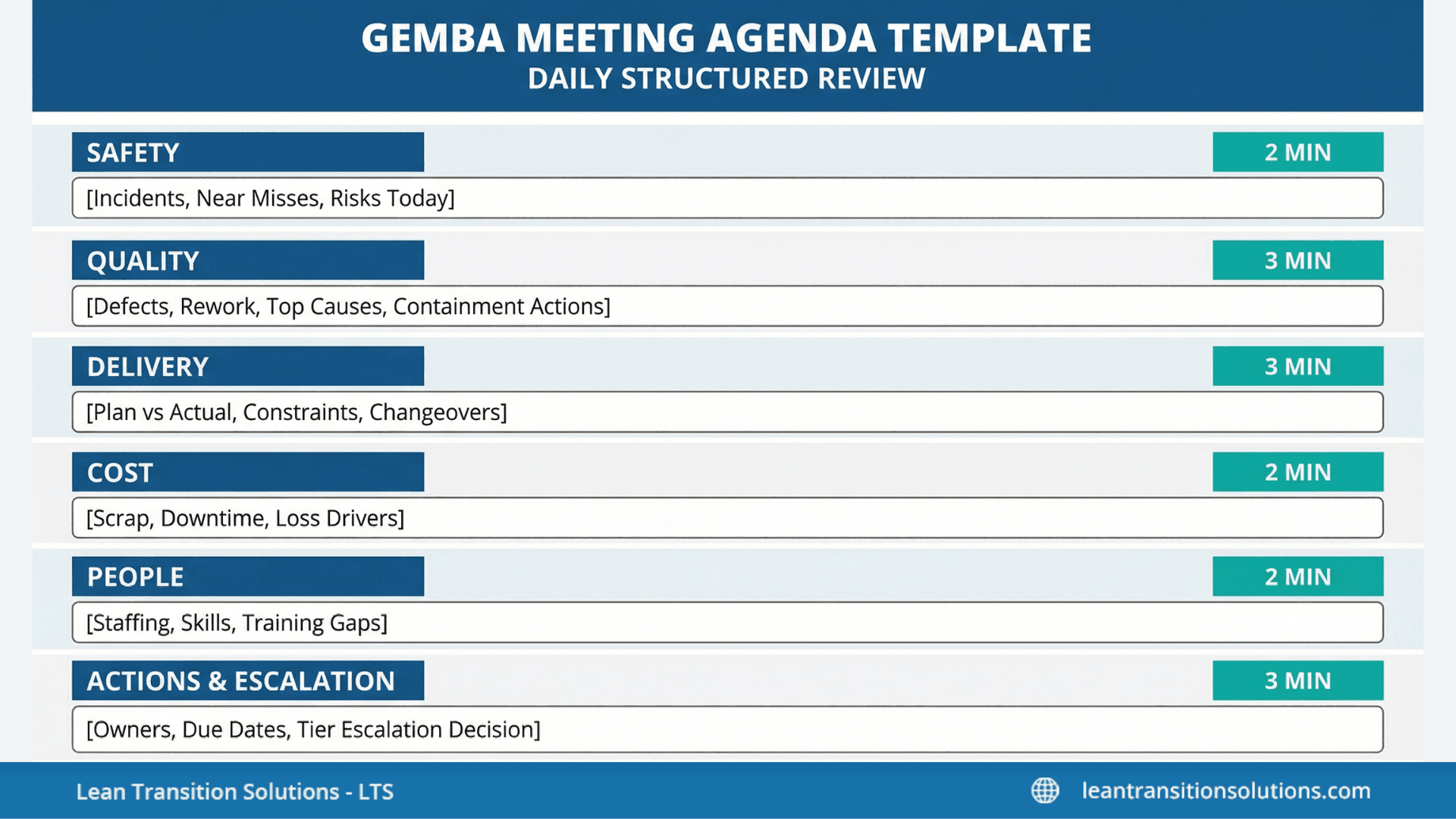

Best practices for smarter Gemba meetings

These are the habits that separate “daily updates” from effective Gemba meetings:

- Keep it short: time-box to 10–15 minutes

- Use the same Gemba meeting agenda every day

- Standardise the board layout across shifts/lines

- Review only abnormalities (don’t read every metric)

- Always close actions visibly (owner + due date + verify)

- Use the tiered meeting system (tier 1 tier 2 tier 3) to escalate fast

- Make the shop floor daily meeting predictables - ame place, same time, same format

Common mistakes that make Gemba meetings fail and fixes

1. Reading metrics without decisions

Fix: review only abnormal metrics and require actions.

2. No definition of “normal”

Fix: show targets, standards, and thresholds on the Gemba board.

3. No owner or due date

Fix: every issue must create an action with accountability.

4. No escalation rules

Fix: use an escalation board / tier board and clear Tier SLAs.

5. Meetings run too long

Fix: follow a standard Gemba meeting agenda and time-box each section.

6. Same issues repeat daily

Fix: add verification steps and confirm countermeasures worked.

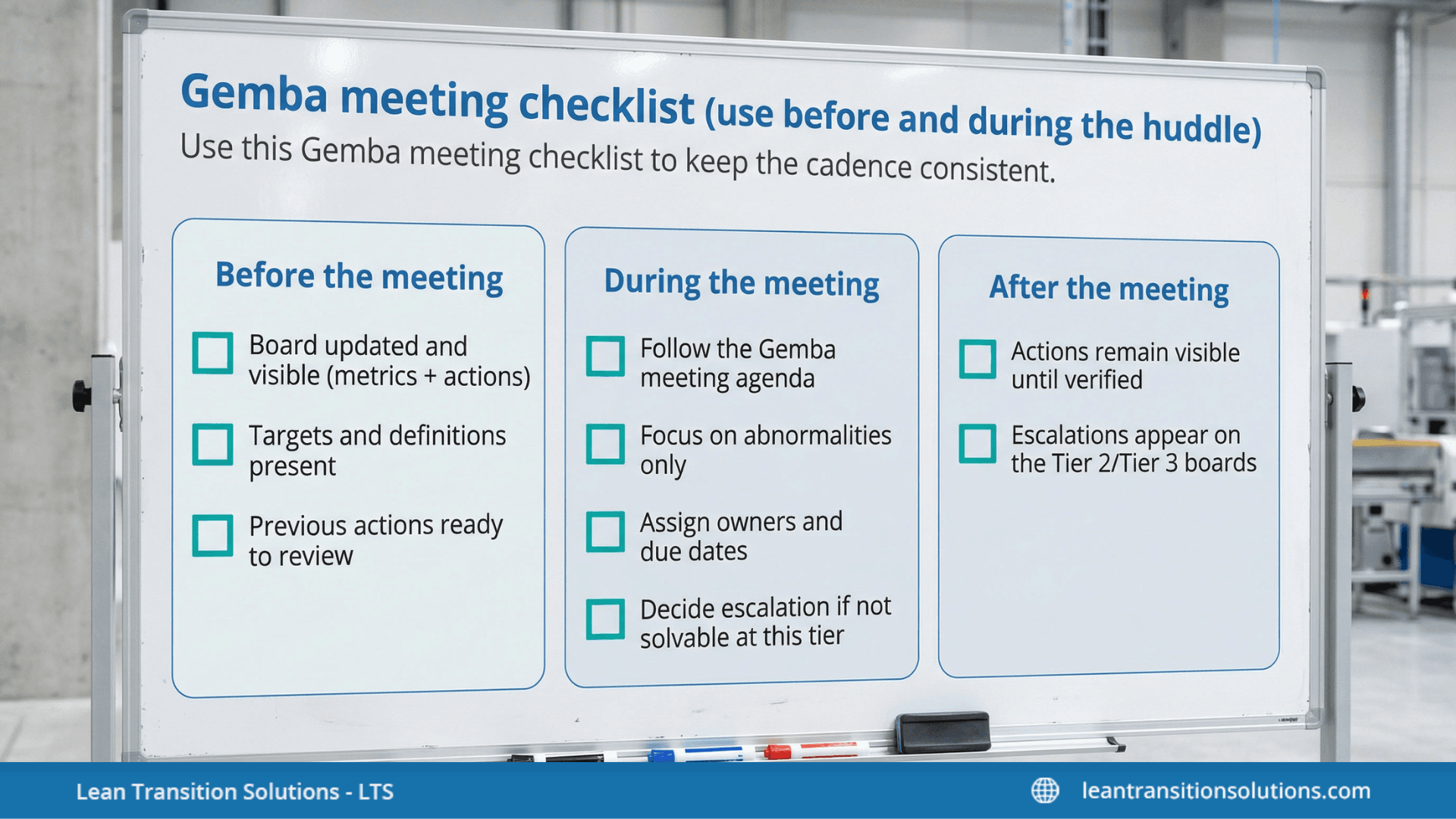

Gemba meeting checklist

Use this Gemba meeting checklist to keep the cadence consistent.

Before the meeting:

- Board updated and visible (metrics + actions)

- Targets and definitions present

- Previous actions ready to review

During the meeting:

- Follow the Gemba meeting agenda

- Focus on abnormalities only

- Assign owners and due dates

- Decide escalation if not solvable at this tier

After the meeting:

- Actions remain visible until verified

- Escalations appear on the Tier 2/Tier 3 boards

This checklist improves running a gamba meeting across teams without “style drift.” While this can be used in the Gemba meeting, it is recommended to carry out an efficient Gemba walk before. For that, use the Gemba walk checklist before you moving to Gemba meetings.

Data Point is a digital Gemba meeting and KPI board software designed to run a consistent daily Gemba meeting rhythm with SQDCP meeting / SQDCP huddle visibility and structured escalation through Tier 1, Tier 2, and Tier 3 meetings.

It’s typically used when teams need:

- standardised Gemba boards across shifts or sites

- real-time KPI visibility (not outdated updates)

- accountable action tracking with escalation

- consistent daily routines without manual rollups

In summary

A Gemba meeting works when it’s short, standardised, and action driven. Use a consistent Gemba meeting agenda, make “normal vs abnormal” visible on a Gemba board or Gemba huddle board, and close actions quickly through a tiered meeting system (tier 1 tier 2 tier 3). If you want effective Gemba meetings, focus on decisions, ownership, and verification, not reporting.