How to run effective Tier 1, Tier 2 and Tier 3 meetings with Data Point?

Last updated on : August 19, 2025

Imagine a relay race!

Each runner hands the baton to the next, trusting they’re in sync.

In a relay race, it’s not just speed that wins the game—it’s coordination. Each runner must be in sync, passing the baton at exactly the right moment, with total clarity and trust. If one runner hesitates, drops the baton, or isn’t prepared, the entire race can be lost—no matter how fast the individual runners are.

Tier meetings, the foundation of organisational success, are like a relay race—if not executed or coordinated well, the entire strategy can fails.

Along with that, what if the relay coach is silent on the sidelines—no feedback, no tactical changes.

Without real-time input, runners repeat the same mistakes. A smart coach step in after every lap — observes the competitors, reads the pace, adjust the strategy based on competition, and most importantly, boost the team’s morale. They don’t wait for the race to end. They optimise performance while the race is on.

Tier meetings in manufacturing act just like a coach in sports—offering guidance, strategy, and support at every stage.

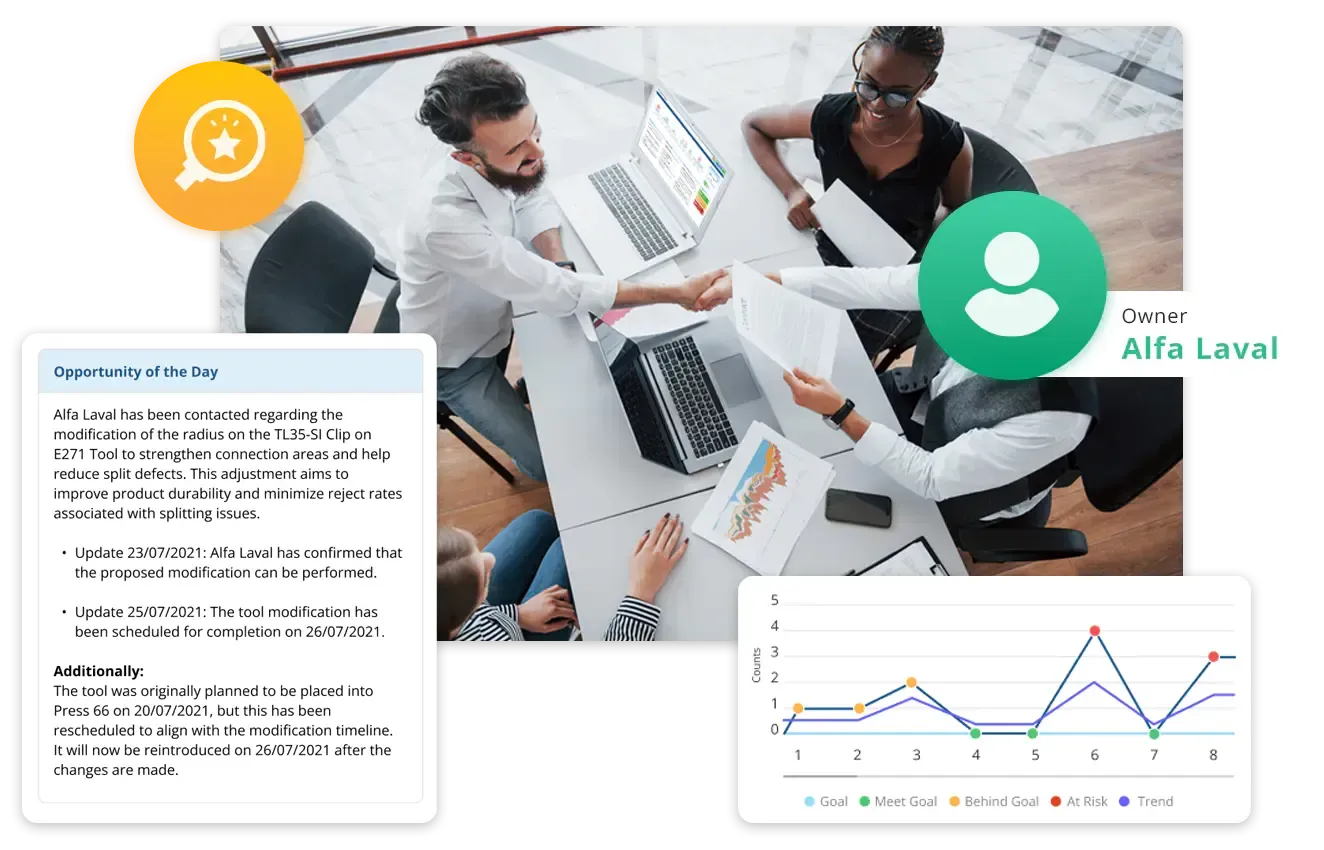

In this blog, we’ll explore how LTS Data Point-digital balanced scorecard can work better when combined and customised with different software and frameworks—giving each team member a clear view of their role across all tiers.