What is a Gemba Walk checklist?

The importance of Gemba Walk checklists: Why they matter for continuous improvement

Understanding what a Gemba walk is and its purpose is essential for anyone committed to building a culture of continuous process improvement. In lean manufacturing, a Gemba walk is more than just 'going to Gemba'; it is a purposeful visit to where work happens to engage with employees, spot deviations from standard procedures, and uncover improvement opportunities in real time. The checklist here is the key element of a Gemba process that uncover true insights.

A Gemba walk checklist ensures the walk is structured, allowing managers, team leaders, and executives to focus on critical elements like safety, quality, productivity, and employee engagement. It helps to make each visit meaningful rather than a simple site walkthrough.

➤ Gemba walks checklists are essential to strengthen the Gemba walk

One key goal of a Gemba walk is deepening the understanding of how work really happens. Asking the questions directly from the checklist, rather than relying on second-hand reports, uncovers hidden challenges and barriers. Using structured Gemba walk checklist questions examples such as "What obstacles slow you down?" or "Where do handovers cause delays?" helps leaders and team members engage meaningfully and understand what is ongoing easily.

➤ Leaders and team members can identify the waste in process and deviations from standard procedures

A well-structured checklist allows leaders to spot waste and deviations from standard procedures during the walk. Whether it's wasted time, excess movement, or unnecessary materials, a Gemba checklist ensures nothing is overlooked.

➤ Quality, safety, and compliance will improve through structured observation

Using a safety Gemba walk checklist ensures that safety hazards, risk areas, and compliance breaches are not overlooked. At the same time, checking for quality standards in real time supports faster corrective actions.

➤ Capture employee suggestions and ensure inclusiveness that fuel improvement opportunities

In lean Gemba methodology, the voice of employees is critical, and checklist serves as a tool for capturing employee insights. By asking open-ended questions such as “What improvement opportunities do you see today?” or “Is there anything preventing you from doing your best work?” leaders engage employees in continuous improvement and empower them to contribute their valuable suggestions.

➤ Bridges the gap between performance data and workplace reality with Gemba walks

While performance data and Key performance Indicators (KPIs) are essential for understanding trends and making data-driven decisions, Gemba walk checklists provide the context behind the numbers. The checklist helps connect performance metrics with real-world observations, allowing leaders to understand the root causes of performance gaps and make more informed decisions.

➤ Enable continuous improvement through regular Gemba days

Having a consistent checklist for regular Gemba walks - whether daily or on scheduled Gemba days — ensures that teams can address small issues before they grow into larger problems. This proactive approach aligns with the core principle of continuous improvement, enabling steady progress and fewer disruptions.

Gemba Walk checklist: Key elements

An effective Gemba walk checklist does more than ask questions — it provides a structured framework that guides leaders, supervisors, and team members in observing, analysing, and improving workplace operations with clarity and intent. It boosts your Gemba walk efficiency and communicate the real purpose. Below are the core elements that every impactful checklist should contain.

1. Checklist foundation and context

- General details

Basic information including date, time, location, department, responsible person, and area under observation. Enables traceability and supports performance comparisons across time and teams.

- Defined purpose or focus area

Specifies whether the walk targets safety, quality, productivity, process efficiency, or workforce engagement. Ensures observations are aligned with specific improvement goals.

- Linked KPIs

References to relevant key performance indicators, connecting checklist observations to measured outcomes. Reinforces alignment between real-time conditions and strategic targets.

2. Core observation categories

- Standards and compliance

Verification of adherence to Standard Operating Procedures (SOPs), visual standards, and standardised work instructions. Identifies variations that affect quality, safety, or efficiency.

- Workplace organisation (5S principles)

Assessment of cleanliness, tool arrangement, visual labelling, and space utilisation based on 5S or similar frameworks. Ensures efficient, safe, and orderly environments.

Benefits of using a Gemba Walk checklist

A Gemba walk checklist is more than just a list of things to observe, it’s a structured tool that ensures consistency, focus, and follow-through during workplace observation. Without a checklist, Gemba walks can become vague, inconsistent, or even counterproductive. Here's a breakdown of the key benefits:

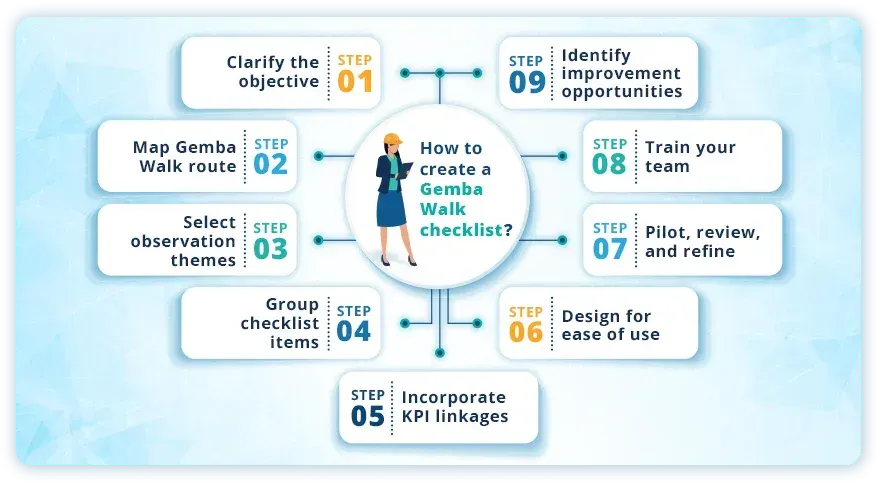

Creating a Gemba Walk checklist (Steps to create a custom checklist for your facility)

While general templates offer a starting point, the real value lies in building a Gemba walk checklist customised to your facility’s environment, goals, and culture. Whether you’re in manufacturing, service, logistics, or an aerospace shopfloor setting, your checklist should align with the purpose of Gemba walk, support daily observation practices, and strengthen continuous improvement.

Clarify the objective of the Gemba walk

Every checklist should begin with a clear purpose. Are you focusing on safety, quality, productivity, employee engagement, or a specific improvement project? Defining the goal will determine the types of observations and areas of focus. For example:

- A safety Gemba walk might prioritise hazard identification and compliance indicators.

- A Gemba walk for lean manufacturing might focus on flow, waste, and standards adherence.

Map Gemba Walk route and processes

Use facility layouts or process maps to identify the key zones, areas or operations to observe such as high-risk areas, bottlenecks, or customer-impacting operations. For manufacturing, this may include the shopfloor, workstations, material storage, and inspection points. In service sectors, it may focus on communication hubs or digital workflows. Mark and specify this in your checklist.

Select observation themes and checklist elements

Choose what themes your checklist should consistently cover. Common ones include:

- Standard operating procedures and deviations

- Waste in process and workflow delays

- Communication gaps

- Equipment reliability

- Team collaboration and leadership presence

- Employee suggestions and participation

- Visual management tools like Gemba boards

Use categories to group checklist items

Organise your checklist into grouped sections such as:

- Safety

- Quality

- People and culture

- Equipment and materials

- Visual controls

- Escalation or problem-handling

This structure helps maintain clarity during the walk and allows for quick comparisons over time.

Incorporate KPI linkages where applicable

While Gemba walks are observational, integrating Key Performance Indicators (KPIs) ensures alignment with business goals. For example, tie observed downtime to OEE monitoring or track how quality issues relate to customer complaints.

This ensures your Gemba walk isn't just a visual scan but a complementary process to data-driven management.

Design for ease of use and flexibility

A checklist should guide observation, not restrict it. Use a mix of yes/no options, open comments, and space for capturing anomalies. Digital Gemba software can help you adapt checklist formats by shift, department, or facility - supporting faster input and data review.

Pilot, review, and refine

Test the checklist with supervisors or team leads during actual walks. Collect feedback:

- Are key issues being uncovered?

- Are some sections irrelevant?

- Are there duplicate or unclear items?

Use this input to refine your checklist regularly - especially as processes evolve or new safety regulations are introduced

Train your team on intent and execution

Without clear understanding, a checklist becomes just another form to tick off. Train team leaders, managers, and frontline employees on Gemba walk meaning, how to conduct it collaboratively, and how to use the checklist as a tool for learning, not policing.

Identify improvement opportunities

Your checklist isn’t just for spotting process issues — it should evolve as your facility, goals, and challenges do. After each walk, reflect on two areas: what can be improved on the shopfloor, and how the checklist itself can be refined for future use.

- What recurring issues were observed today?

- Did any checklist sections feel outdated or unclear?

- Were there missed opportunities to capture data on new initiatives?

- How could this checklist better support continuous improvement?

Checklist improvement insights:

- Add items based on team feedback or recurring observations.

- Retire irrelevant or repetitive points.

- Expand scope to support ESG, digitisation, or compliance audits.

- Integrate follow-up fields or improvement status tracking.

Operational improvement capture:

- Identify action points tied to flow, safety, quality, or training.

- Use the checklist data to update SOPs or Kaizen boards.

- Feed into KPI dashboards or short interval management reviews

Digital vs paper Gemba Walk checklists

Choosing the right format for your Gemba walk checklist can significantly impact the effectiveness and consistency of your observation process. While traditional paper-based checklists are still common, digital solutions offer clear advantages that are best fit for your organisation.

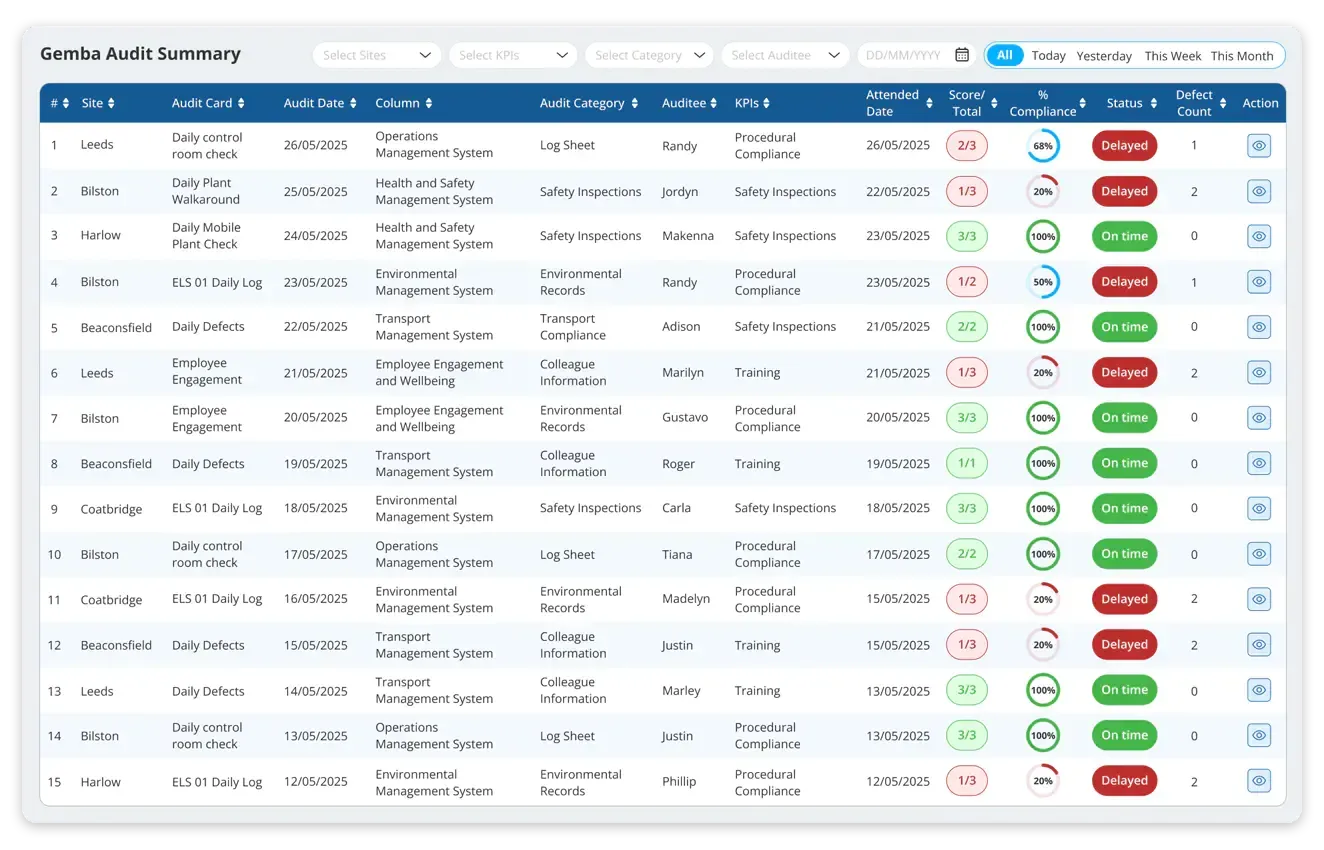

The rise of digital Gemba: Enabling smart manufacturing through real-time insight

Digital Gemba walk- a tech-enabled evolution of traditional on-site observation is gaining momentum as it serves the necessities across the modern shop floor. Unlike manual methods, it uses Gemba dashboards, digital checklists, and cloud-based tools to record findings instantly and trigger follow-up actions. In the age of Industry 4.0 and smart manufacturing, Gemba board approach enhances visibility, reduces delays, and supports faster, more informed decision-making.

Have a look on how it is different from the traditional paper based Gemba walk or checklist.

A comparison of traditional Gemba walk checklist and Digital Gemba walk checklist

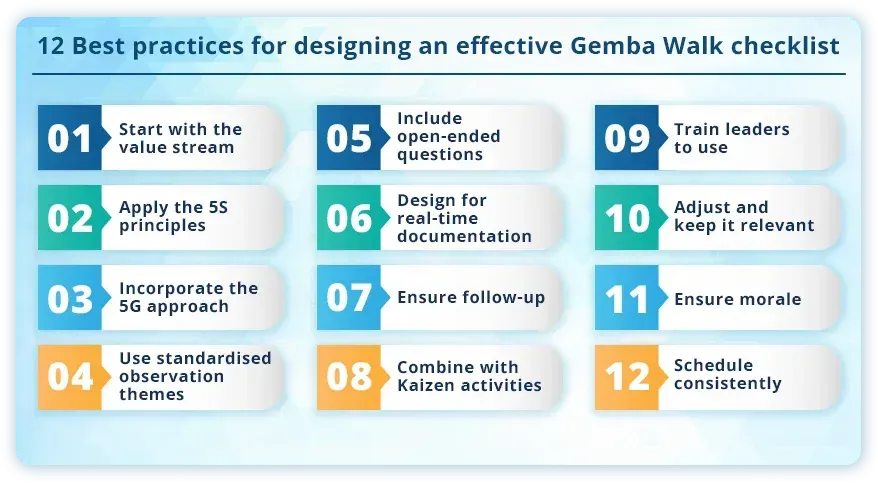

12 Best practices for designing an effective Gemba Walk checklist for continuous improvement

Effective Gemba walks follow a structured, respectful approach that combines observation, questioning, and action. Whether you're using a manual or digital Gemba process, these best Gemba checklist help to ensure consistent value. The following best practices bring together traditional lean thinking with digital-age execution.

1. Start with the value stream

When designing a checklist, anchor it in how value flows through each step of the process. Include prompts to observe bottlenecks, handoffs, rework, and waiting times, linking checklist items to key customer outcomes.

2. Apply the 5S principles of Gemba into checklist

Ensure the workplace supports efficiency and safety by implementing 5S principles in Gemba checklist:

- Sort (remove unnecessary items)

- Set in order (organise what remains)

- Shine (clean and inspect regularly)

- Standardise (ensure consistency)

- Sustain (maintain and review standards)

5S provides a visual and functional baseline for spotting abnormalities and identifying areas for improvement, especially while during your Gemba process.

3. Incorporate the 5G approach

The 5G framework of Gemba reinforces how leaders should approach Gemba. Design checklist items that prompt observation of:

- Genba – go to the actual place where work happens

Gemba Walk checklist example: Key focus areas for the Manufacturing industry

❓❗Did you know? Toyota, a global leader in manufacturing excellence, uses separate Gemba checklists depending on whether the walk is focused on safety, quality, or productivity. Each checklist is tailored to its purpose, ensuring observations are aligned with real improvement goals.

Gemba walk checklist for manufacturing sector: Driving shop floor improvement where it matters most

In the manufacturing sector, Gemba walk checklist provides a structured approach to capturing observations directly from the shop floor. With complex machinery, multiple process layers, and people-driven operations, using a tailored checklist ensures consistency in what is observed, documented, and improved. It transforms routine walk-throughs into action-oriented audits aligned with operational goals.

To maximise effectiveness, a manufacturing-specific checklist should be organised by focus areas that matter most to daily operations and continuous improvement efforts:

➤ Process integrity and flow

Machines are central to manufacturing. Watch for unusual noises, breakdown signs, or poor setups. Gemba walk checklist here should cover how equipment is maintained and whether operators perform basic checks.

A Gemba walk checklist to focusing on process integrity and flow must concentrate on how material, information, and tasks move across each workstation.

What to do:

Observe product movement, part handoffs, and process transitions. Look for signs of imbalance, such as waiting time, bottlenecks, and excess motion.

Example Gemba walk checklist questions:

- Where does the process slow down the most during peak hours?

- Is there any work being redone or repeated here?

➤ Equipment reliability and maintenance

What to do:

Check for PM tags, visual status indicators, and adherence to Total Productive Maintenance (TPM). Observe whether issues are logged and escalated.

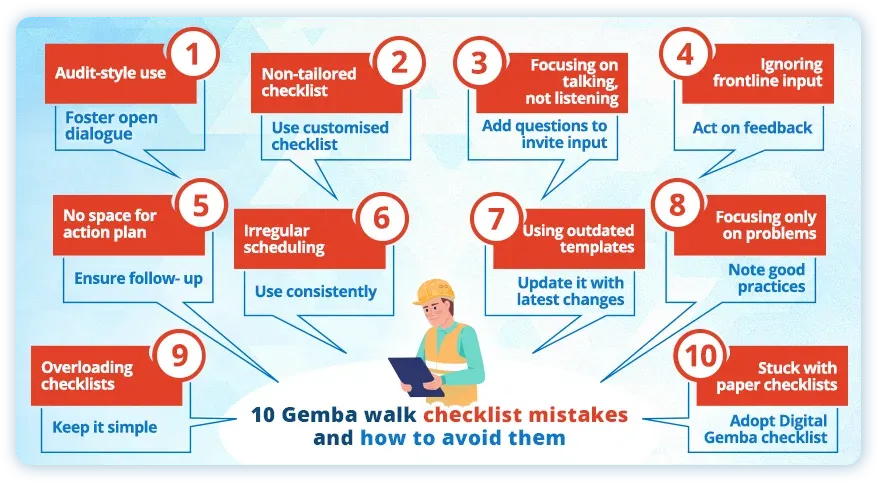

Common Gemba walk and Gemba checklist mistakes and how to avoid them

Even well-intended Gemba processes can lose impact when the checklist behind them is misused or neglected. These mistakes often lead to missed insights, poor follow-up, and disengaged teams. Recognising and correcting them ensures the Gemba process stays meaningful, consistent, and improvement focused.

- Treating the checklist like an audit form

Gemba walks are not formal inspections. When leaders treat them like audit forms, it discourages openness and hides real issues. Instead, use it as a guide to foster open dialogue and uncover real-time shop floor insights.

- Walking in without a tailored checklist

Entering the floor without a focused checklist or theme leads to random, unfocused observations. Each checklist should be customised to the process, area, or goal to yield actionable insights.

- Focusing the checklist around talking, not listening

Checklists should include prompts that encourage input, not just things to observe. Include questions like “Any suggestions to make this task easier?”

- Ignoring frontline input

Operators often highlight issues that aren’t visible on dashboards. If checklist feedback fields are filled but not reviewed or acted upon trust breaks down, and future walks lose value.

- No connection between checklist and follow-up

Observing problems without driving resolution creates frustration. A Gemba checklist should always lead to action plans, owner assignments, and visible follow-up. Ensure there is a space in your checklist for action plans.

- Inconsistent scheduling

Skipping days or using the checklist irregularly causes lost insights. Build a routine (daily, weekly, shift-based) and set reminders or alerts via digital tools to ensure consistency.

Use Data Point Balanced Scorecard as your digital Gemba Walk tool

To fully realise the value of Gemba Walks in the era of Industry 4.0, traditional clipboards and manual notes are no longer enough. Data Point Balanced Scorecard Software transforms how organisations approach Gemba by digitising every layer of the walk — from checklists and KPI dashboards to action plans and real-time performance tracking.

This powerful platform supports:

- Virtual Gemba Walks – Ideal for multi-site and remote teams, enabling leadership visibility without physical presence.

- Define Objectives: Clearly outline goals and identify key processes for improvement.

- Gemba dashboards & Digital huddle boards – Visualise live metrics, improvement projects, and open actions directly on the shop floor.

- Integrated checklists & Question flows – Customisable templates guide consistent observations across shifts and departments.

- Short interval management (SIM) boards – Capture performance at frequent intervals for immediate response and problem-solving.

- Performance & KPI analysis – Access historical and real-time data, compare against targets, and link observations to organisational strategy.

- Root cause tracking & Action plans – Assign actions, track deadlines, and escalate unresolved issues directly from your walk.