7 Common mistakes in A3 problem solving and how to solve it

The A3 problem solving is designed to break down problems, analyse root causes, and guide continuous improvement. But even the best tools can fall short if misused.

Are you unknowingly sabotaging your A3 efforts? Let's look at seven common mistakes in A3 problem solving, and more importantly - how to avoid them.

1. Treating A3 as a mere template

What A3 really is:

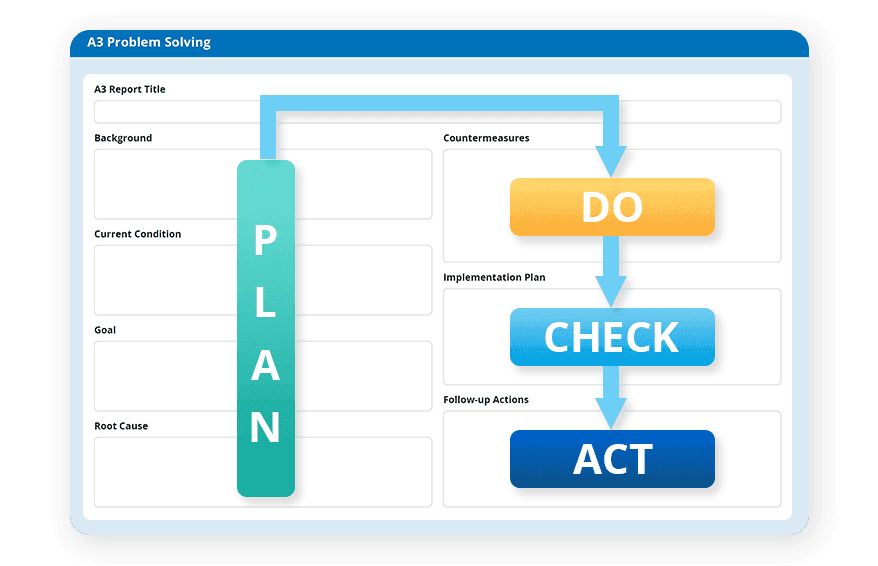

At its core, the A3 format promotes structured thinking, visual management, and team collaboration. It’s not just a form; it’s a Lean communication tool that guides users through the PDCA (Plan–Do–Check–Act) cycle on one page. Unfortunately, many treat it like a paperwork exercise just to write down the problem, missing the purpose entirely.

The problem:

When the A3 is reduced to a box-filling exercise, teams skip the reflection, collaboration, and learning process. The A3 becomes static, rather than evolving with insights, feedback, and real-world observations.

How to uncover the full potential of A3 reports in Lean?

A3 method integrates tools like PDCA, 5 Whys, and process mapping -making it a flexible framework rather than a static report. Adopt the A3 as a thinking process, not a reporting format. Use it as a collaborative tool during daily meetings, improvement initiatives, and project planning. Ensure teams walk through each section thoughtfully; from defining the problem to reviewing results, rather than rushing to complete a form.

2. Inadequate root cause analysis

Jumping to conclusions? A rushed or surface-level root cause analysis often leads to ineffective solutions that don’t last.

The power of A3 in root cause analysis:

A properly used A3 is a powerful tool for uncovering root causes. By prompting users to define the current condition, identify gaps, and explore causes, it naturally supports structured problem-solving techniques like the 5 Whys, Fishbone diagram (Ishikawa), and Pareto analysis.

Where it goes wrong:

Many teams perform shallow analysis that treats symptoms as causes. Without structured tools or Gemba-based validation, countermeasures become guesswork, leading to recurring issues.

How to strengthen root cause analysis in A3 process:

Dig deeper. Use root cause tools during the analysis stage and verify your assumptions with data from the actual workplace. Incorporate proven techniques such as:

- Use the 5 Whys to drill down to the root issue.

- Map causal factors with a Fishbone diagram.

- Validate frequency or impact with a Pareto chart.

These tools fit perfectly within the A3 structure and reinforce the PDCA approach by ensuring causes are understood before moving to solutions.

3. Overcomplicating the A3 template

What makes A3 document effective:

A3s work because they simplify complexity. By capturing a problem and its resolution on one page, they force teams to be selective, visual, and focused.

Where complexity creeps in:

Overloaded with text, technical language, or unfiltered data, some A3s become hard to read and harder to use. This undermines the clarity and quick decision-making A3s are supposed to support.

What to aim for:

The A3 should communicate the essence of the problem and the solution. It’s a visual map of thinking, not a data dump.

How to simplify your A3 reports for better decision-making?

Stick to the Lean principle of clarity. Use short statements, sketches, graphs, or trend lines where appropriate. Let the document flow visually across the PDCA stages.

4. Neglecting stakeholder engagement

A3 as a collaborative tool:

Lean problem solving is not a solo activity. A3s are designed to be shared, discussed, and evolved with cross-functional input. The format supports alignment across levels — from operators to senior leaders.

When you go it alone:

A lack of stakeholder involvement leads to blind spots in the problem analysis, weak buy-in, and resistance to implementation. It disconnects the problem from the people who have experienced it.

How to make your A3 methodology collaborative?

Build a habit of collaboration by inviting other to contribute:

- Use the A3 in regular team meetings or Gemba reviews.

- Assign sections to different team members.

- Present and discuss the A3 before finalising countermeasures.

This shared ownership transforms the A3 into a dynamic problem-solving canvas rather than a static form.

5. Applying A3 to all problems

When A3 is most effective:

The A3 method is ideal for complex, recurring, or strategic problems that require cross-functional collaboration, structured analysis, and sustained follow-through.

Misuse in practice:

Applying A3s to minor or routine issues can exhaust teams and dilute the value of the tool. Not every broken machine or late delivery needs a full A3.

What are some alternative tools for A3 for effective problem solving?

Apply problem triaging. Use A3 selectively for strategic, high-impact problems. Train your team to choose the right problem-solving level for each case. Routine issues may be better handled through standard work updates or quick Kaizen. By reserving A3s for meaningful challenges, you protect team energy and keep the A3’s power intact. Use tools like 8D analysis, DMAIC, Value Stream Mapping, Standardised work audits etc. According to the different business problems.

6. Lack of follow-up

A3 after implementing action plan

Many teams stop after implementing the action plan, forgetting the “Check” and “Act” in PDCA. Without follow-up, improvements fade or revert.

Why this undermines results:

Without follow-up, you don’t know whether the issue was resolved, whether new problems emerged, or whether further action is needed. Continuous improvement becomes incomplete improvement.

A3’s role in follow-up:

Sustaining change requires measuring results, reviewing effectiveness, and making adjustments. It’s where real learning happens. The final sections of an A3 are meant to track results and propose further actions

The fix:

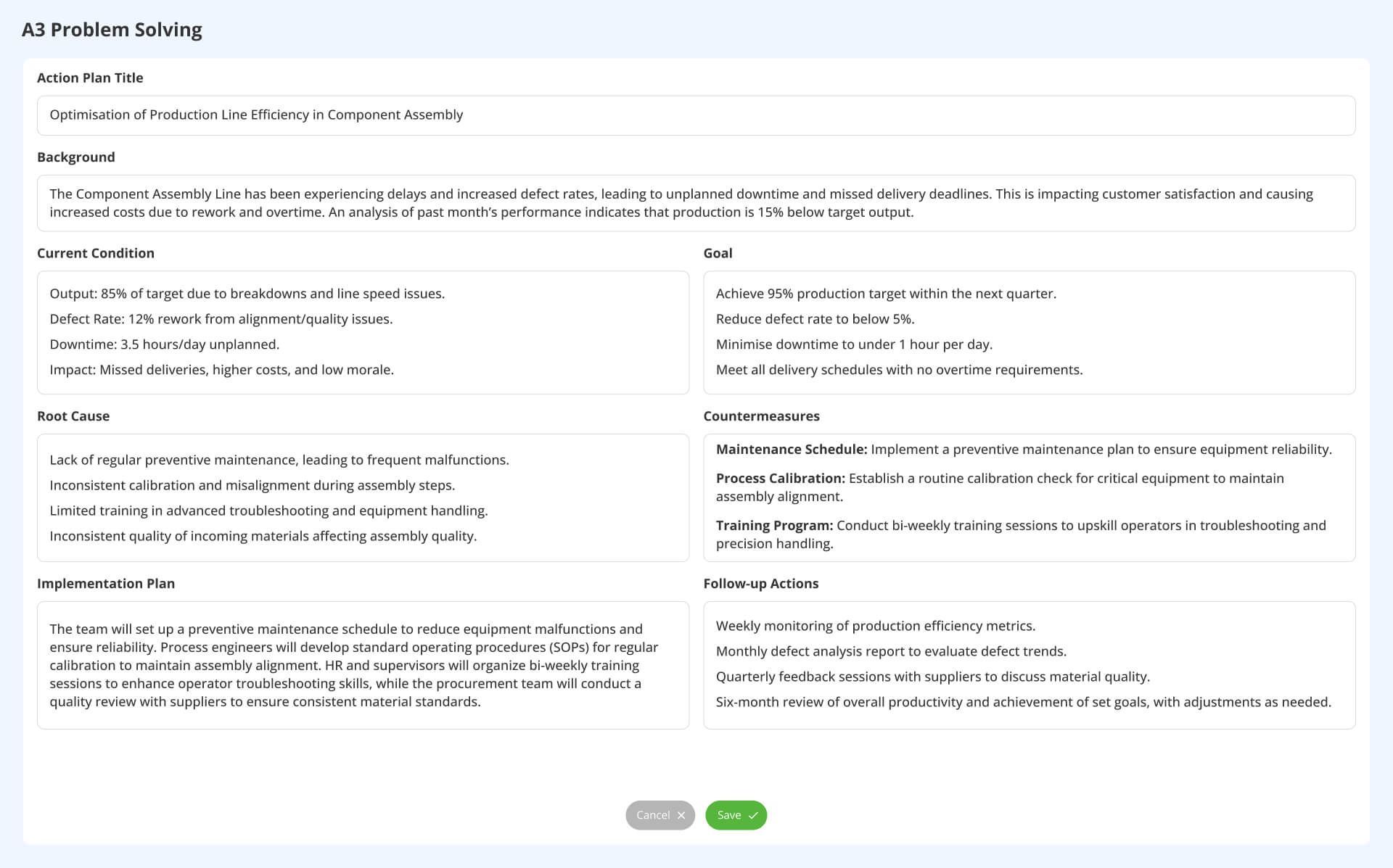

Assign owners for post-implementation reviews. Use digital tools to track status in real time, review KPIs, gather feedback, and revise the plan if needed. Make the A3 a living document, updated as results evolve.

Still printing A3s on paper? Go digital with A3

Traditional A3s are often printed and filed, limiting collaboration, visibility, and long-term access. In contrast, digital A3 platforms support Lean management by enabling real-time updates, historical tracking, integration with metrics, and cross-team access.

The missed opportunity:

Staying paper-based means losing out on version control, KPI dashboards, built-in tools like Fishbone or 5 Whys, and automated reporting.

The Fix:

Upgrade to a digital A3 system that fits your Lean ecosystem. Whether managing strategy deployment, equipment issues, or safety concerns — a digital A3 keeps improvement efforts aligned, visible, and sustainable.

Ensure accuracy in A3 Problem Solving with Data Point

Avoid common mistakes and elevate your problem-solving approach with Data Point Balanced Scorecard