Benefits of digital accountability solutions

- Real-time analytics: Instant access to performance metrics and KPIs

- Automated reporting: Elimination of manual data entry and report generation

- Mobile integration: Access to critical information from anywhere

- Predictive capabilities: Advanced forecasting and trend analysis

- Compliance management: Automated tracking of regulatory requirements

Today’s modern accountability boards are not just digital upgrades — they’re powerful tools designed to bring clarity, consistency, and control to the shop floor. These systems are easy to use, highly customisable, and built to fit the way each team works. Whether you're tracking production accountability, real-time performance, or team KPIs, these boards give everyone a shared view of what’s happening, what’s on track, and what needs action. Want to enhance your shop floor accountability? Learn the impact of a modern real-time responsibility tracker and how to implement it.

Impact of accountability boards on organisational operational excellence

- Enhanced visibility: Provide real-time visibility into production metrics.

- Improved communication: Facilitate better communication between shifts, departments, and management levels.

- Data-driven decision making: Transform raw data into actionable insights with advanced analytics.

- Performance optimisation: Regular monitoring and tracking leads to continuous improvement.

- Mitigate risks: Automated alerts and trend analysis notify teams to identify risks at an earlier time.

- Drives continuous improvement: Regular reviewing and recording essential data helps for long term growth and sustaining success.

Curious how it all comes together — from placing a digital accountability board to turning insights into action? Let’s take a closer look at how modern operational control systems work in the production area.

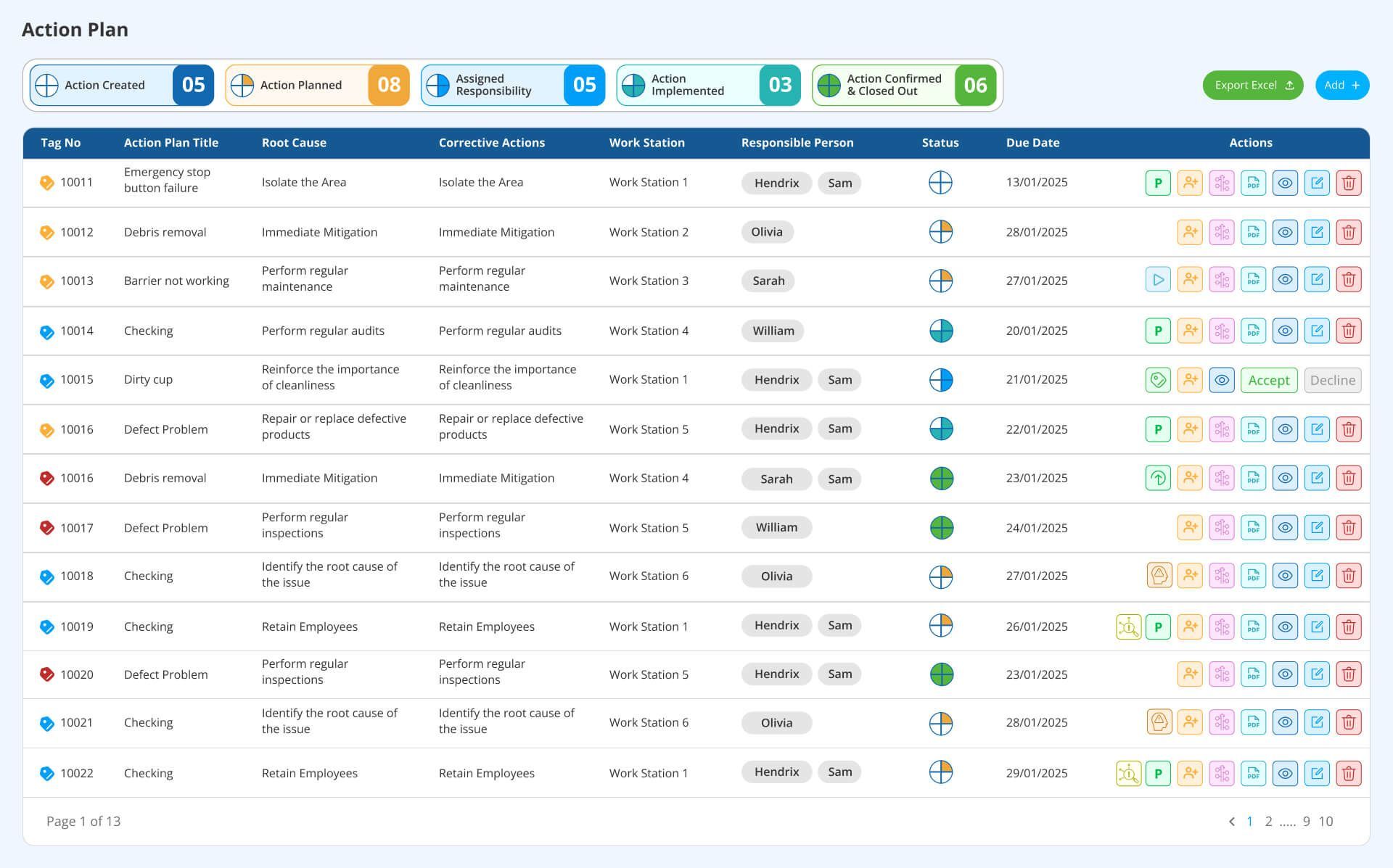

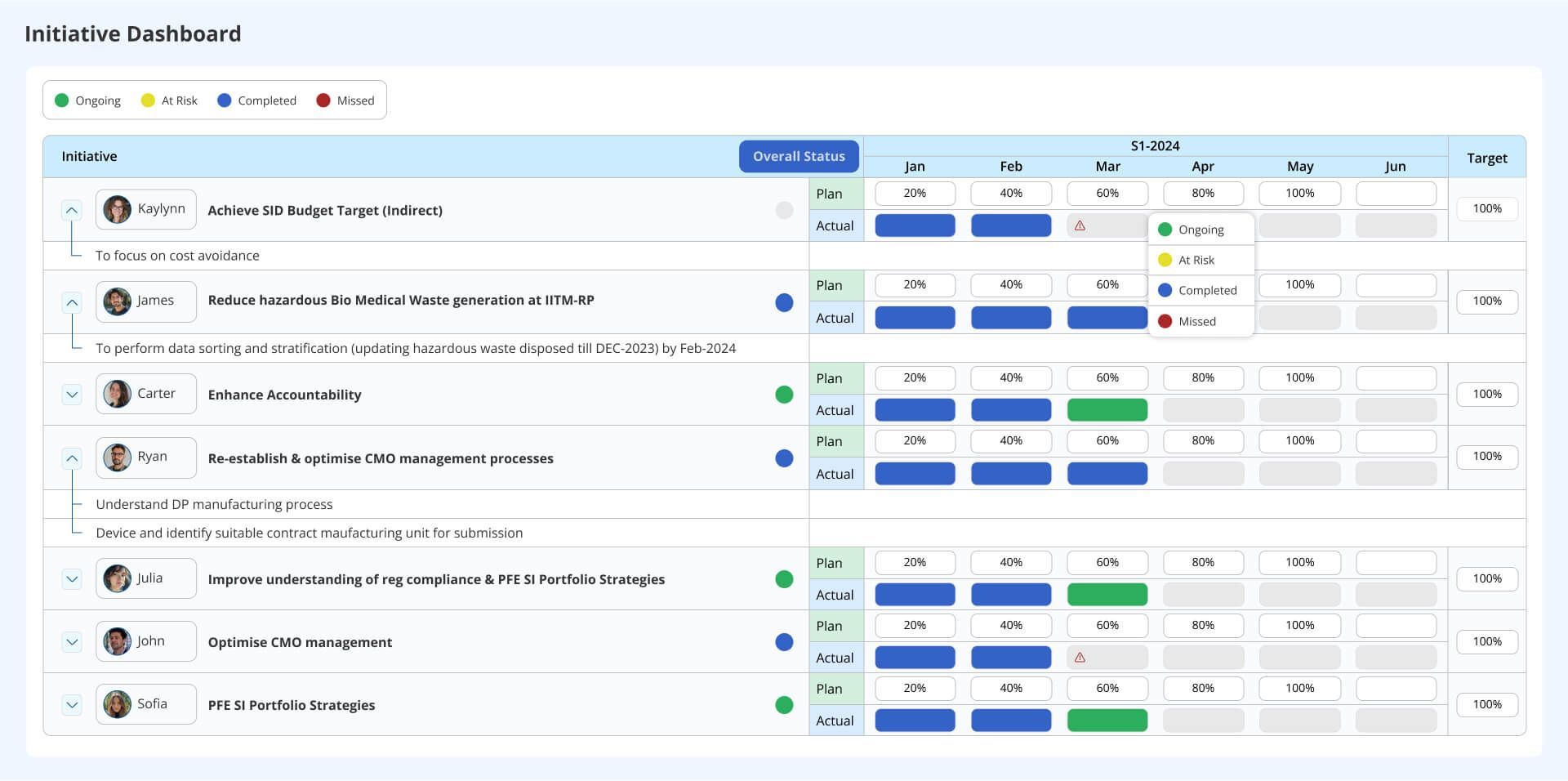

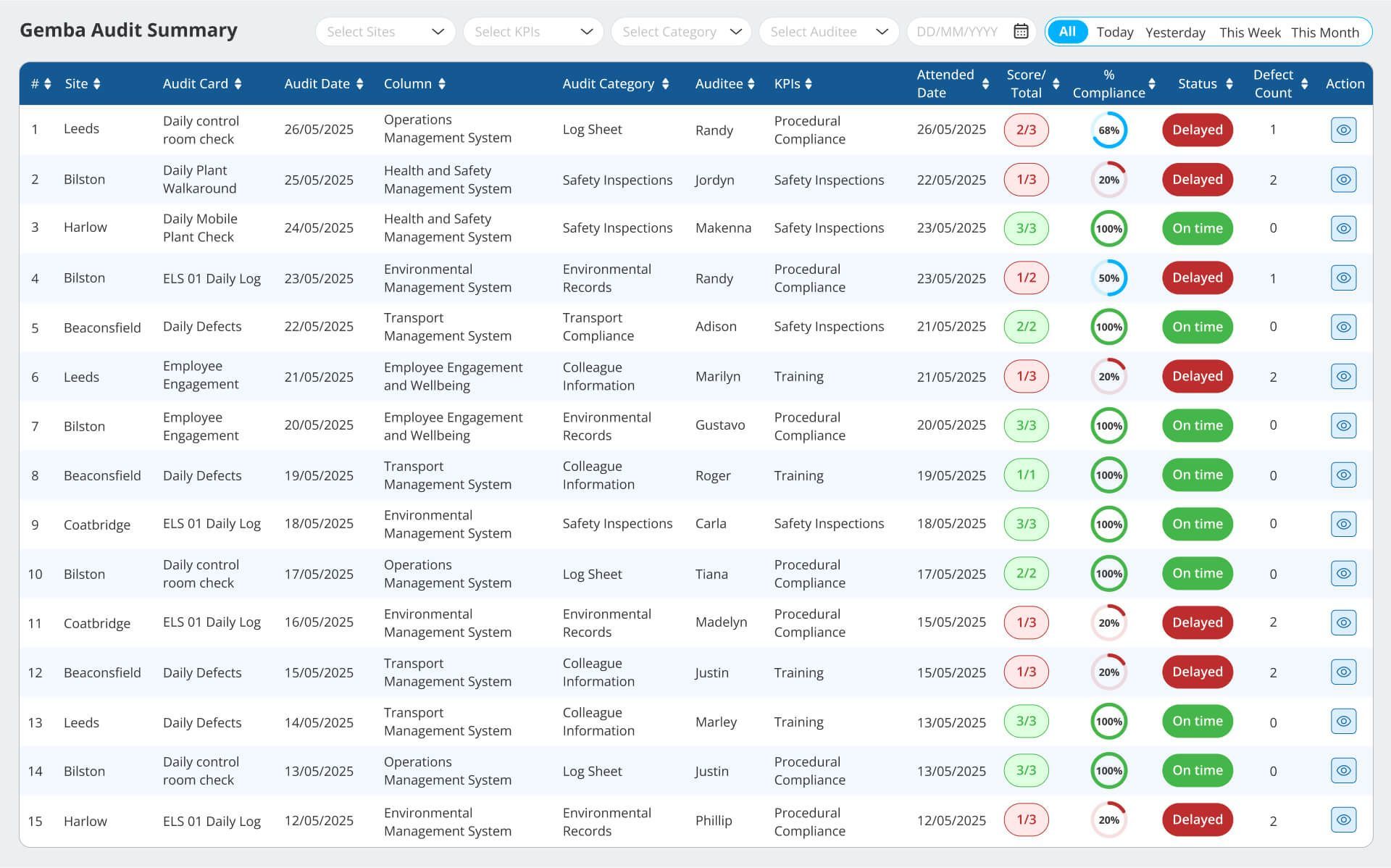

Here is an example of manufacturing accountability tracking. In practice, teams often use different dashboards such as a PDCA dashboard, metrics dashboard or huddle board, escalation dashboard, KPI analytical dashboard, initiative dashboard, or a tiered performance dashboard — each designed to make accountability clear and action-focused.

1. Placed where it matters most

The digital accountability board or the accountability tracking screen is set up in key shop floor zones filled with relevant Key performance indicators of your process. These zones include assembly lines, workstations, or control rooms — where visibility is crucial and easily accessible to everyone.

2. Used by everyone, every day

Team members start their shift by reviewing the board. Daily goals, open issues, and assigned responsibilities are all clearly displayed. Supervisors use it during team huddles or Gemba walks to discuss updates and actions.

3. Live data = Instant insights

With automatic data feeds from machines or manual inputs via tablets, the board updates in real time. Accountability tracking systems highlight delays, quality drops, or missed targets instantly that give teams the chance to act, not react.

4. Driving results over time

As teams use the board consistently, problems are caught early, responsibilities stay clear, and performance trends become visible. This not only improves daily operations but also builds a culture of ownership and transparency.

5. Boosting overall efficiency

With improved communication, faster issue resolution, and production monitoring dashboards, teams operate with greater alignment and less downtime. This leads to measurable improvements in productivity, quality, and employee engagement.

Key features of modern accountability tracking software

- Cloud-based accessibility

- Interactive dashboards

- Custom KPI tracking

- Integration capabilities with existing systems

- Advanced reporting tools

Visual management

- Interactive dashboards

- Color-coded status indicators

- Customisable layouts

Real-time monitoring

- Live production metrics

- Instant alert systems

- Performance tracking

Quality control

- Defect tracking

- Quality metrics visualisation

- Compliance monitoring

Building smart factories: The role of visual accountability system in industry 4.0

Industry 4.0 isn’t just about machines talking to each other — it’s about creating connected, responsive, and intelligent manufacturing systems. And at the center of this transformation lies one critical factor: accountability.

In smart factories, accountability is not a manual checklist — it’s built into the system. Modern real-time accountability tracking solutions help organisations not only collect data but also assign responsibility, monitor actions, and ensure follow-through at every level.

- Accountability enables traceability

Every action, delay, or deviation is tracked, allowing teams to trace back to the root cause quickly.

- It drives system responsiveness

With real-time tracking and role-based access, issues are escalated and resolved without delay.

- It ensures alignment

Smart accountability systems link frontline tasks to strategic goals, supporting agile and informed operations.

- It boosts compliance and standardisation

Consistent tracking builds strong audit trails, supporting safety, quality, and operational standards.

Accountability systems in the Industry 4.0 stack

Modern manufacturing operations use layered technology stacks — and digital accountability tools now form a crucial part of that infrastructure. They integrate with:

- Manufacturing Execution Systems (MES) for real-time updates

- Enterprise Resource Planning (ERP) platforms to connect goals and actions

- KPI visualisation dashboards for performance benchmarking

- IoT-driven equipment that provides instant machine-level data

This integration allows decision-makers to not only see what’s happening — but also see who is responsible, what actions were taken, and what’s pending.

Build your smart factory with Data Point accountability boards