FAQs

1. Which KPIs are essential in aviation component manufacturing?

Top indicators include On‑Time Delivery (OTD), first‑pass yield, scrap/rework rate, Mean Time Between Failures (MTBF), and supplier performance—providing a balanced view across quality, delivery, cost, and reliability.

2. What KPIs do airlines track for operational efficiency?

Airlines commonly track On‑Time Performance (OTP), Turnaround Time (TAT), aircraft utilisation rate, load factor, fuel efficiency, and baggage handling performance

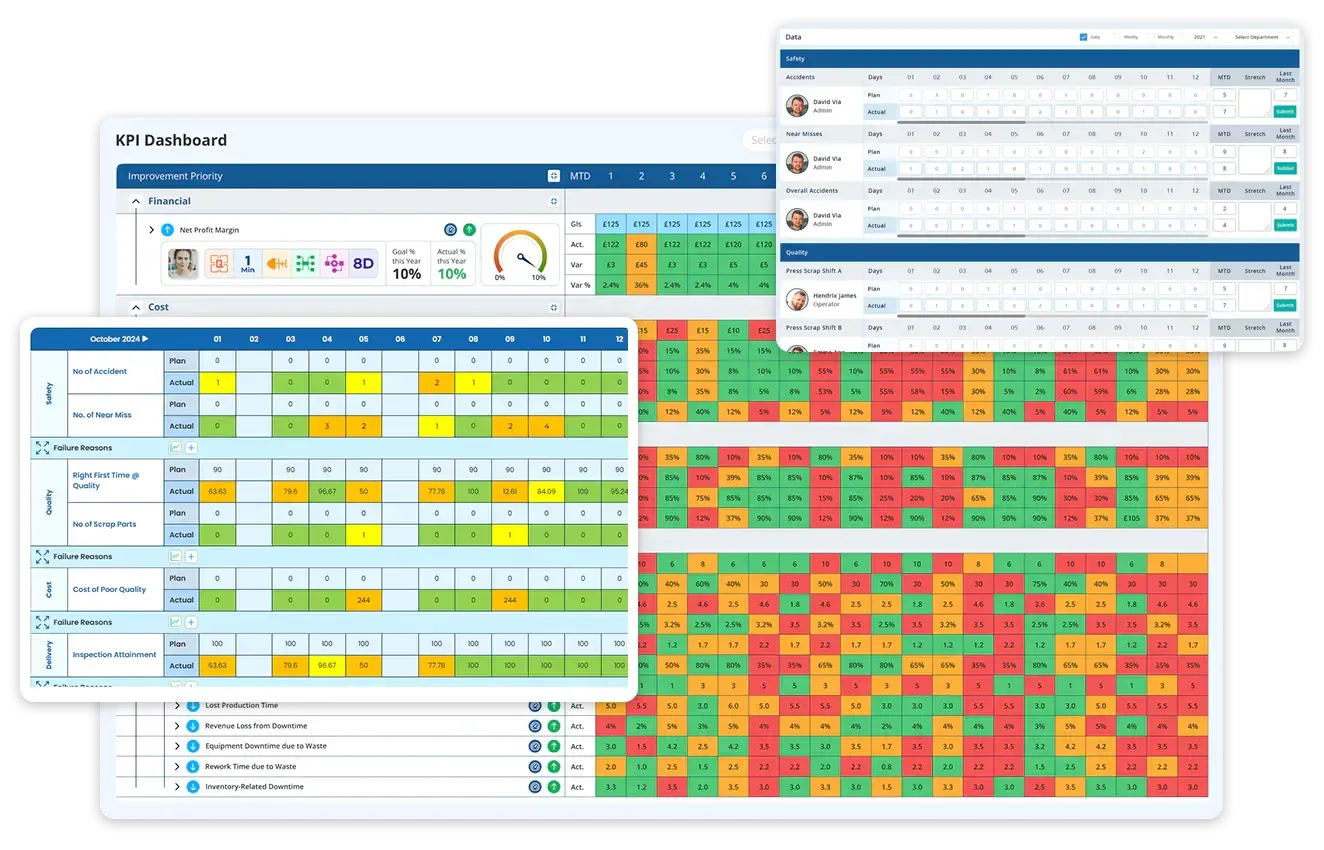

3. How do KPI dashboards support aviation quality & compliance?

Dashboards support audit trail reporting, tracking safety KPIs, monitor non‑conformance, and generate exportable compliance data to reduce manual efforts.

4. What role do visual management tools play in aerospace lean operations?

Visual tools like SQCDP boards and daily management charts help teams review safety, quality, cost, delivery, and people metrics each shift—boosting problem detection and lean engagement.

5. How often should aviation manufacturing KPIs be reviewed?

Operational metrics like OEE or downtime should be reviewed daily, team targets weekly, and strategic KPIs (e.g., supplier quality) monthly.

6. Can aviation legacy systems integrate with modern KPI dashboards?

Yes. Modern dashboards frequently integrate with ERP/MES systems such as SAP or Oracle, even when older legacy systems are present.

7. Are aviation KPI dashboards scalable across sites and suppliers?

Absolutely. Dashboards can be customised per site, supplier, or function (manufacturing, procurement, quality), yet maintain centralised visibility.

8. What lean methodologies do aviation dashboards support?

Dashboards support lean tools like Kaizen, PDCA cycles, SQCDP, and continuous improvement routines integrated into daily workflows.

9. Is Data Point customisable for different aerospace suppliers or MROs?

Absolutely. Whether you're a Tier 1 manufacturer, Tier 2 supplier, or MRO service provider, Data Point is fully configurable to your KPIs, workflow, and compliance needs. It scales across sites and departments while maintaining a clear line of sight to strategic goals.