Mastering KPIs for Operations Managers: What to Track and What to Skip

Last updated on : January 6, 2026

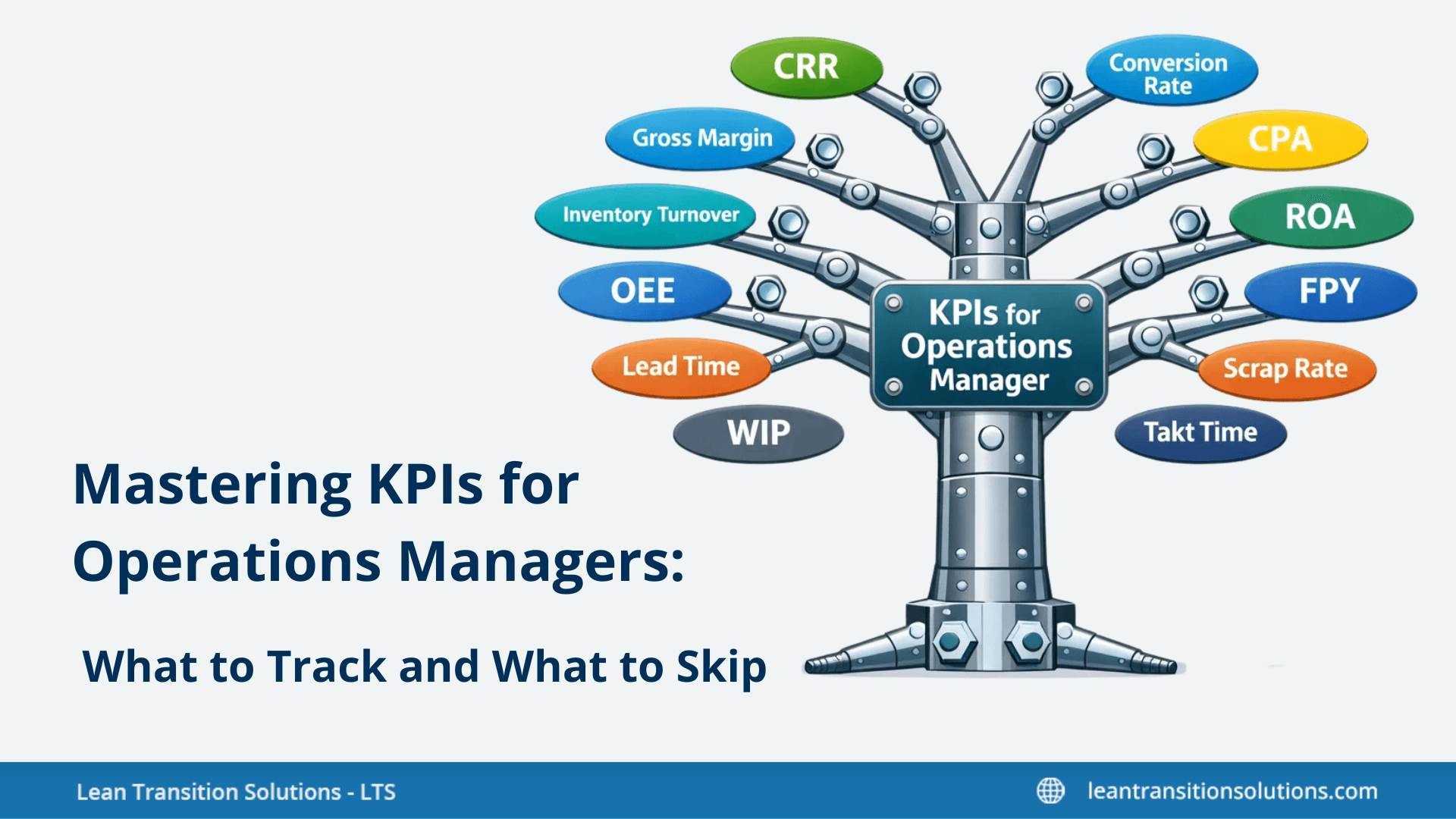

Let’s face it — being an operations manager isn’t easy. You’re expected to keep everything running smoothly, cut costs, boost efficiency, and still hit your targets. With so much data flying around, it’s hard to know what to focus on. That’s where smart KPIs come in but only if you’re tracking the right ones. LTS Data Point makes this easier by giving you a clear, digital scorecard that helps you monitor what matters, spot issues early, and keep your team aligned with business goals. In this blog, we’ll look at the KPIs that really count and how to avoid the common mistakes that can hold your operations back.

The role of KPIs: Why do they matter?

Key Performance Indicators (KPIs) are metrics that can be calculated in numerical terms which reflect how effectively an organisation is achieving its strategic and operational goals.