Last updated on : February 25, 2026

Operational excellence isn't achieved through occasional improvement projects or annual strategy sessions. It's built through disciplined daily practices, clear visibility into performance, and systems that turn data into action.

So why many organisations fail in enhancing their operational excellence? It is because of the absence of connected systems that make operational excellence sustainable. Manual boards become outdated. Spreadsheets multiply across departments. Strategic goals disconnect from shop floor reality. Actions get logged but never closed.

This is where operational excellence software transforms how organisations operate. Among the top-rated operational excellence tools available today, LTS Data Point stands out as a comprehensive operational excellence management software adaptable across manufacturing, pharmaceuticals, aerospace, construction, mining, healthcare, food processing, energy, printing, and automotive industries.

But before diving into specific solutions, understanding what operational excellence truly means and how modern OPEX software enables it matters more.

Quick answer: What makes operational excellence software essential?

In brief: Operational excellence software creates real-time visibility into performance, structures daily management through tier meetings, embeds systematic problem-solving tools, and connects boardroom strategy to shop floor execution. It replaces manual boards and spreadsheets with connected digital systems that drive accountability and continuous improvement.

Best for: Manufacturing, pharmaceuticals, construction, aerospace, and service organisations with 100+ employees managing multiple departments or sites.

Key outcome: Organisations typically save 20-40% in meeting time while improving KPI performance by 15-30% within the first six months. One manufacturer reported saving over £151,000 annually from meeting time reduction alone, based on 71 executive attendees.

Implementation timeline: Most operational excellence software deployments complete initial setup in 4-8 weeks, with full organisational adoption occurring within 3-6 months.

What is an operational excellence software?

Operational excellence software is a digital platform that helps organisations manage, track, and improve performance across departments, sites, and shifts in real time. Unlike generic business intelligence tools that analyse historical data, operational excellence management software drives daily execution, structures communication, and enables systematic improvement.

The platform brings together KPIs by KPI tracking, daily management routines, problem-solving methodologies, and strategic planning in one connected system. It supports tier meetings, visual management boards, root cause analysis, action tracking, and continuous improvement practices like Lean and Six Sigma.

To understand what truly defines effective operational excellence software, it is important to look beyond the definition and explore the 15 must-have features in operational excellence software and the best practices to use it.

Most importantly,

Understanding the operational excellence framework

The operational excellence framework provides structure for how organisations systematically execute strategy through aligned processes, engaged people, and disciplined improvement. An operational excellence manager implementing this framework needs more than methodology knowledge—they need enabling systems that make excellence sustainable.

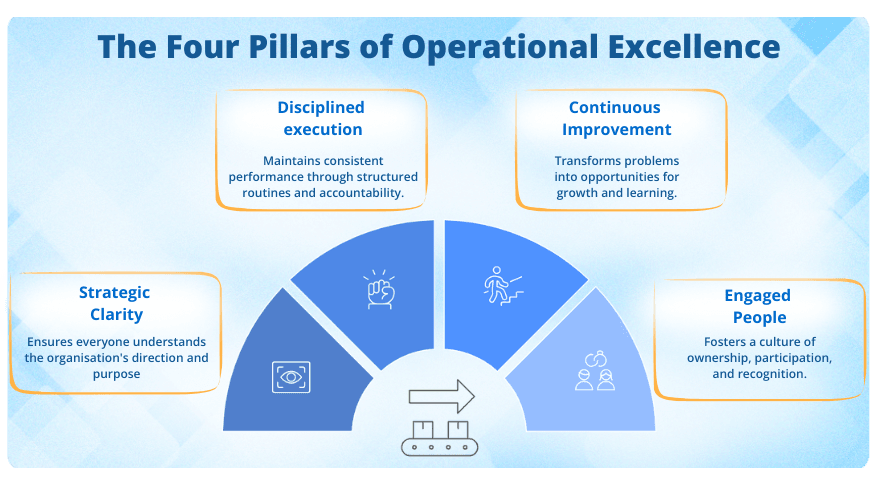

The 4 Pillars of operational excellence

Understanding the 4 pillars of operational excellence clarifies what any OPEX software must support:

Pillar 1: Strategic clarity

Everyone understands where the organisation is heading and why their work matters. Strategy cascades from boardroom to breakroom through visual connections that make sense to frontline teams. Manufacturing excellence software creates this visibility through Hoshin Kanri matrices and objective flow charts.

Pillar 2: Disciplined execution

Daily management routines ensure consistent performance. Tier meetings happen on schedule. KPIs get reviewed systematically. Issues escalate promptly. Actions close with documented results. This discipline separates excellent operations from average ones.

Pillar 3: Continuous improvement

Problems become improvement opportunities rather than recurring frustrations. Root causes get addressed, not symptoms. Learning spreads across the organisation through standardised problem-solving embedded in operational excellence tools.

Pillar 4: Engaged people

Teams understand their performance, own their outcomes, and participate actively in making things better. Accountability is clear with accountability tracking systems. Recognition is meaningful. Development is intentional. Engagement drives sustainable excellence.

Why do manual systems or Excel operational excellence tracking fail?

Most organisations start their operational excellence journey with whiteboards, Excel spreadsheets, and good intentions. These tools work initially but break down as operations scale. Know Why Operations Meetings Fail And What High-Performing Teams Do Differently here.

- Whiteboards require manual updates that lag reality. Someone must gather data, calculate metrics, and change numbers with markers. By the time updates happen, the information is already outdated. Remote teams can't see the boards. Historical trends require photographing boards before erasing them.

- Excel spreadsheets proliferate across departments, each with slightly different formats and formulas. Version control becomes impossible. Finding current data wastes time. Consolidating information for leadership requires manual aggregation prone to errors.

- Email threads track actions until they don't. Messages get buried. Follow-ups get forgotten. Accountability disappears into overflowing inboxes.

This fragmented approach creates the operational excellence paradox: organisations work harder but see diminishing returns because systems can't support sustainable improvement.

How operational excellence software transforms daily operations?

Modern operational excellence software solves these fundamental problems by creating a single, connected platform where strategy, execution, and improvement converge.

Real-time visibility replaces delayed reporting

Let us take an example of operational excellence tracking system in manufacturing sector. Manufacturing excellence software and OPEX tools pull data automatically from existing systems—ERP platforms, manufacturing execution systems, quality management software, maintenance tools. Dashboards update continuously, showing current performance rather than historical snapshots.

When a production line misses takt time, the operational excellence software flags it immediately. When quality metrics drift toward specification limits, alerts notify relevant teams. When actions approach deadlines, reminders go out automatically.

This shift from periodic reporting to continuous visibility fundamentally changes management behaviour. Instead of reviewing what happened last week, teams respond to what's happening right now.

What is a tier management system and what is the role of OPEX software in it?

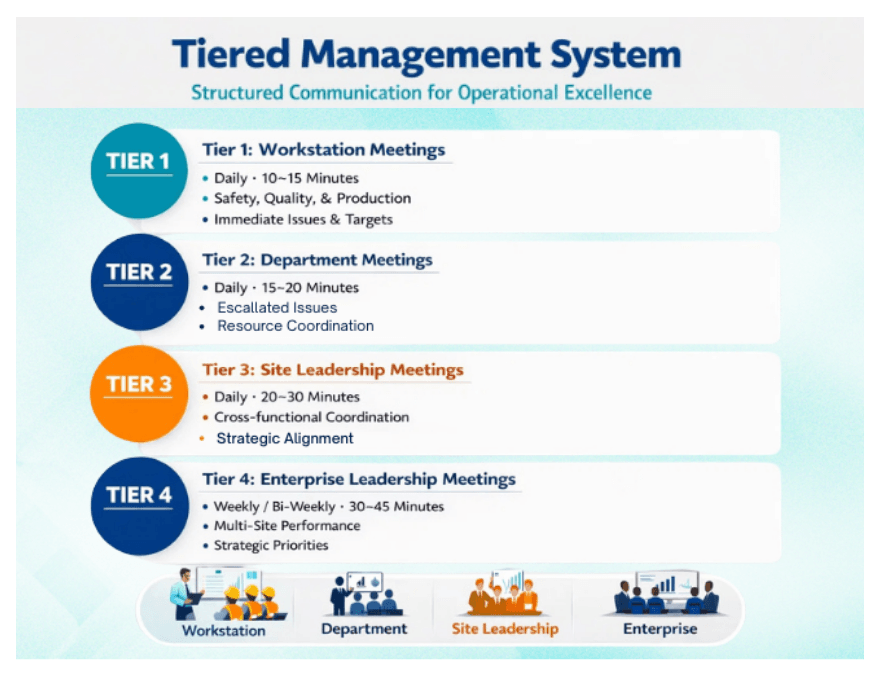

A tier management system structures organisational communication through levels, creating one of the most powerful operational excellence tools and techniques.

Tier 1 meetings happen at workstations reviewing immediate performance. Operators discuss safety observations, quality issues, production targets, and immediate concerns. Duration: 10-15 minutes. Frequency: Daily at shift start.

Tier 2 meetings cover departments consolidating multiple workstations. Supervisors review aggregated performance, address escalated issues from Tier 1, and manage resources across areas. Duration: 15-20 minutes. Frequency: Daily mid-morning.

Tier 3 meetings involve site leadership reviewing overall performance. Plant managers address systemic issues, ensure alignment with strategic goals, and allocate resources to improvement initiatives. Duration: 20-30 minutes. Frequency: Daily early afternoon.

What is Value Stream Mapping in operational excellence?

Value stream mapping documents every step in a process from customer request to delivery, identifying value-added activities versus waste. Traditional VSM creates static diagrams on paper showing current state and future state.

In operational excellence software, digital value stream mapping transforms this from a one-time exercise into living documentation. Teams map processes directly in the OPEX software, linking each step to actual performance data. Lead times, cycle times, quality rates, and waste metrics update automatically based on real operations.

This dynamic approach makes waste visible continuously rather than during occasional improvement events. Process owners see bottlenecks as they develop, quality issues as they emerge, and efficiency trends as they change. Digital VSM connects process documentation to daily management, turning value stream mapping from an analysis tool into an operational tool.

How operational excellence software ensures problem solving?

Operational excellence software ensures effective problem solving by identifying issues in real time, assigning clear ownership, and tracking actions through to closure. It conatins embedded tools and frameworks designed to support each function, from problem identification to root cause analysis and corrective action.

What are the embedded tools in an operational excellence system for problem solving?

- Fishbone diagrams help teams identify potential causes systematically across categories like methods, materials, machines, measurement, people, and environment. The visual structure prevents teams from jumping to conclusions.

- Pareto analysis reveals which problems drive the biggest impact. By focusing improvement efforts on the vital few rather than the trivial many, teams maximise return on improvement time.

- 5 Whys investigation traces issues to root causes rather than stopping at symptoms. Each "why" digs deeper until the fundamental cause emerges.

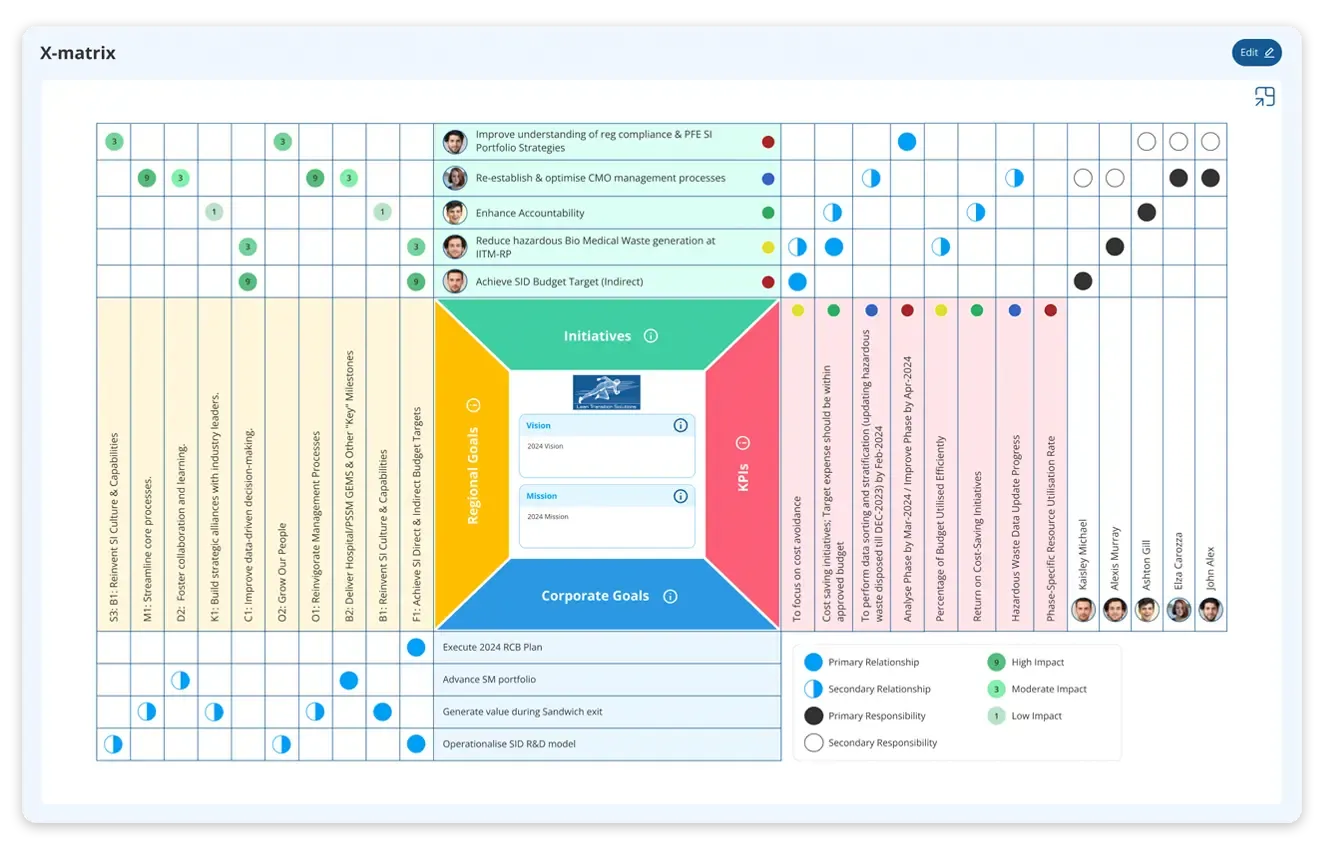

How the operational excellence software ensures strategic alignment?

Hoshin planning with digital X-matrix tools and strategy maps within OPEX software connect long-term vision to annual objectives to quarterly initiatives to weekly activities. Every team member sees how their work contributes to organisational goals.

Bowling charts track progress toward annual targets month by month, making trends visible early. Objective flow charts show dependencies between initiatives. KPI dashboards at every tier reflect relevant metrics for each level.

This visibility prevents the common disconnect where leadership discusses strategy while frontline teams wonder how it relates to their daily work.

What are the most important operational excellence metrics to track?

Operational excellence metrics provide the foundation for performance management. The specific metrics vary by industry, but certain categories remain consistent across organisations.

Safety metrics

Safety always comes first in the operational excellence framework. Organisations track:

- Incident rate (injuries per 200,000 hours worked)

- Near miss reporting frequency

- Safety observation completion

- Days since last recordable incident

- Leading indicators like hasard identification and safety training completion

For Manufacturing excellence, OPEX software makes safety metrics visible at every tier, ensuring teams address concerns before incidents occur.

What are the benefits of having operational excellence software in organisation?

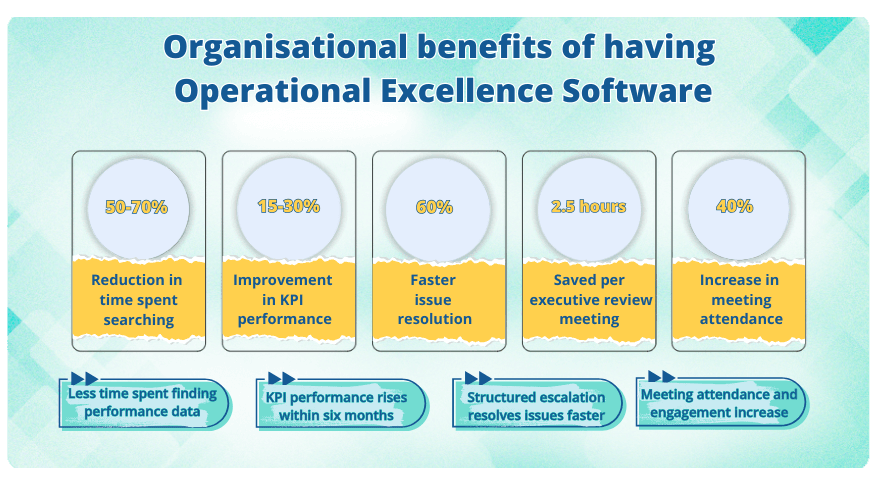

Organisations using operational excellence software report:

- 2.5 hours saved per executive review meeting

- 50-70% reduction in time spent searching for performance data

- 15-30% improvement in KPI performance within first six months

- 60% faster issue resolution through structured escalation

- 40% increase in meeting attendance and engagement

Operational excellence software vs traditional methods: Key differences

7 Steps to implement operational excellence software successfully

Assess your current state

Document existing processes, pain points, and manual systems that need replacement. Walk your operations asking: Where does data live? How do teams communicate? What problems recur? Where do actions get lost?

Timeline: 1-2 weeks with cross-functional input

Define success metrics

Identify which operational excellence metrics matter most to your organisation. Don't track everything. Track what connects to strategic goals and drives decisions. Typically, 15-25 KPIs per tier level provides sufficient visibility without overwhelming teams.

Timeline: 1 week with leadership alignment

Map your tier structure

Determine how many tier levels you need and who participates at each. Most organisations need 3-4 tiers. Define meeting frequency, duration, participants, and escalation protocols for each tier.

Timeline: 1-2 weeks including workflow design

Select your OPEX software

Evaluate operational excellence tools based on the 15 essential features outlined below. Request demonstrations with actual end-users, not just managers. Test mobile accessibility. Verify integration capabilities with your existing systems.

Timeline: 4-6 weeks including vendor evaluation and selection

Plan your integration

Identify which systems (ERP, MES, QMS, maintenance software) must connect to your operational excellence software. Document data flows, update frequencies, and security requirements. Assign technical resources for integration work.

Timeline: 2-3 weeks for planning, 4-6 weeks for execution

Start with a pilot

Deploy manufacturing excellence software in one department or site to prove value before scaling. This builds confidence, identifies issues, and creates internal champions who help with broader rollout.

Timeline: 6-8 weeks for pilot deployment and validation

Expand systematically

Roll out across additional areas using lessons learned from your pilot. Provide training at each location. Adjust dashboards based on feedback. Celebrate early wins to build momentum.

Timeline: 3-6 months for full organisational deployment

Total implementation timeline: Most organisations complete the full journey in 6-9 months from initial assessment to enterprise-wide adoption.

Operational excellence examples across industries

Understanding how operational excellence software works in practice clarifies its value.

Pharmaceuticals

Operational excellence managers in pharmaceutical manufacturing use OPEX software to centralise QA metrics, track deviations in real time, and maintain GxP compliance documentation. When batch quality drifts, the system alerts supervisors immediately. Root cause investigations follow structured 8D methodology. Audit trails provide complete traceability.

Automotive manufacturing

Automotive operations implement tier view management through operational excellence tools. Morning huddles at each workstation review safety incidents, quality escapes, and production targets. Supervisors consolidate this information for department reviews. Plant managers see site-wide performance. Issues escalate systematically with full context.

Construction

Construction companies managing multiple sites use digital operational excellence system to unify project KPIs across locations. Site managers update safety observations, progress milestones, and resource needs through mobile devices. Leadership dashboards show performance across all projects. Structured daily stand-ups keep distributed teams aligned.

Aerospace manufacturers

Aerospace or aviation manufacturers employ operational excellence consulting principles embedded in their OPEX software. Complex product development requires coordination across engineering, production, and quality functions. Digital visual boards show essential Aerospace or aviation KPIs and milestone progress. CAPA workflows track corrective actions. Skills matrices ensure critical competencies remain available.

These operational excellence examples share common patterns: real-time visibility, structured communication, systematic problem-solving, and clear accountability enabled by connected operational excellence tools.

Do you need operational excellence consulting or software?

How to gain operational excellence in business?

Achieving operational excellence requires commitment, discipline, and the right tools working together.

- Start with leadership alignment. The operational excellence framework must have visible executive sponsorship. Leaders must commit to reviewing performance regularly and holding teams accountable.

- Define clear operational excellence metrics relevant to your business. Don't track everything. Track what matters and connects to strategic goals.

- Implement structured daily management through tier meetings. Start small with one area, if necessary but start consistently.

- Deploy operational excellence tools that support your framework. Manual systems can't scale. OPEX software creates sustainability.

- Build problem-solving capability through training and practice. Use the operational excellence tools and techniques embedded in your software.

- Make it about people, not just process. Engaged teams drive operational excellence. Recognition, development, and meaningful work matter.

- Measure progress and celebrate wins. Show teams how operational excellence metrics improve. Share operational excellence examples from your own organisation.

- The journey takes time, but organisations that commit to this path see measurable improvements in safety, quality, delivery, cost, and engagement.

How to choose the right operational excellence software for your business?

Selecting OPEX software requires systematic evaluation against your specific needs and organisational context.

Identify your primary pain point

Start by asking: "What's our biggest operational challenge?" Common answers include:

- Poor visibility into current performance

- Teams working in silos with minimal coordination

- Inconsistent processes across shifts or locations

- Problems recurring despite firefighting efforts

- Strategic goals disconnected from daily activities

- Actions logged but never completed

- Too much time spent gathering data, not enough analysing it

Your primary pain point determines which features matter most in operational excellence tools.

Determine your must-have features

Based on your pain point, prioritise capabilities:

- If visibility is the issue, real-time dashboards and system integration become essential

- If coordination is the problem, tier management and multi-site support move to the top

- If improvement is stalled, root cause analysis tools and action tracking become critical

- If strategy execution is weak, Hoshin Kanri and objective flow charts become necessary

Don't get distracted by comprehensive feature lists. Focus on what solves your specific problems.

Assess integration requirements

List every system that holds performance data: ERP, MES, quality systems, maintenance software, time tracking, environmental monitoring. Your operational excellence software must connect with these seamlessly.

Ask vendors:

- Which systems have pre-built connectors?

- How much custom integration work is required?

- Who performs integration—vendor, you, or third party?

- What's the typical integration timeline?

- How are security and data governance handled?

Integration complexity often determines implementation success. Simple demonstrations hide integration challenges that emerge during deployment.

Consider your team's technical capability

Choose operational excellence tools with interfaces your team can use without extensive training. Request demonstrations with actual end-users, not just managers or IT staff.

Evaluate:

- How intuitive is data entry and dashboard navigation?

- Can non-technical users create custom views and reports?

- Does mobile access work smoothly on tablets and phones?

- How much training is required for different user roles?

- What ongoing support is available?

The best manufacturing excellence software balances powerful capabilities with user-friendly design. Complex systems get abandoned regardless of their features.

Evaluate vendor support and partnership

Ask about onboarding, training, technical support response times, and ongoing consultation. Implementation support matters as much as the software itself.

Key questions:

- What does onboarding include? (configuration, training, data migration)

- Who provides technical support? (vendor direct, partners, community forums)

- What are response time commitments for different issue severities?

- How are software updates and new features delivered?

- What customer success resources are available?

Organisations succeed with operational excellence software when vendors act as long-term partners, not just software vendors collecting license fees.

Calculate total cost of ownership

Include licensing, implementation, training, integration, and ongoing support. Compare this to the cost of current manual processes, wasted meeting time, and delayed problem resolution.

Consider:

- Initial setup and configuration costs

- User license fees (monthly or annual)

- Integration development and maintenance

- Training for initial and ongoing users

- Technical support and updates

- Opportunity cost of delayed benefits

Many organisations discover that OPEX software pays for itself within 6-12 months through meeting time savings alone, before counting performance improvements.

Decision timeframe: Most organisations complete this evaluation in 4-8 weeks, balancing thoroughness with urgency to address operational challenges.

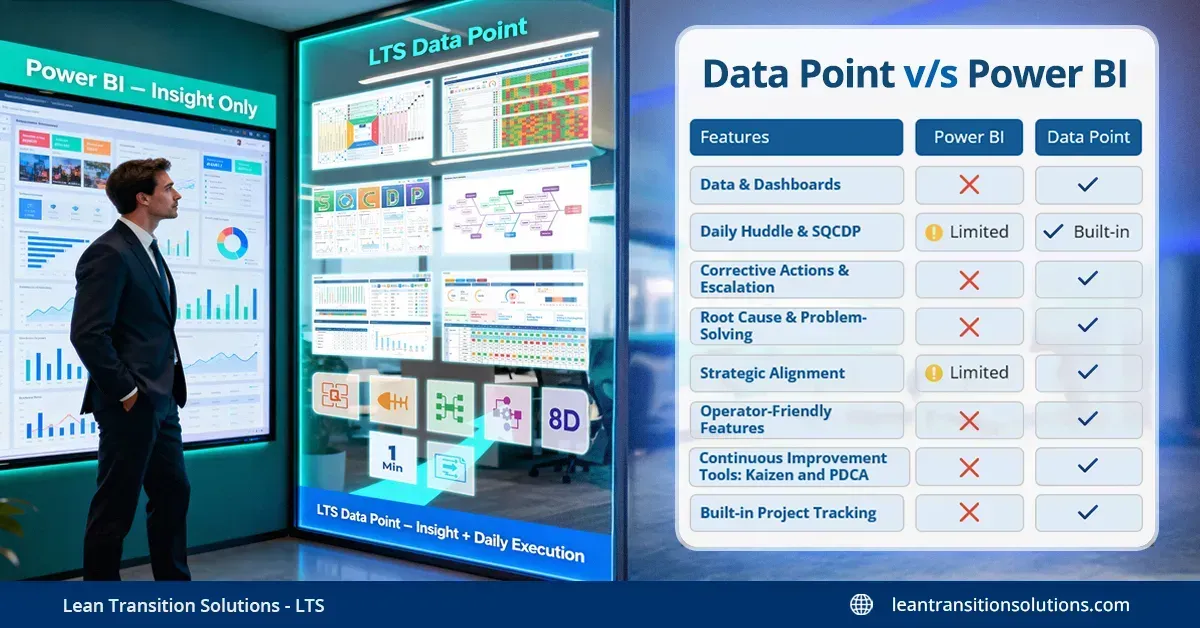

Operational excellence software vs business intelligence tools

Purpose difference: BI tools analyse historical data for insights and strategic decisions. Operational excellence management software drives daily execution, real-time decision-making, and continuous improvement.

User difference: BI tools primarily serve analysts, data scientists, and executives. OPEX software serves everyone from operators to supervisors to plant managers to executives. Each sees relevant information for their role.

Action orientation: BI shows what happened and why, supporting strategic planning. Operational excellence tools show what's happening now and what to do about it, supporting daily management and immediate response.

Meeting support: BI generates reports for monthly executive reviews and quarterly business reviews. Operational excellence software enables daily huddles, tier meetings, and weekly improvement reviews.

Data latency: BI tools typically work with data refreshed daily, weekly, or monthly. Operational excellence software requires real-time or near-real-time updates for effective daily management.

Problem-solving: BI identifies problems through analysis. Operational excellence tools provide structured methodologies (5 Whys, fishbone, 8D) to solve problems and track countermeasures.

Best use: Deploy both. Use BI for strategic analysis, market trends, and complex data science. Use operational excellence software for daily management, performance accountability, and continuous improvement execution. Integration between the two creates powerful synergy—BI identifies opportunities, OPEX software drives implementation.

Example: Comparing LTS Data Point operational excellence software with Power B

For deeper insights, read the comparison of operational excellence software and BI tool: How LTS Data Point supercharges Power BI limitations

Why LTS Data Point represents top-rated operational excellence software

After understanding what operational excellence requires, what the 4 pillars of operational excellence demand, and what features best-rated operational excellence tools must provide, LTS Data Point's position as leading operational excellence management software becomes clear.

Data Point provides the complete operational excellence framework in one connected platform. It supports sustained improvement through real capabilities that drive daily execution, not theoretical features that look good in demonstrations.

Strategic clarity through connected planning

X-matrix templates, objective flow charts, and Hoshin Kanri frameworks connect boardroom strategy to shop floor activities. Every team member sees how their work contributes to organisational goals. Bowling charts track progress toward annual targets month by month, making trends visible early. Strategic dashboards give executives real-time visibility into execution without micromanaging.

Read: 2026 Organisational Strategy Kit by LTS Data Point for more insights.

Disciplined execution through Tier management

Data Point supports structured tier meetings from workstation to enterprise level. Digital SQCDP boards or SQDIP boards replace static whiteboards with live, interactive dashboards. Information flows seamlessly between tiers - escalating upward with context, cascading downward with clarity. Meeting duration drops by 50-70% while decision quality improves because data is current and complete.

Continuous improvement through embedded tools

Value stream mapping, 8D analysis, A3 reports, fishbone diagrams, and Pareto analysis embed proven improvement methodologies into daily workflows. Teams solve problems systematically rather than firefighting symptoms. Complete documentation creates organisational learning—what worked, what didn't, and why.

Regional adoption: Operational excellence software by geography

United Kingdom

High maturity in manufacturing and pharmaceutical sectors drives UK adoption of operational excellence tools. Organisations prioritise GxP compliance support, ISO certification audit trails, and Lean manufacturing integration in their OPEX software selection. Brexit-related supply chain complexity increases demand for real-time visibility across operations.

United States

Large-scale deployments across automotive, aerospace, and industrial manufacturing characterise US adoption. American companies emphasise multi-site coordination, real-time KPI dashboards, and executive visibility. Manufacturing excellence software must integrate with diverse legacy systems accumulated through mergers and acquisitions.

India

Rapid adoption in IT services, pharmaceutical manufacturing, and automotive operations reflects India's growing industrial maturity. Indian organisations focus on scalability, cost-effective deployment models, and mobile accessibility for distributed teams. Government initiatives supporting Lean and digital transformation drive operational excellence software investments.

Canada

Strong uptake in resource industries (mining, energy, forestry) and manufacturing demonstrates Canadian operational excellence focus. Operations prioritise safety metrics, environmental compliance tracking, and performance visibility across geographically dispersed sites. Cold climate challenges make mobile-first OPEX software essential for field operations.

Taking action: Your next steps toward operational excellence

Operational excellence isn't purchased through software licenses. It's built through consistent practice, engaged people, disciplined systems, and leadership commitment. However, the operational excellence software dramatically accelerates this journey.

If your organisation struggles with disconnected data, inconsistent practices, strategic plans that don't reach the shop floor, or improvement initiatives that fade after consultants leave, operational excellence management software solves these fundamental problems.