FAQs

1. What are the most important KPIs for quality managers in manufacturing?

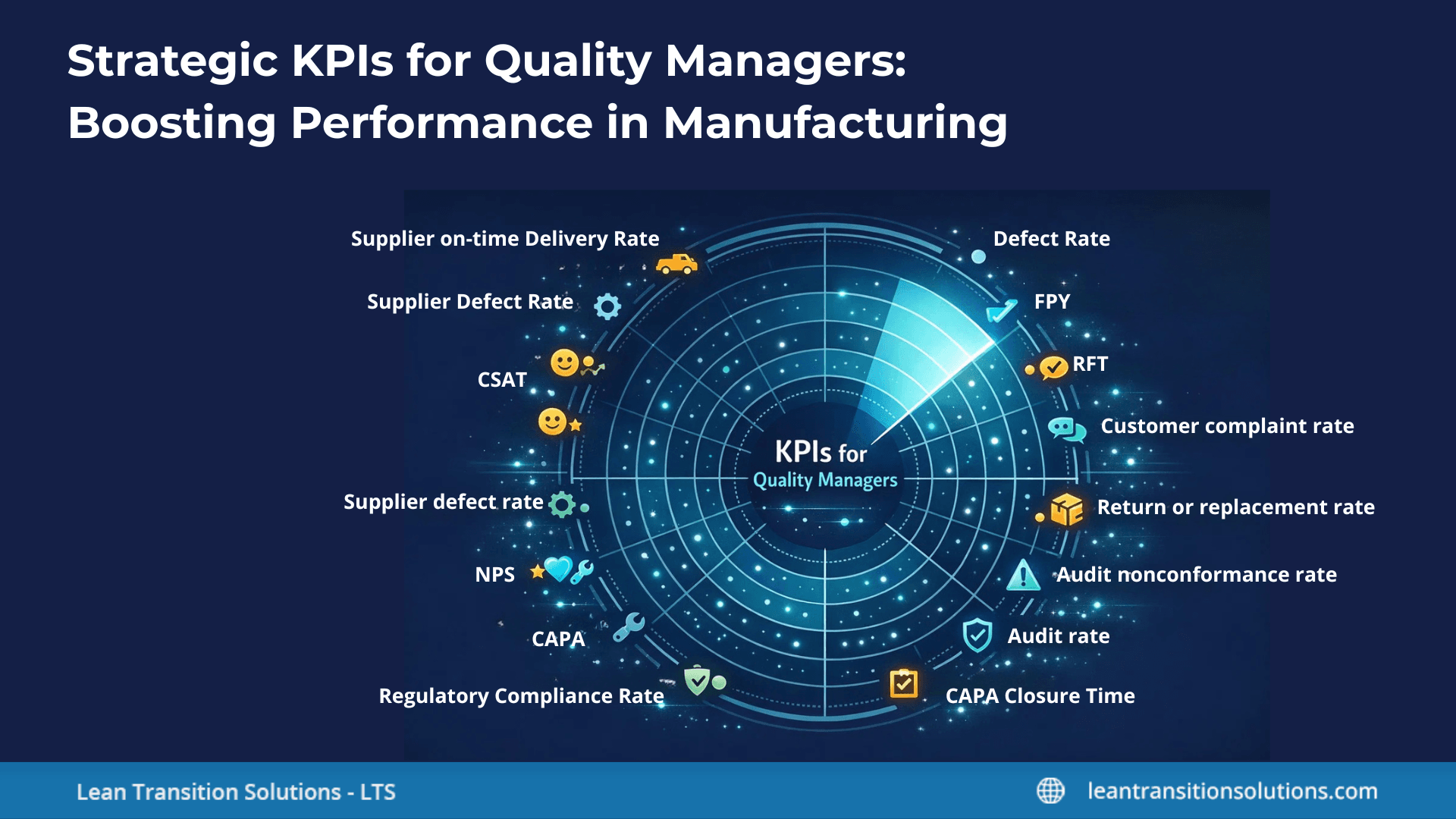

The most relevant KPIs include defect rate, first pass yield, customer complaint rate, audit nonconformance rate, CAPA closure time, and regulatory compliance rate. These help track product quality, operational efficiency, and customer satisfaction.

2. How often should quality managers review their KPIs?

KPIs should be reviewed regularly – daily for operational metrics like defect rate, weekly for tactical indicators such as CAPA progress, and monthly or quarterly for strategic KPIs like customer satisfaction and compliance rates.

3. Can KPIs vary between industries or departments?

Yes, KPIs should be customised to the specific needs of your organisation and industry. For example, RFT maybe critical in pharmaceuticals but less relevant in electronics. Always choose KPIs that reflect your company’s unique goals and challenges.

4. What makes a KPI effective for quality management?

An effective KPI is measurable, actionable, relevant to business goals, and time bound. It should offer clear insights that support decision-making and continuous improvement.

5. Why is it important to revise existing KPIs?

As your organisation evolves, some KPIs may become outdated or less important. Regularly reviewing and updating KPIs make sure they continue to reflect current objectives and drive meaningful improvements.

6. How can digital tools help in tracking quality KPIs?

Platforms like LTS Data Point provide real-time dashboards, automated data capture, and visual scorecards that simplify KPI tracking, minimise manual effort, and support faster, data-driven decisions.