What is PDCA cycle? Plan-Do-Check-Act board use explained

August 11, 2025

Your team fixed that bottleneck—until it showed up again.

You ran another root cause analysis—only to discover the same issue was “resolved” six months ago.

Your reports are full of actions taken, but performance still dips without warning.

Ever feel like your team is solving the same problems over and over-caught in a business loop of uncertainty with no clear way out?

Why?

This is the hidden cost of “almost fixed” problems—quick fixes that treat symptoms, not systems. That’s why high-performing companies don’t just act. They plan, do, check, act at every single step in business intelligence.

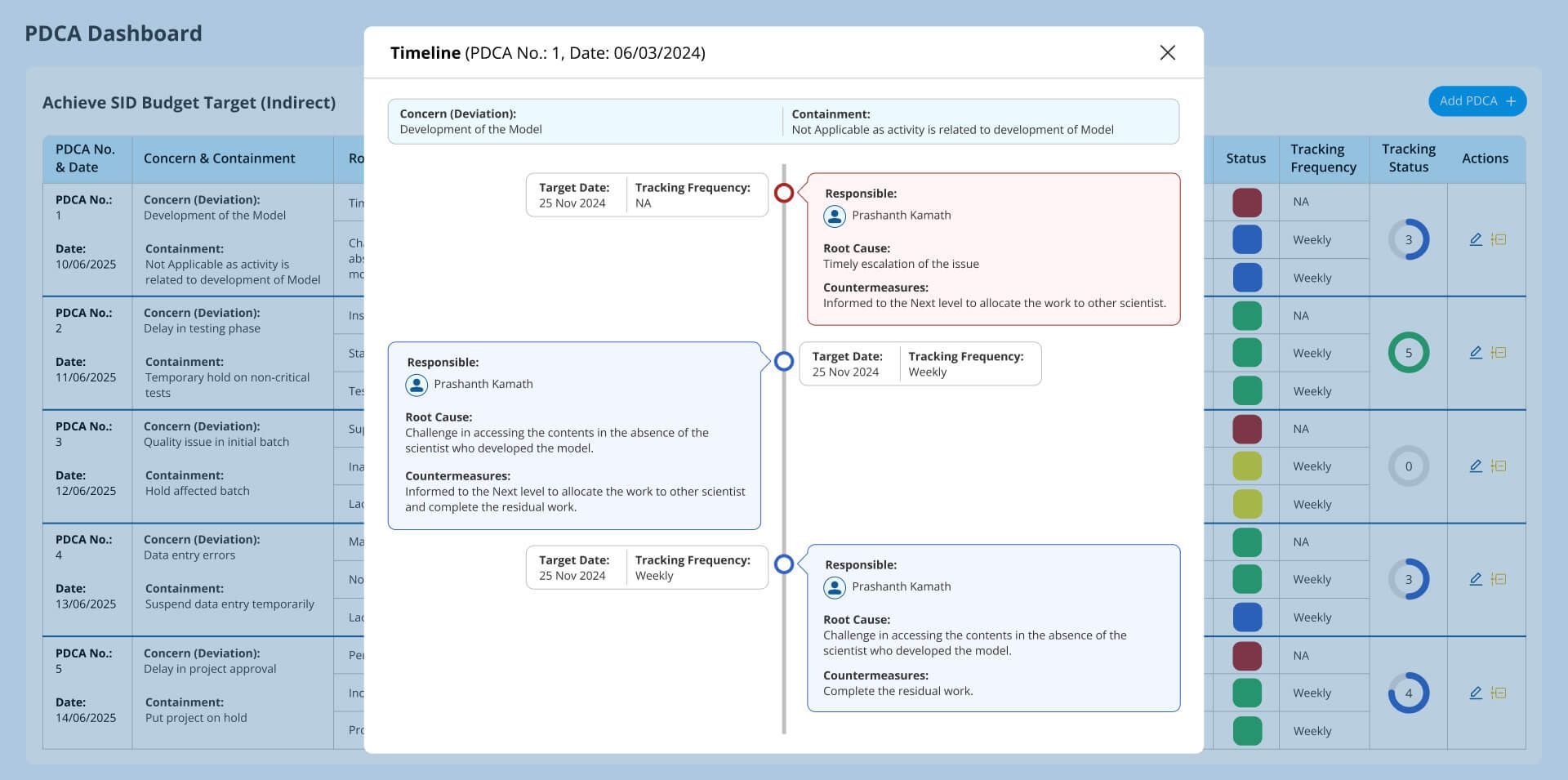

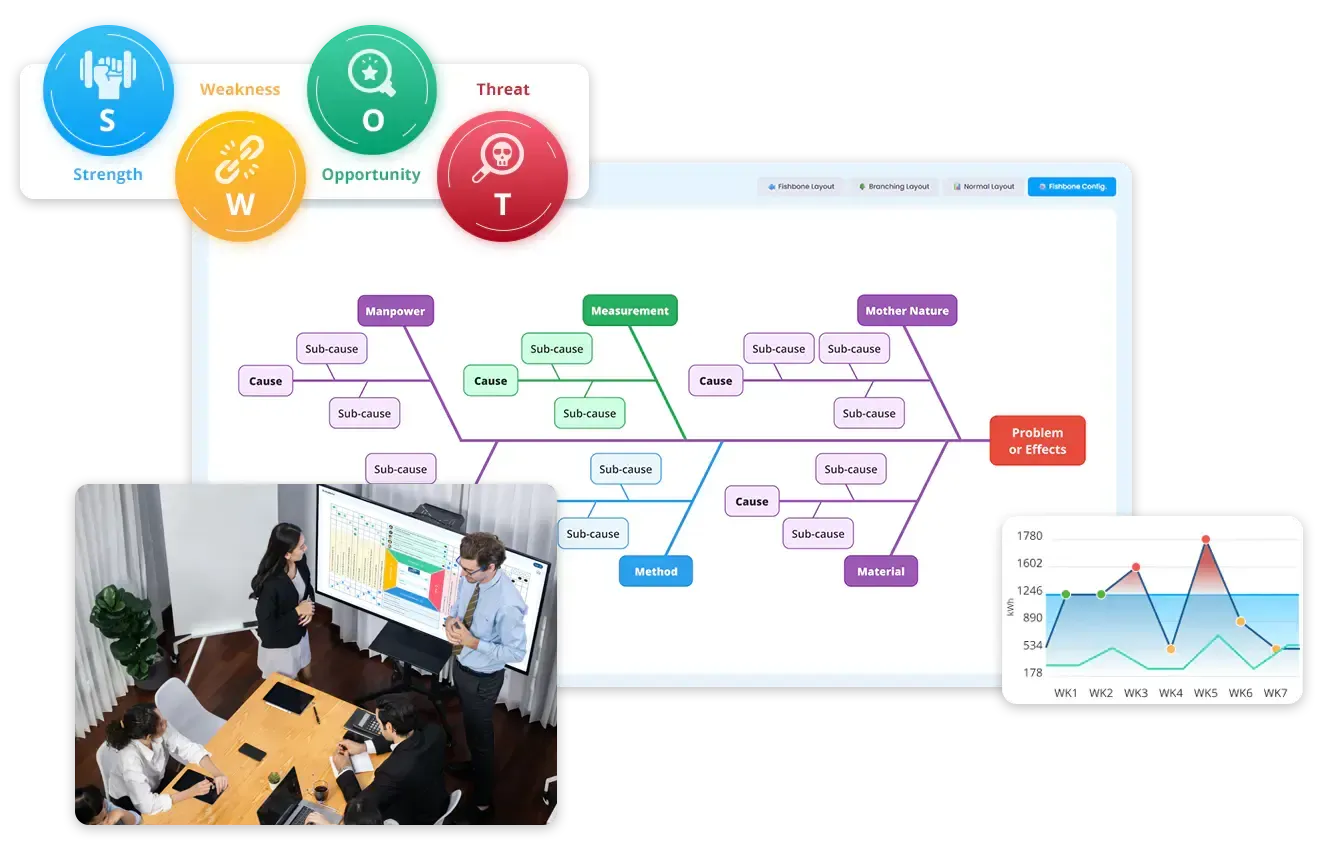

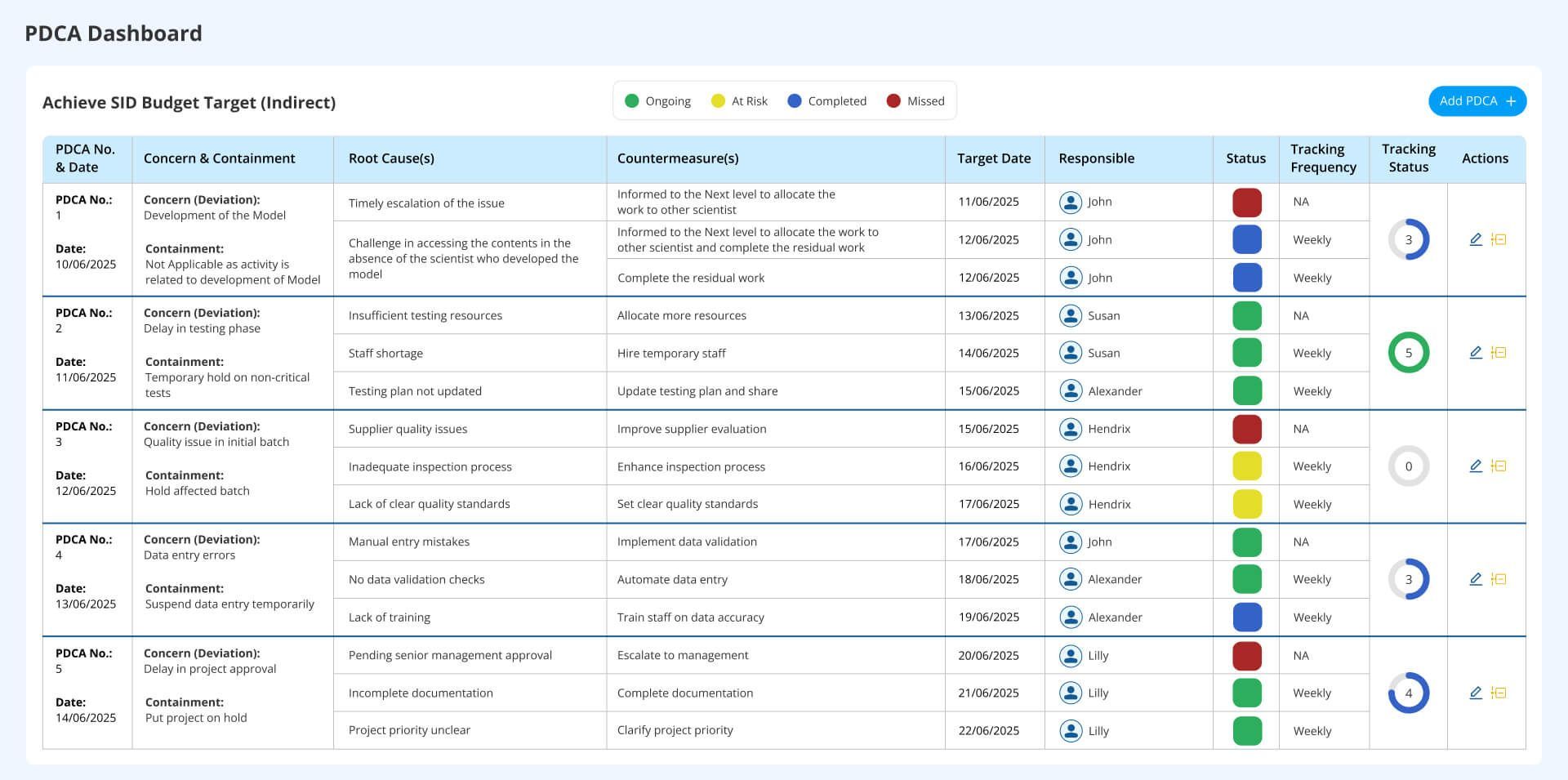

That’s where the Plan-Do-Check-Act comes in. PDCA cycle also commonly known as the Deming Cycle or Shewhart Cycle- it’s not just a methodology; it’s a scientific, iterative technique to solve problems, improve quality, and enhance business processes.

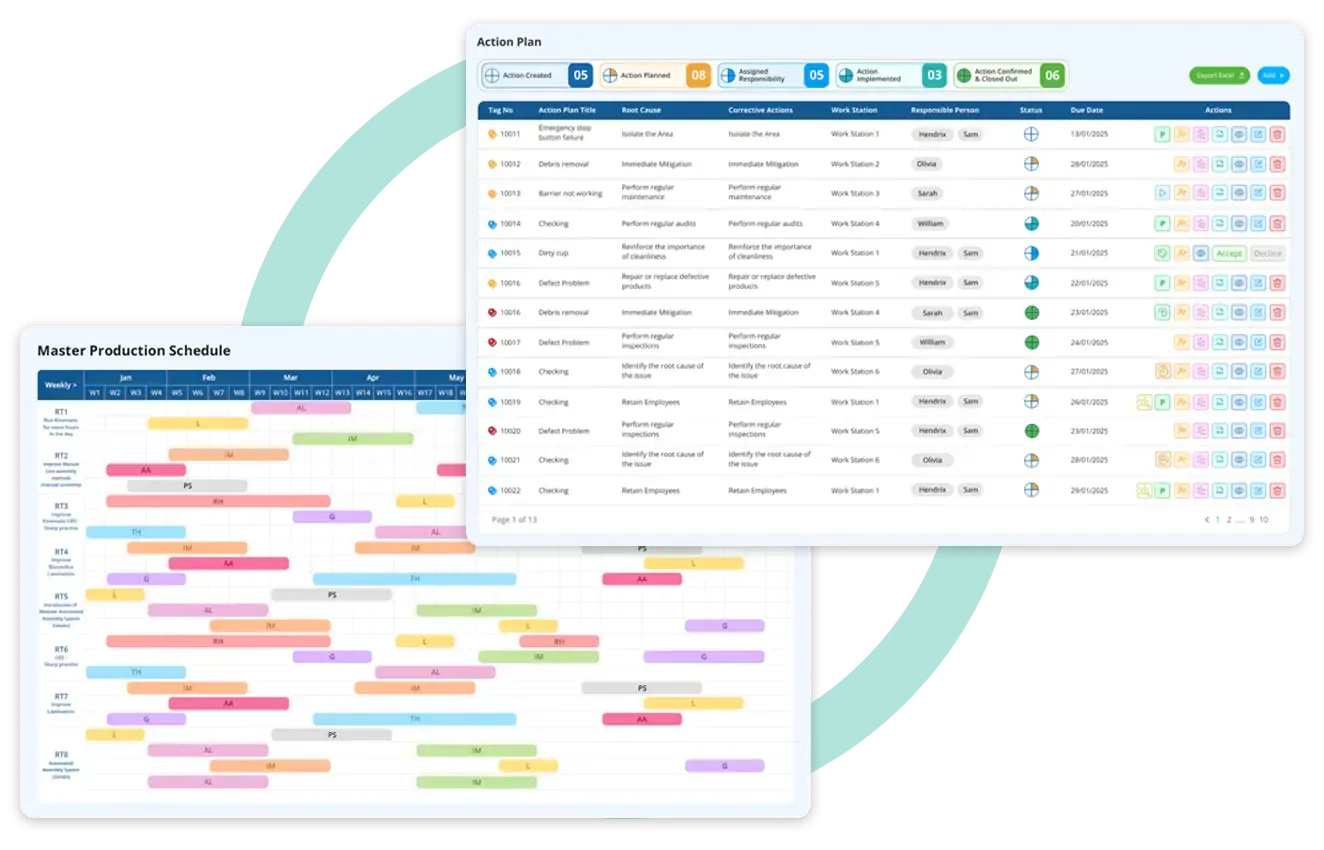

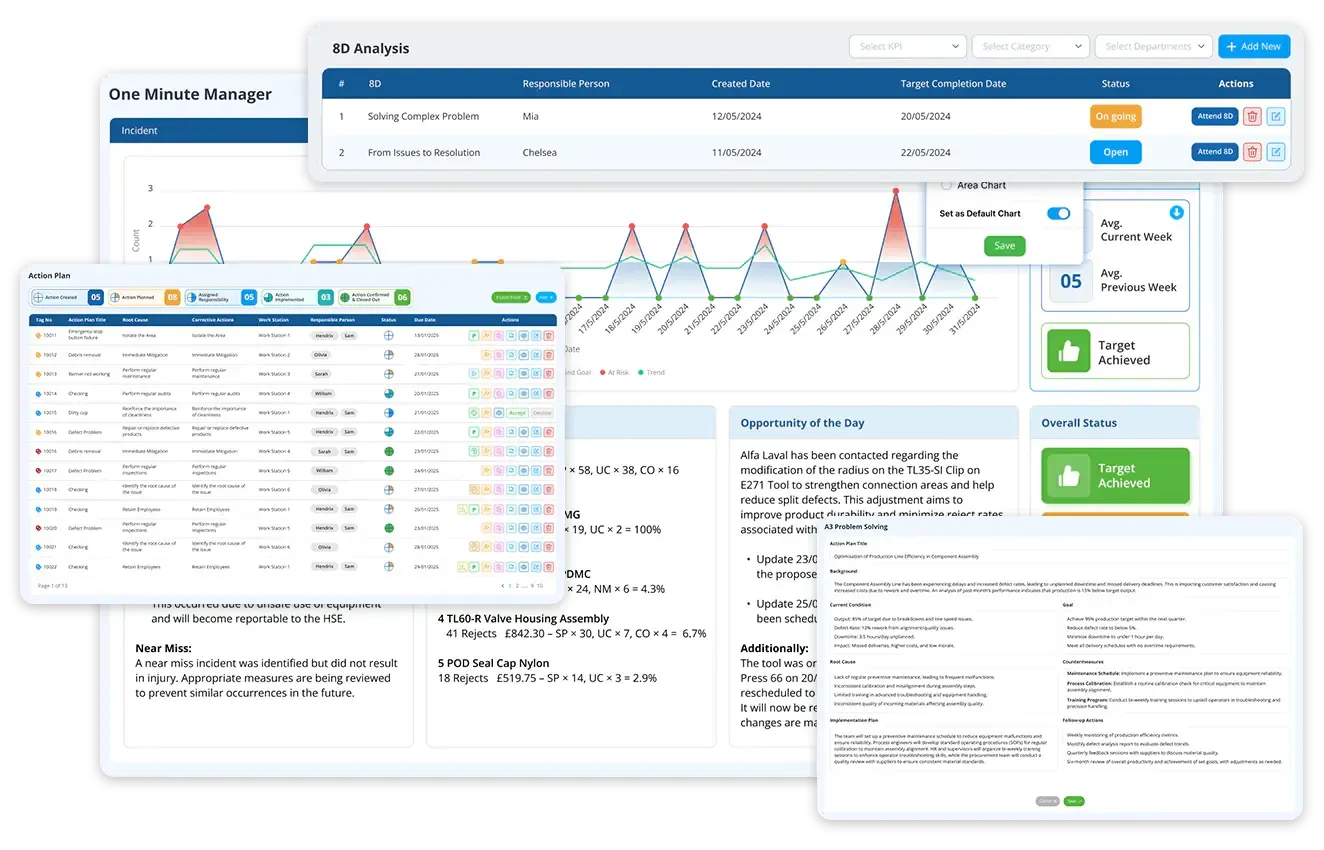

In this blog, we’ll break down the PDCA Cycle, show how to implement it effectively with LTS Data Point Balanced Scorecard, and explain why it’s essential for building a culture of strategic, continuous improvement. This blog will be your complete blueprint for PDCA understanding as a business survival strategy.

History of PDCA cycle: Journey from traditional methods to digital boards

Let's go back to early 20th century

The PDCA Cycle has its origins in 1920s and introduced by Walter A. Shewhart