FAQs

1. What is the best way to manage daily shop-floor operations?

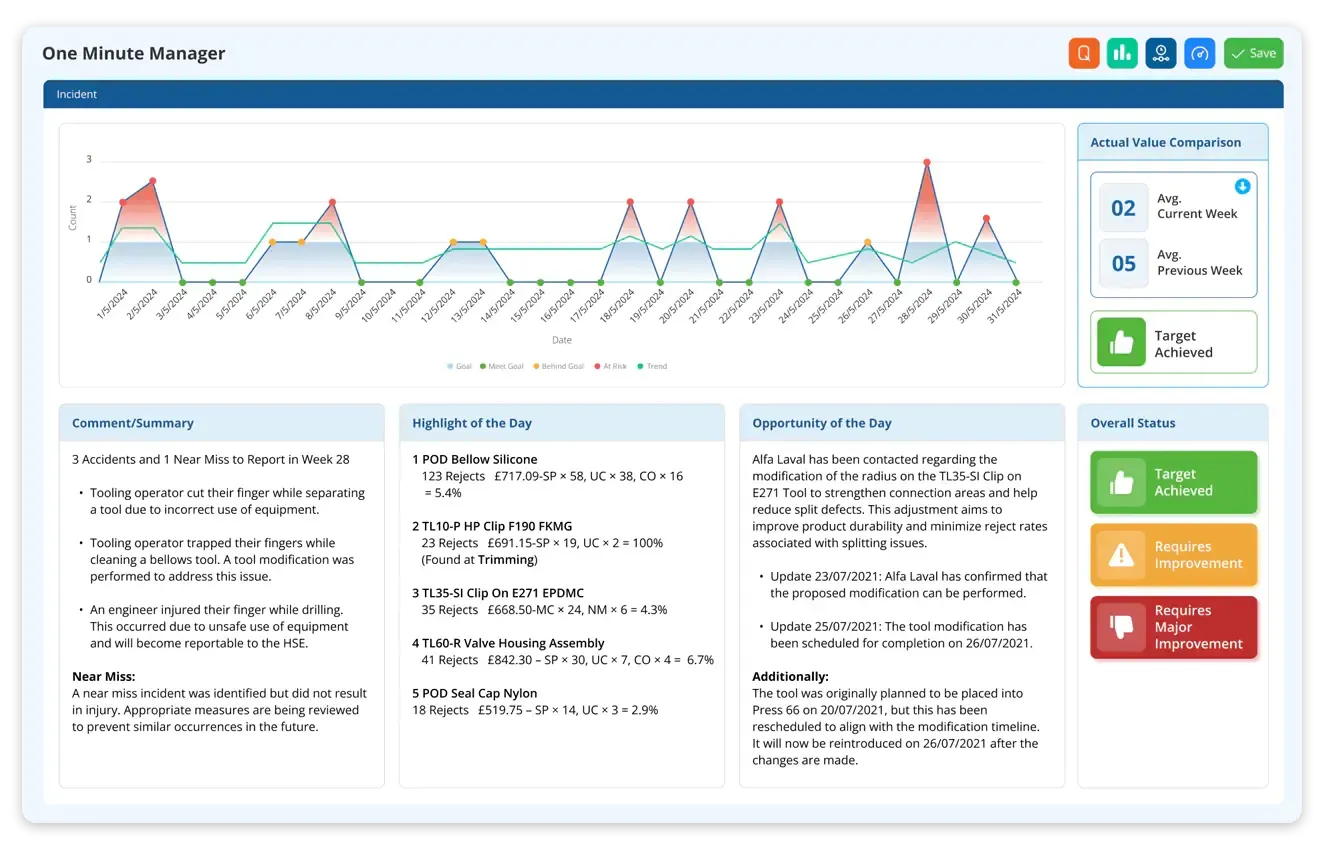

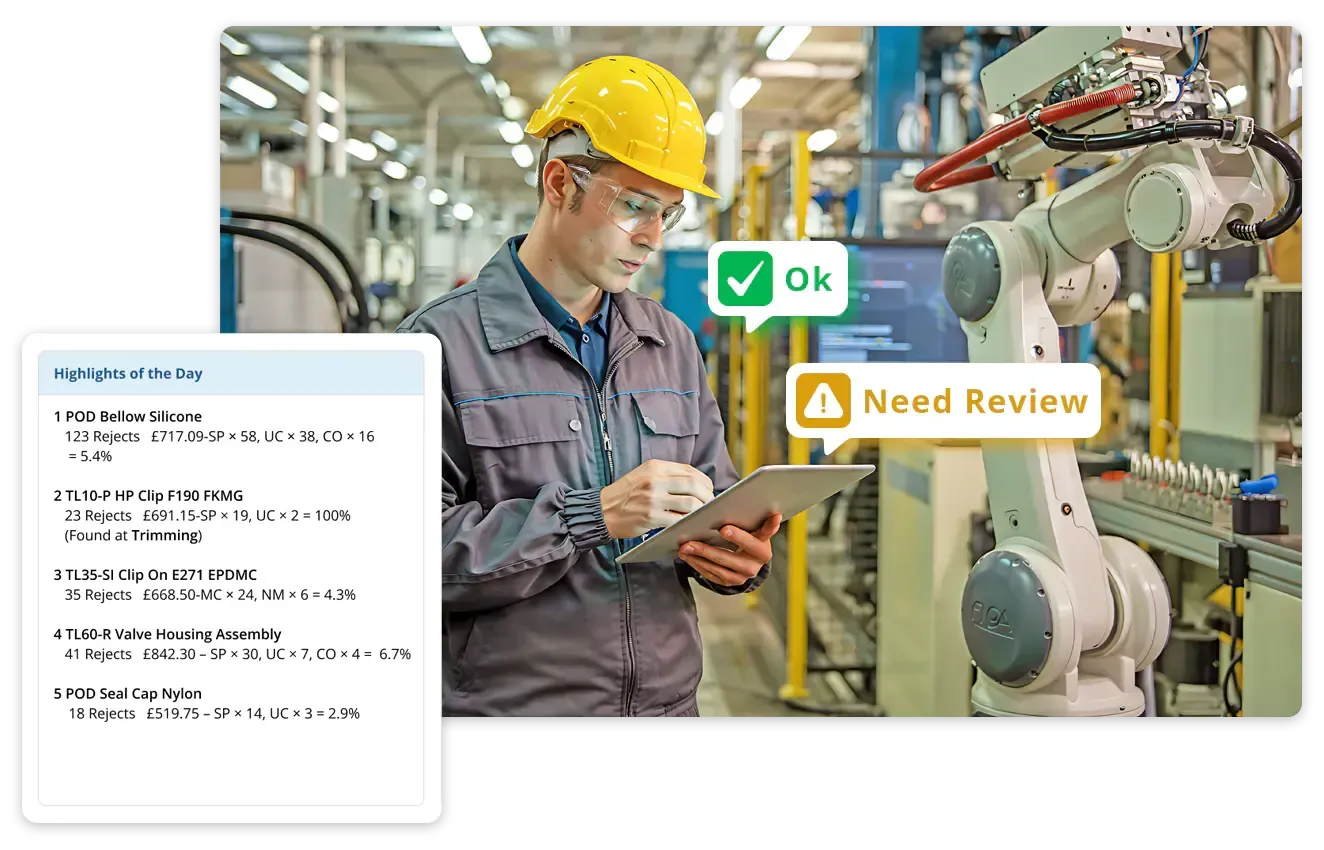

The most effective method is to run digital SQCDP boards, structured daily huddles, and tiered reviews supported by real-time data.

A platform like LTS Data Point helps standardise these routines across shifts and plants.

2. What are manufacturing operations manager challenges?

Manufacturing operations managers face challenges such as disconnected KPIs, manual reporting, delayed insights, inconsistent shift handovers, siloed data across MES/ERP/Excel, unstructured daily meetings, poor cross-functional alignment, slow root-cause analysis, and the continuous pressure to improve productivity, quality, and delivery with limited real-time visibility.

3. Why is an all-in-one Operational Excellence software essential for modern manufacturing?

Modern manufacturing needs more than dashboards — it needs a central platform that aligns KPIs, connects daily routines, supports SQCDP, drives PDCA, tracks actions, unifies data, and creates real-time visibility across plants and teams. Operational Excellence software eliminates manual work, speeds decisions, and ensures every activity aligns with organisational goals.

4. Why is LTS Data Point called the best manufacturing software for decision-makers?

Because Data Point gives decision-makers complete operational visibility: real-time KPIs, SQCDP dashboards, PDCA workflows, Hoshin Kanri alignment, cross-site comparison, and seamless integration with MES/ERP. Leaders can see performance, identify issues faster, and make confident decisions from a single platform — no switching tools or waiting for reports.

5. What are the solutions for manufacturing operations manager’s challenges?

Operations managers need solutions such as:

- Real-time KPI dashboards

- Digital huddle boards (Tier 1–3)

- SQCDP visual management

- PDCA, CAPA, and root-cause tools

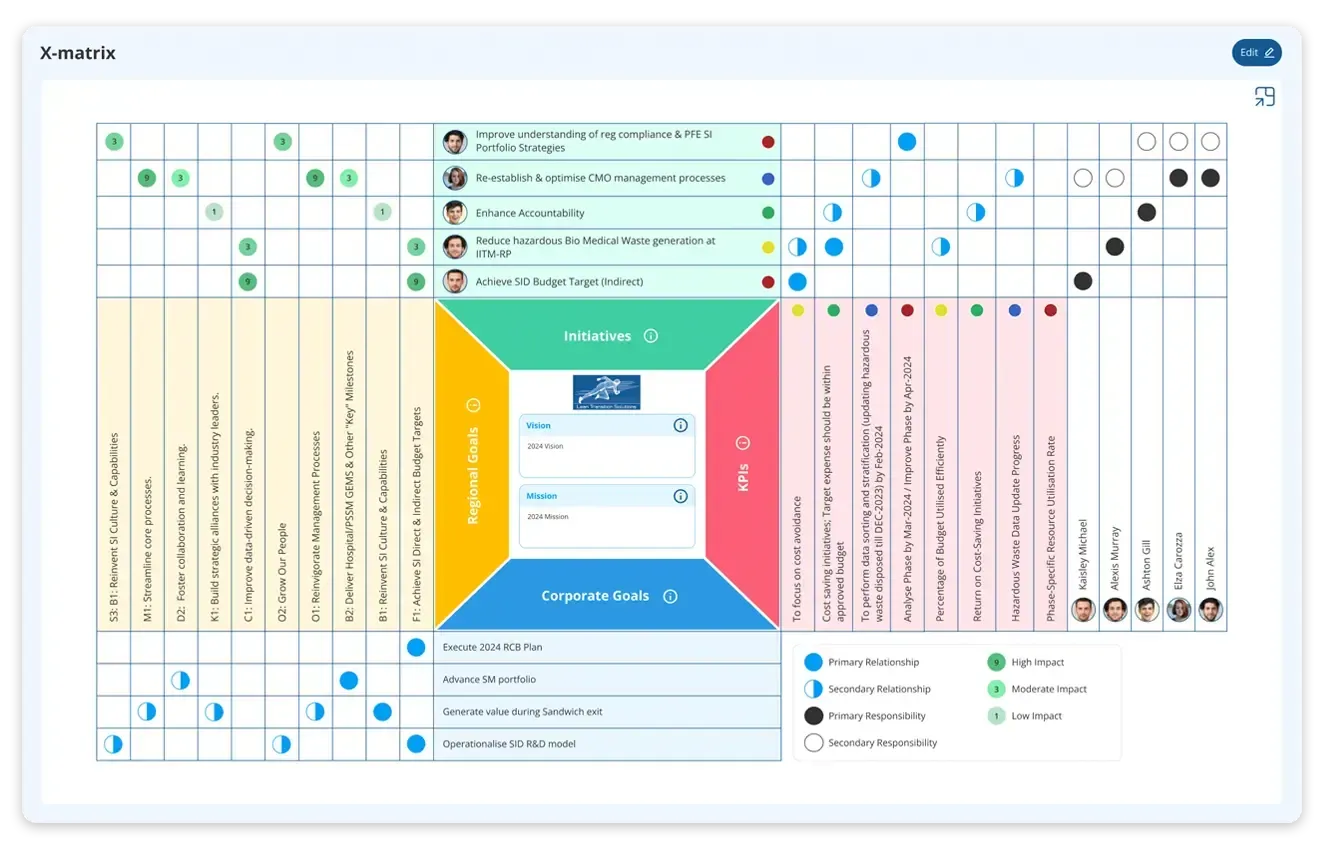

- Hoshin Kanri for strategy alignment

- Cross-plant performance comparison

- Automated reporting

- Seamless MES/ERP integration

Platforms like LTS Data Point unify all of this in one system.

6. How to get more visibility in manufacturing operations?

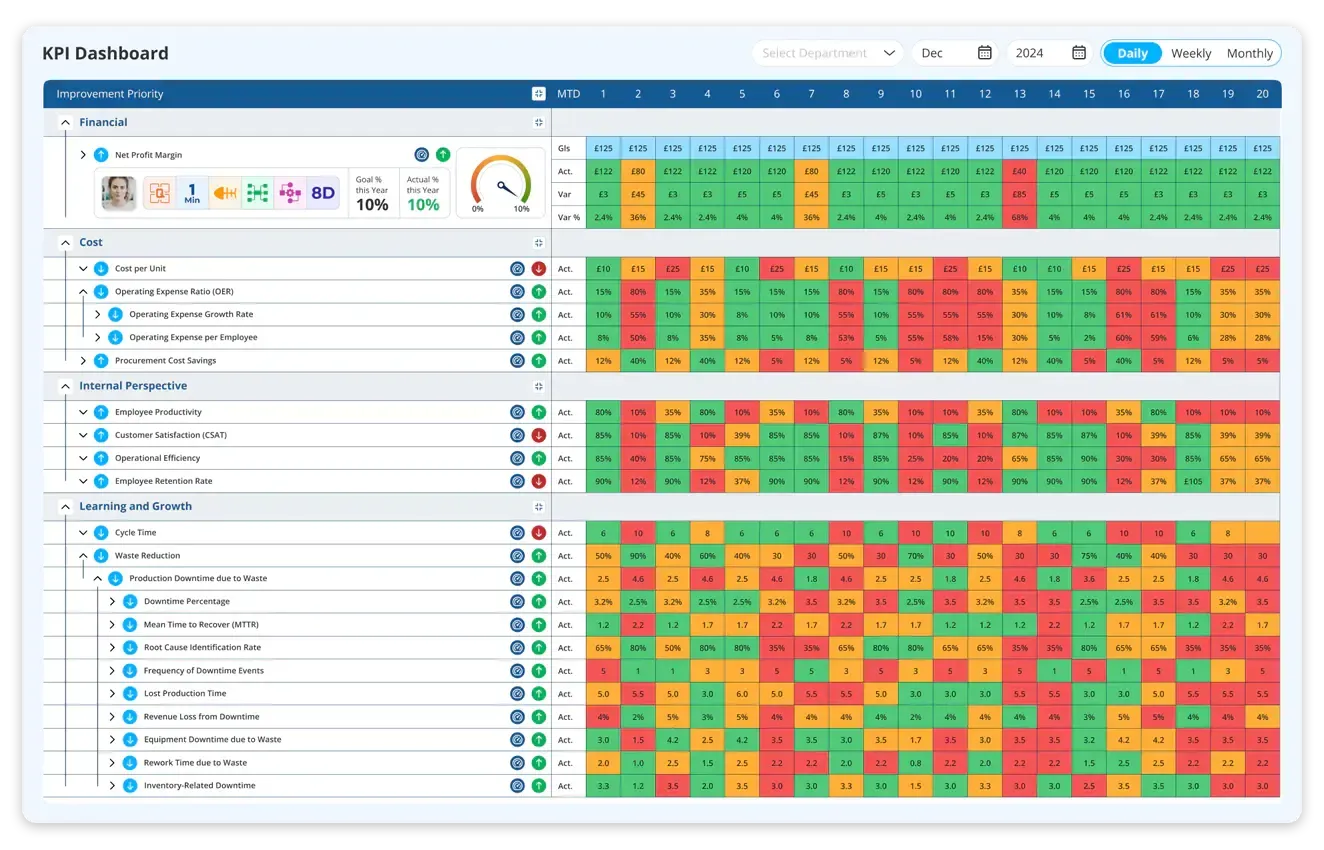

Visibility increases when data from MES, ERP, quality, maintenance, and shop-floor systems are brought into one connected visual platform. Real-time dashboards, scorecards, bowler charts, and deviation alerts help managers see performance clearly and act faster — this is exactly what LTS Data Point enables.

7. What KPIs should an operations manager track?

Key KPIs include:

- OEE (Overall Equipment Effectiveness)

- Downtime & MTTR/MTBF

- Production output & cycle time

- Defect rate & first-pass yield

- On-time delivery

- Cost of poor quality (COPQ)

- Safety incidents

- Attendance & workforce utilization

- Energy consumption

8. What is Manufacturing Operations Management (MOM) software?

MOM software covers planning, execution, and control of production processes.

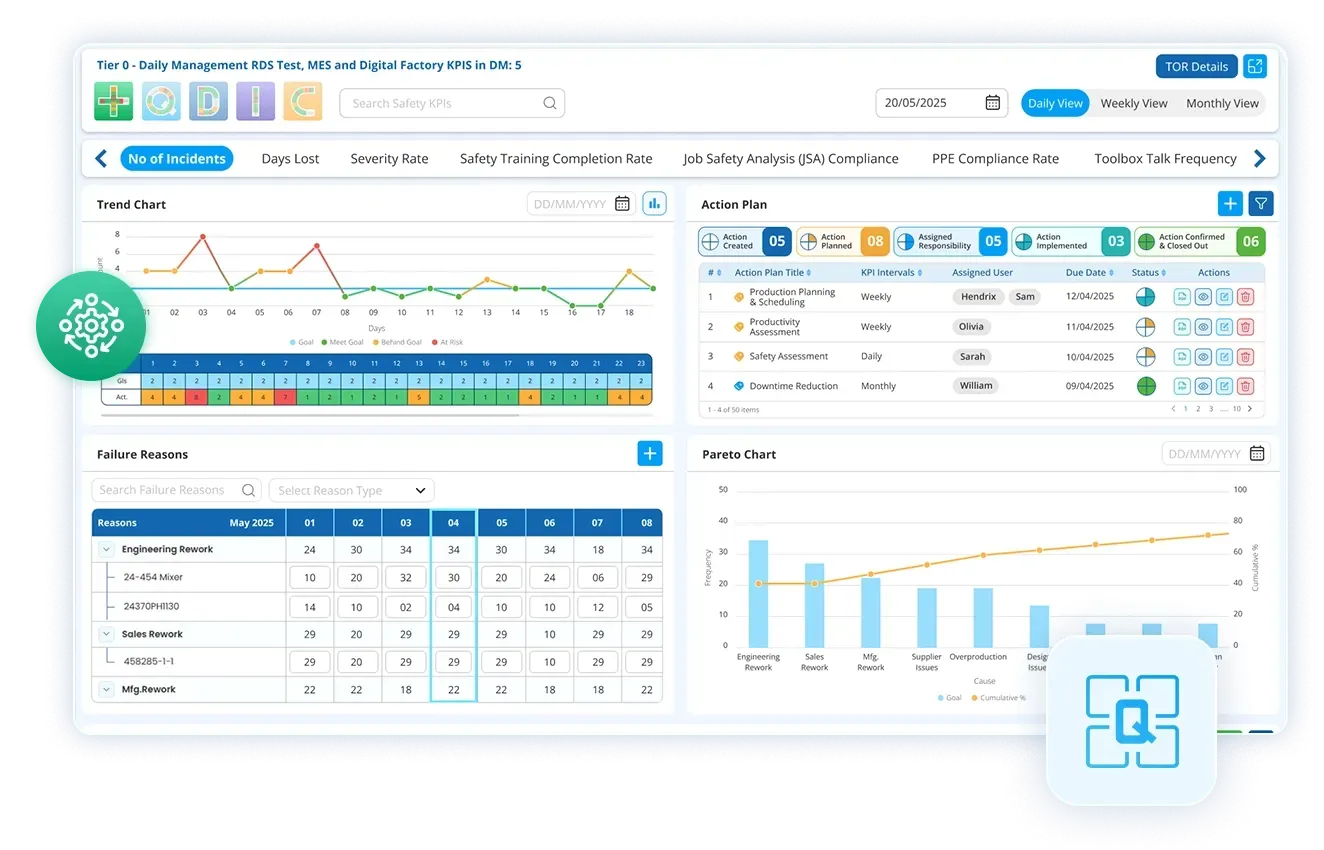

9. How is LTS Data Point different from a MOM software?

MOM software manages execution — work orders, production tracking, routing, WIP, instructions, scheduling.

LTS Data Point manages performance — KPIs, SQCDP, PDCA, huddles, strategy alignment, RCA, continuous improvement.

In simple terms:

MOM runs production; Data Point runs performance.