What is Lean Daily Management (LDM)?

A Lean Daily Management System (LDM) is a structured routine that enables teams to manage operations on a daily basis focused on lean principles. It’s a set of practices, tools, and routines that keep everyone aligned, focused, and clear on how their actions contribute to wider goals.

Why does Daily work management matter?

Many organisations, especially in manufacturing, struggle to keep things on track day to day. Teams often work hard, but goals still slip. Deadlines are missed, quality varies, and problems keep repeating.

Without a Daily management system, companies often deal with:

- Unclear priorities

- Delays in fixing problems

- Disconnected teams

- Repeated mistakes

- Leaders stuck in fire-fighting mode

So, what is a Daily management system?

A well-structured DMS reduces all of the silos in your process management. It provides a steady routine for how work is reviewed, how issues are handled, and how performance is discussed- every day, not just during monthly meetings or after something has gone wrong.

Benefits of Daily management system in work management

A DMS is a structured way of running your daily work. It helps frontline teams and managers keep things under control, spot issues early, and take the right action fast. It brings clarity, consistency, and ownership to everyday tasks - making sure the right work gets done, in the right way, at the right time.

- Enabling daily performance management: By tracking Key performance Indicators (KPIs) and metrics in real-time, a DMS allows teams to measure performance against daily goals and take corrective actions immediately.

- Creating a standard operating rhythm: Structured meetings like daily huddles and tiered reviews give teams a consistent way to communicate, escalate issues, and share progress.

- Improving operational control: A DMS reduces variation and uncertainty by ensuring standard work is followed, tasks are completed on time, and deviations are addressed promptly.

- Supporting lean daily management tools: Visual boards, escalation workflows, and Gemba Walks are often part of a DMS, making operations more transparent and improvement focused.

- Driving engagement and problem-solving: When teams are involved in reviewing performance and solving problems every day, it builds ownership and a proactive mindset.

- Linking daily work to strategic goals: A DMS ensures that even the smallest daily task contributes to broader organisational objectives, helping bridge the gap between planning and execution.

Daily management system vs. Lean daily management system: A side-by-side comparison

Are daily management and Lean daily management the same? It’s a common question—and the short answer is not quite.

Why should you go for the lean daily management system for efficient management? Here is the answer:

While Daily Management System (DMS) and Lean Daily Management System (LDMS) are often used interchangeably, there's a subtle but important distinction. Both aim to keep daily operations on track. But LDMS goes a step further. It’s grounded in Lean thinking, meaning it doesn't just manage today’s tasks; it builds a culture of continuous improvement, problem-solving, and team empowerment. So, while every LDMS is a DMS, not every DMS embraces the Lean mindset that drives long-term growth and efficiency.

Let us clearly understand the difference between a DMS and a LDMS at a glance.

Quick takeaway:

If your goal is just to manage daily performance, a basic DMS may suffice.

If your goal is to grow, improve, and empower teams, then a Lean Daily Management System is the smarter choice.

Now you may be wondering: What makes Lean Daily Management so effective? To truly leverage the power of Lean, it’s essential to understand the key elements that drive this system forward.

Key elements of a Daily management system in Lean

A well-structured Daily management software in lean is pivotal for organisations aiming to enhance operational efficiency, foster continuous improvement, and align daily activities with strategic goals.

Below, we explore the fundamental components that constitute an effective DMS.

To make these components easier to grasp, let’s breakdown and categorise the core elements of Lean Daily Management into Principles, Tools, and Operational Processes.

1. Core principles of Daily Work Management

These principles are the fundamental beliefs that guide Lean practices and decision-making in work management. These foundational principles underpin the successful implementation and sustainability of a DMS:

- Leader Standard Work (LSW): Establishes routine tasks and responsibilities for leaders to ensure consistent oversight and support for frontline teams.

- Daily accountability: Promotes ownership and responsibility at all organisational levels, ensuring that tasks are completed, and objectives are met consistently.

- Communication cascade: This ensures that information flows smoothly up and down the organisation, keeping everyone aligned and responsive.

- Visual management and transparency: Utilises visual tools such as boards and dashboards to display key performance indicators (KPIs), making performance data transparent and accessible.

- Continuous improvement (Kaizen): Encourages regular, incremental enhancements to processes, fostering a culture of ongoing development and efficiency.

Common challenges in Lean daily management and how to overcome them

Implementing a Lean Daily Management System is powerful, but it comes with hurdles, especially during the early stages. Here's how to handle them effectively:

1.Lack of leadership buy-in

Solution: Educate leaders on the long-term benefits of LDM. Involve them in reviews, walkthroughs, and decision-making to build ownership.

2. Inconsistent daily routines

Solution: Standardise huddles, update times, and escalation processes. Use visual reminders and assign clear responsibilities.

3. Poor data accuracy or timeliness

Solution: Shift to digital tools that auto collect and visualise real-time data. Train teams in data input importance.

4. Overcomplicated boards or KPIs

Solution: Keep visual boards simple and relevant. Limit KPIs to those that are actionable and meaningful to the team.

5. Low team engagement

Solution: Let teams own their metrics and improvement actions. Recognise small wins and foster an open feedback culture.

6. No clear escalation path

Solution: Set up tiered meetings and visual triggers (e.g., red zones or alert markers) to flag unresolved issues clearly.

7. Resistance to behavioural change

Solution: Involve teams in co-creating standards and visuals. Reinforce that DMS is about support and shared ownership

8. Lack of follow-through on actions

Solution: Implement short-interval management tools or action-tracking dashboards. Assign owners and deadlines for all raised actions and review progress.

Lean Daily management system example in manufacturing

Below is a practical example from a manufacturing setting, showing how simple daily practices and visual tools can drive real improvements in productivity, problem-solving, and team engagement.

Scenario: A car parts manufacturer is facing delays in its assembly line due to frequent machine breakdowns and unclear shift communication.

How Lean daily management is applied:

- At the start of each shift, team leaders conduct 10-minute huddle meetings to review safety alerts, production targets, and any issues from the previous shift.

- A visual management board displays key metrics such as output, downtime, defect rates, and team attendance - updated in real time.

- Every two hours, supervisors check for abnormal conditions (e.g., missed targets) and take corrective action quickly with the help of structured short interval management.

- When a machine fails, the team logs it on a problem-solving method. Using a simple root cause analysis (e.g., 5 Whys), they identify and address the issue.

- If an issue isn’t resolved within a set time, it escalates to the next level in a structured, tiered meeting - ensuring fast response.

- The team reviews trends, recurring problems, and improvement opportunities through weekly review meetings linking them to larger process improvement efforts.

Result:

Breakdowns are reduced by 30%, and production targets are consistently met, thanks to daily visibility, quick decision-making, and team ownership.

Can a business really manage all this without error? Yes, but only with the right support. What’s needed is a digital tool that doesn’t just track one or two activities, but one that’s purpose-built for the full scope of Lean Daily Management. That’s exactly what

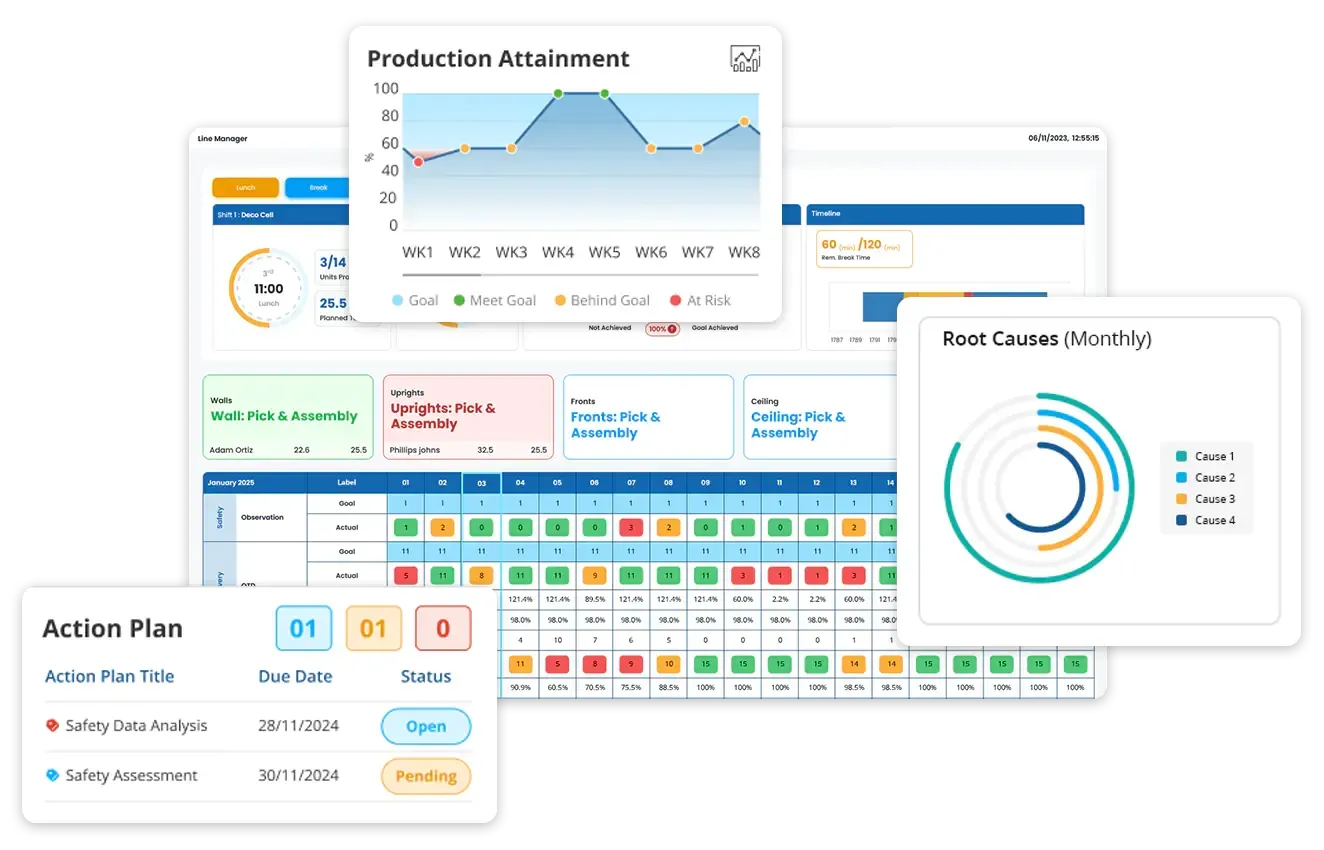

Data Point Balanced Scorecard is more than software; it’s a centralised platform designed to handle all the moving parts of daily management, from shop floor to strategy. With real-time, customised dashboards, escalation tracking, visual controls, and performance alignment, Data Point makes it possible to maintain structure, consistency, and continuous improvement- without chaos.

FAQs

1. How can Lean Daily Management help sustain continuous improvement?

Lean Daily Management keeps improvement efforts alive by creating a daily rhythm of monitoring, discussion, and action. It helps teams maintain focus on key metrics, identify small deviations early, and make timely decisions that prevent performance decline.

2. What are the essential elements of an effective Lean Daily Management system?

An effective system includes visual performance boards, clear KPIs, structured daily meetings, root cause tracking, and accountability frameworks. Together, these elements help teams stay aligned, communicate effectively, and act on improvement opportunities.

3. Why is Data Point the best software for Lean Daily Management?

Data Point is designed to digitalise every aspect of Lean Daily Management. It combines visual boards, KPI tracking, and action follow-ups in one platform, giving teams real-time visibility and control. Its intuitive design helps sustain Lean practices without the clutter of manual updates.

4. How does Data Point support team collaboration in Lean Daily Management?

Data Point enables cross-functional teams to collaborate seamlessly through shared dashboards, status updates, and alerts. By centralising information, it reduces communication gaps, supports quick decision-making, and ensures everyone is aligned on performance priorities.

5. How can organisations get started with Lean Daily Management?

Begin by defining measurable daily goals, assigning ownership, and setting up a visual management system to track progress. Start small—focus on one area, refine the process, and gradually expand across teams. Using a digital platform like Data Point can simplify this transition and ensure consistent execution.