How Visual Management System (VMS) helps you to become a proactive leader in the workplace?

September 2, 2025

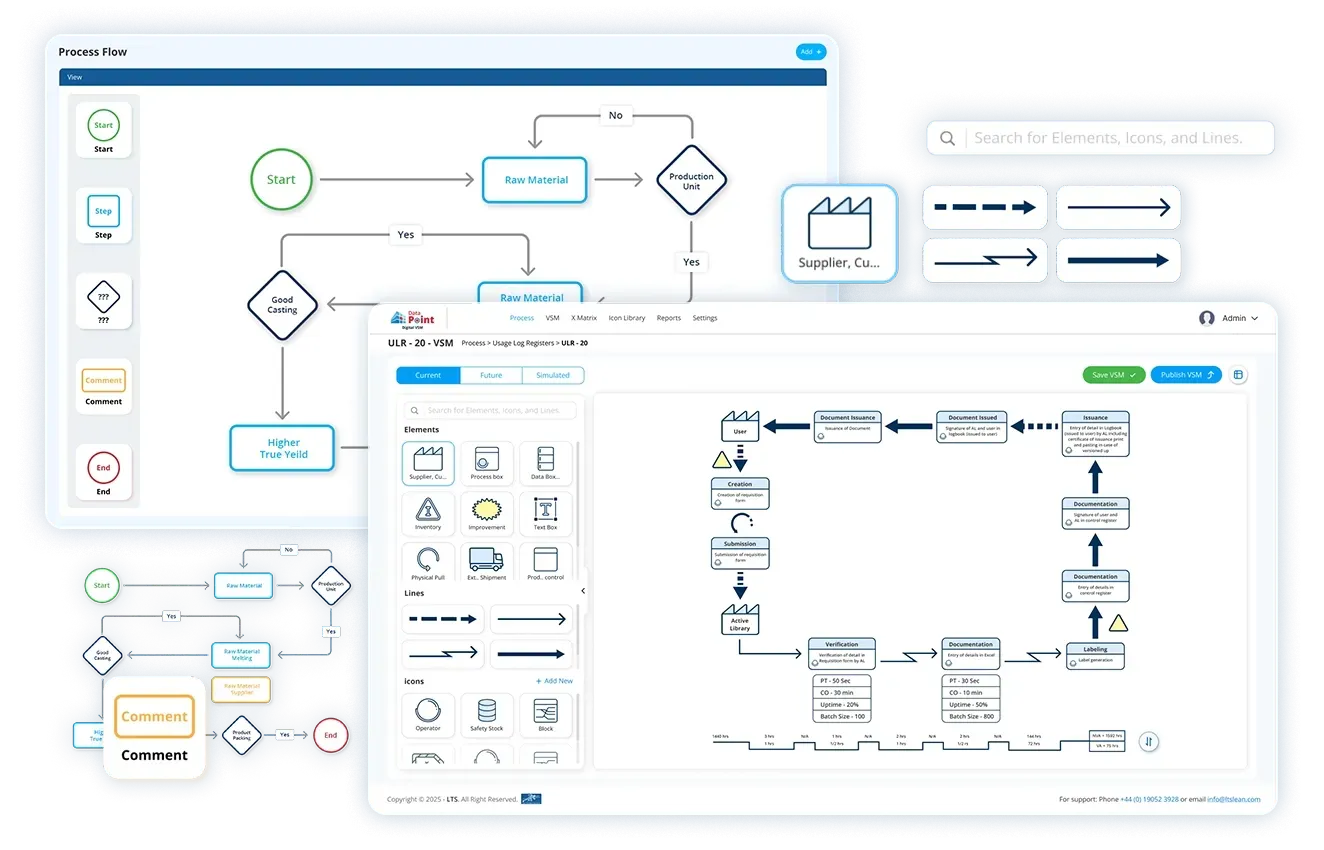

Traditional leadership often struggles with delays in decision-making, fragmented data, and blind spots that reduce efficiency. When leaders don’t have full visibility into operations, decisions are made late, opportunities are missed, and waste accumulates silently on the shop floor. This is where Visual Management Systems (VMS) come into play. Because a picture is worth a thousand words. Through this blog you will unlock smarter systems to sharpen your visual management and become a proactive leader who’s always one step ahead.

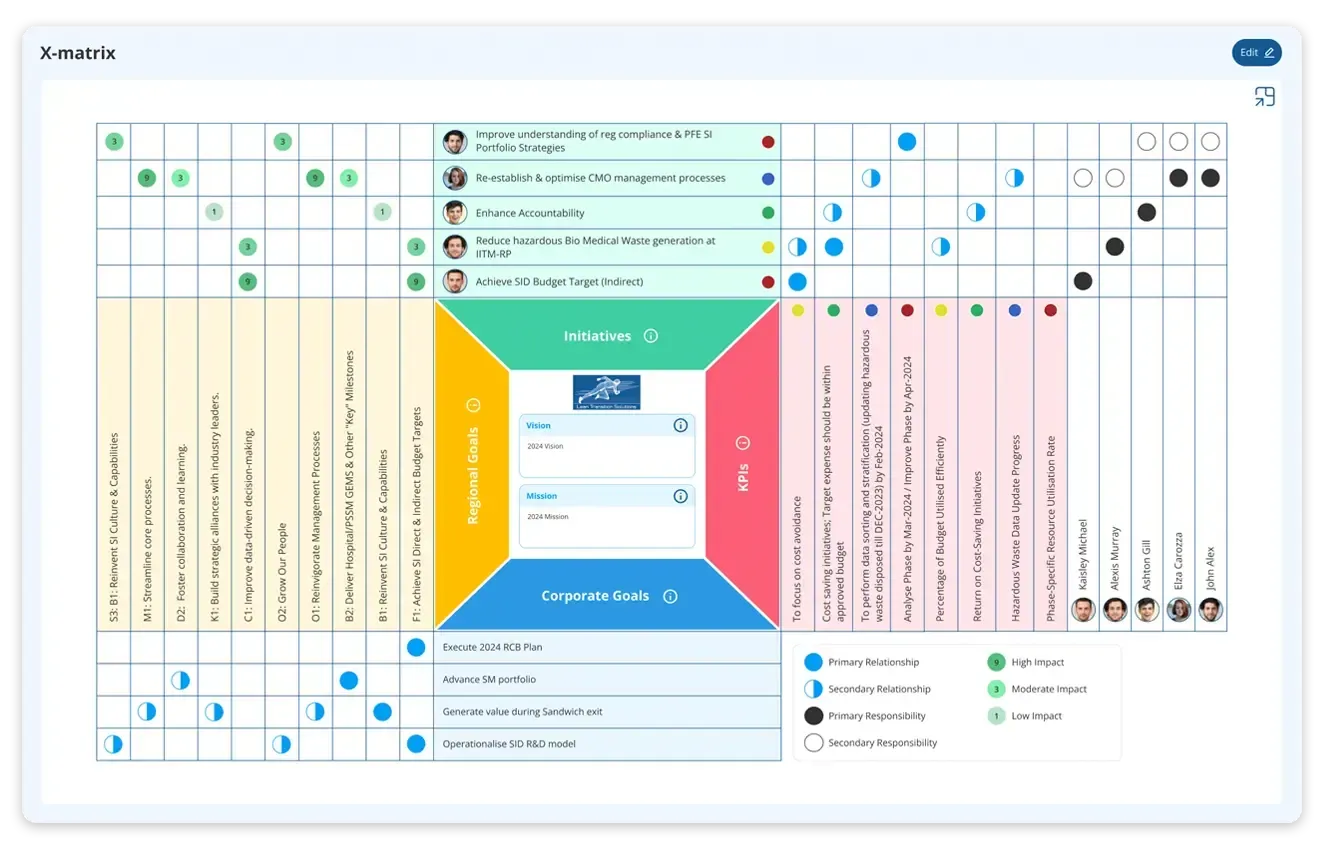

Power of Visual Management System (VMS): Shift from reactive to proactive leadership

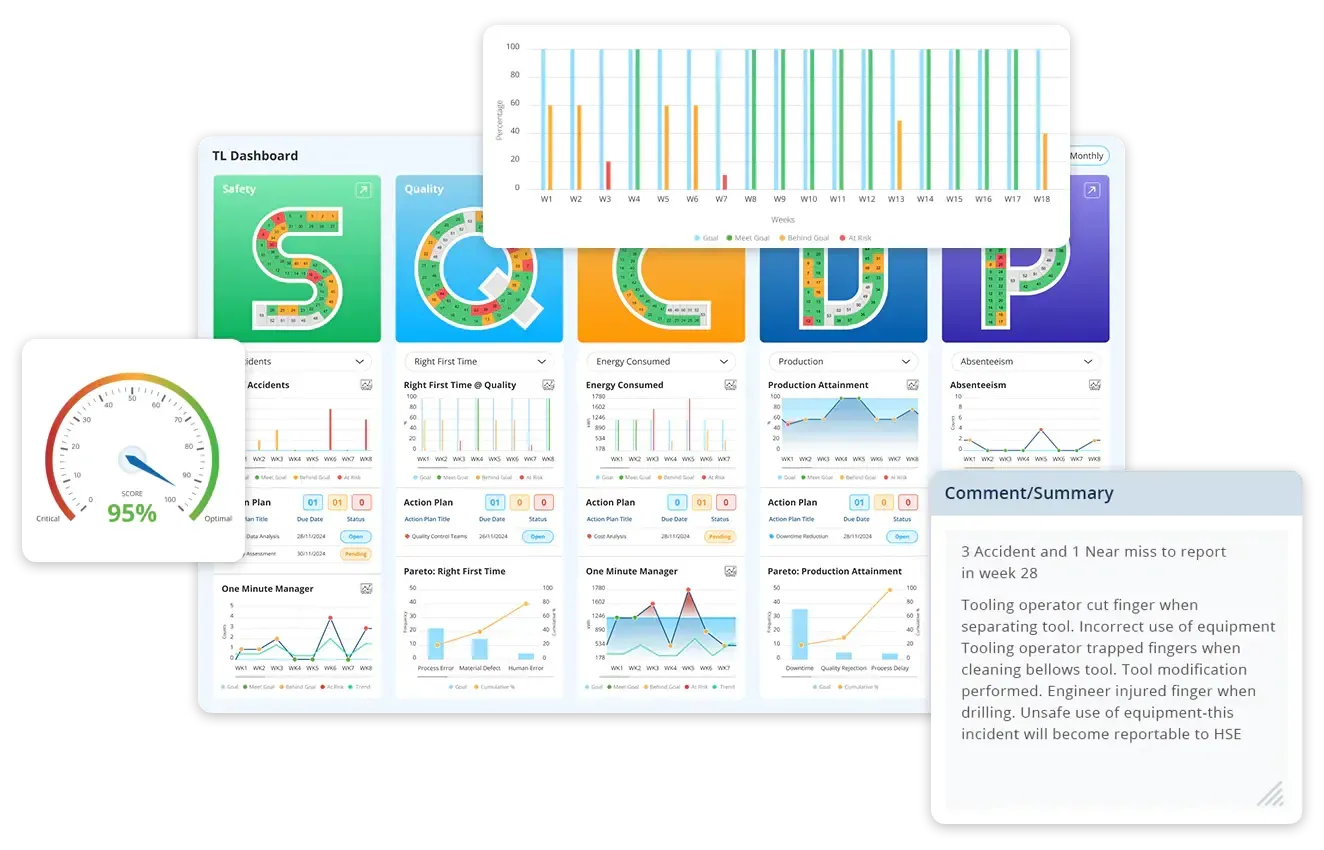

Visual Management is more than just a lean tool — it’s a leadership enabler. The power of visual management lies in its ability to make the invisible visible, allowing managers and executives to detect issues early, communicate expectations clearly, and drive accountability. For leaders striving for a culture of continuous improvement, visual management becomes a psychology-driven approach that improves focus, transparency, and trust within the workplace.

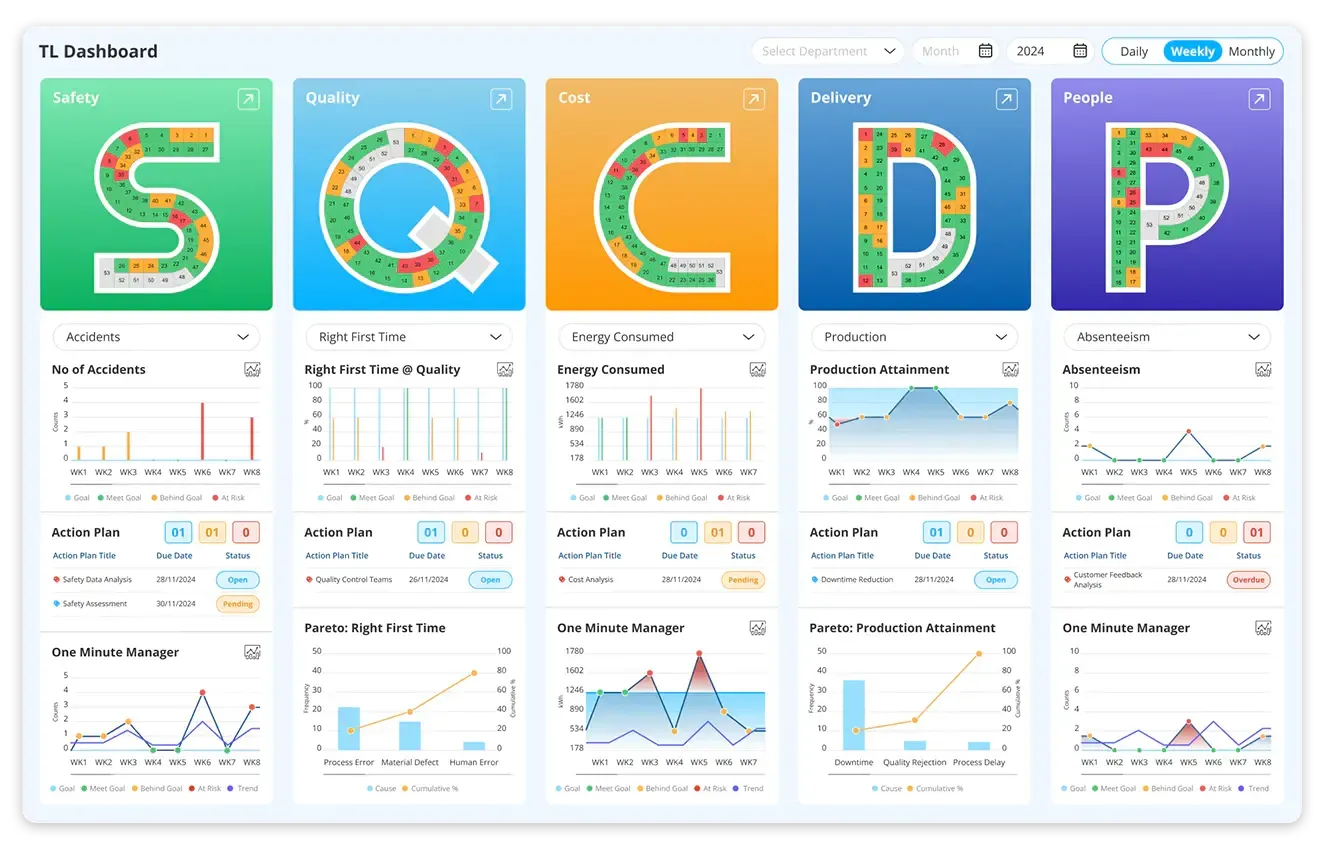

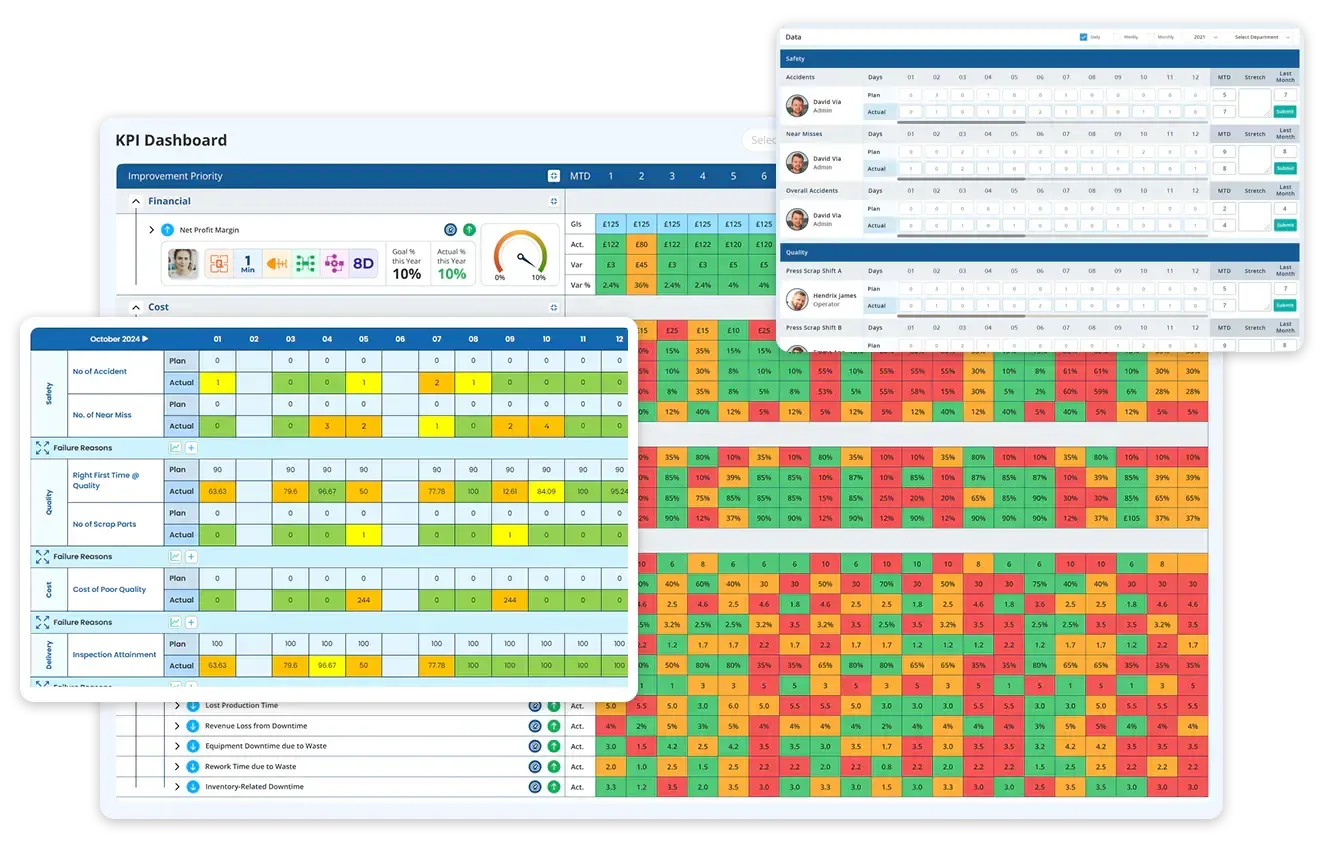

A VMS provides leaders with real-time insights, visual cues, and performance dashboards that transform complex data into actionable knowledge. It is a step beyond firefighting and becoming proactive leaders who align strategy, people, and processes.

This blog deals with how a visual management system helps leaders enhance visibility, why visibility fails, improve decision-making, streamline operations, and drive operational excellence.