5. Visuals not aligned with organisational goals

The challenge:

Visual boards sometimes focus on local issues without reflecting broader strategic objectives. This can create a disconnect between daily tasks and company goals, reducing alignment and effectiveness.

The solution:

Use a tiered visual management system. Tier 1 boards focus on local, operational KPIs; Tier 2 links departmental goals; Tier 3 aligns with strategic objectives. Ensure that visual tools help teams see how their efforts contribute to the bigger picture. Use goal cascades and KPI alignment frameworks like the balanced scorecard to maintain clarity.

6. Poorly designed visuals causing confusion

The challenge:

If a board is difficult to read—due to poor layout, inconsistent colours, or confusing symbols—then the message is lost. In worst cases, teams may misinterpret data or ignore the visuals altogether.

The solution:

Design visual tools with clarity in mind. Use clear labels, consistent colours, and standard symbols. Place critical information at eye level and in prominent positions. Avoid mixing data types without clear separation. Test new board designs with small groups before wider rollout,and make adjustments based on user feedback.

7. Outdated data leading to poor decisions

The challenge:

Visual management tools are only as good as the information they display. If boards are not updated regularly—or rely on data that is several hours or days old—teams may act on incorrect assumptions.

The solution: Create strict update routines, with assigned responsibilities and regular check-ins. Whenever possible, automate data collection and integrate it directly into visual boards. Use real-time tools for critical metrics like machine performance, quality issues, or delivery status. Establish review points throughout the day to verify accuracy.

8. Resistance to change from existing processes

The challenge:

Some teams are comfortable with their current methods and see new visual tools as unnecessary or burdensome. This resistance can stall or even reverse improvements.

The solution:

Introduce changes gradually. Start with pilot areas, demonstrate clear benefits, and let employees experience quick wins. Communicate why the changes are being made and how they support better outcomes. Provide hands-on training and create opportunities for feedback and adaptation. Make it clear that the goal is to simplify work, not add extra tasks.

The challenge:

Visual management is often seen as a production tool, leaving departments like maintenance, logistics, or quality without visibility or coordination.

The solution:

Extend visual practices to all functional areas. Maintenance can use visual schedules or breakdown trackers. Quality teams can maintain visible issue logs and improvement actions. HR can track training or engagement metrics. A cross-functional visual culture helps break silos and drives collaboration across the value stream.

10. Difficulty maintaining visual management over time

The challenge:

After initial implementation, boards often become neglected. Data becomes stale, updates are missed, and the system loses credibility. Without ongoing reinforcement, visual management fades into the background.

The solution:

Make visual boards part of everyday routines. Use them in daily huddles, weekly reviews, and problem-solving sessions. Assign board champions or area leaders to maintain them. Recognise teams that keep their boards updated and use the data effectively. Review visual systems monthly to assess relevance, accuracy, and user feedback.

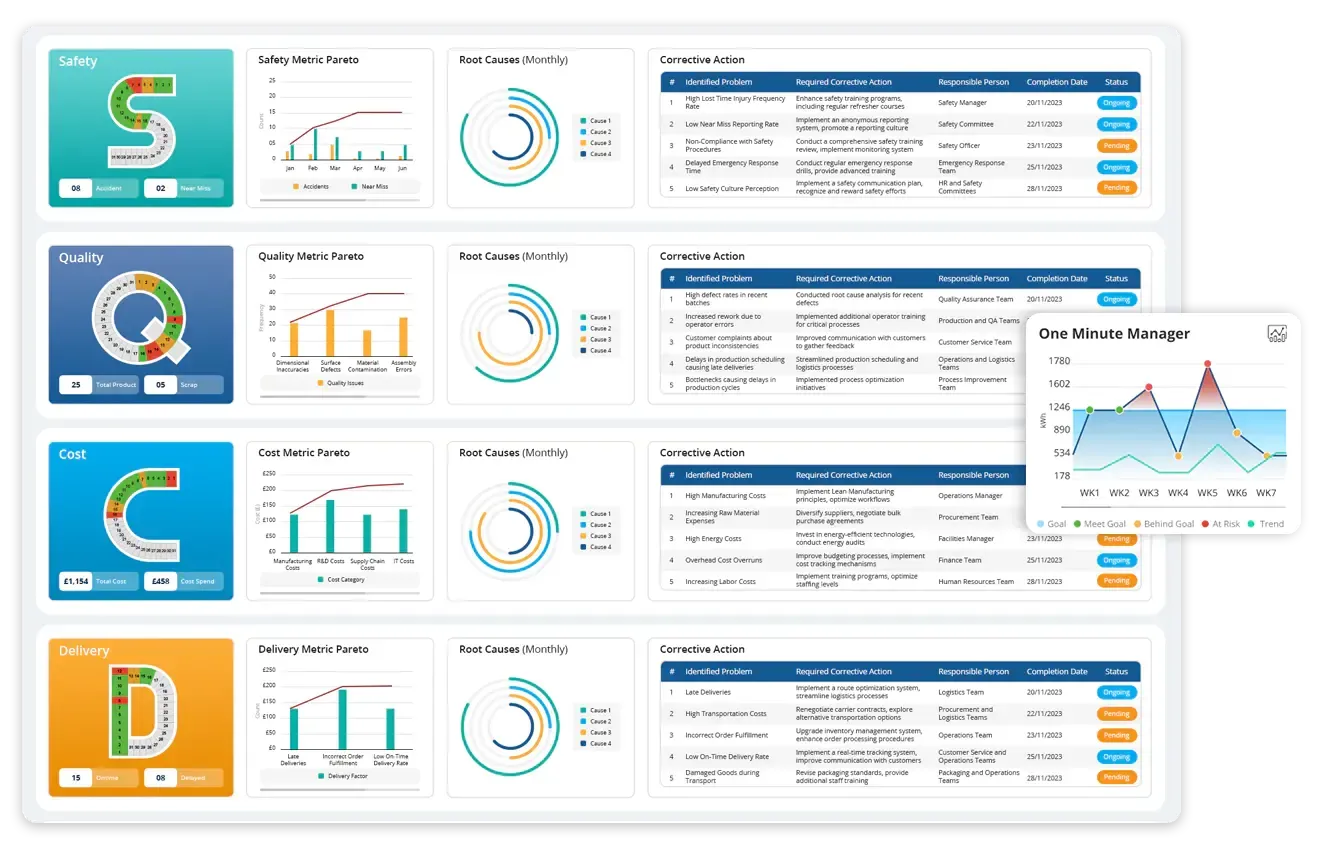

Data Point is more than a KPI dashboard—it’s your all-in-one production tracking tool for lean execution