4. McKinsey 7S framework

The McKinsey 7S model is designed in 1970s to analyse the alignment of seven internal ‘S’ elements —

- Hard elements-Strategy, Structure, Systems

- Soft elements- Shared Values, Style, Staff, and Skills.

The framework shows that all these elements must be in sync for an organisation to function effectively. By assessing gaps in alignment across these components, leadership can identify cultural, structural, or skill-related weaknesses that impede performance or change initiatives.

Key features

- Enables a comprehensive internal diagnostic

- Ideal for transformation, reorganisation, and leadership transitions

- Helps align operations, strategy and execution

- Visual representation supports workshops and boardroom discussions

5. Nadler-Tushman Congruence model

The Nadler-Tushman Congruence Model is a diagnostic tool to uncover why an organisation may be underperforming. It focuses on the congruence or balance between four core components: Work, People, Structure, and Culture. Gaps or misalignments between these elements often lead to inefficiencies, low productivity, or strategic failure.

This model evaluates both inputs (such as resources, leadership, and market conditions) and outputs (like employee behavior and business results) to identify problem areas and guide corrective action.

Key features

- Highlights interdependencies within an organisation

- Diagnoses breakdowns in workflow, behavior, or communication

- Supports strategic alignment efforts

- Useful in leadership development and enterprise restructuring

6. PEST / PESTLE analysis

PEST (Political, Economic, Social, Technological) and PESTLE (adds Legal and Environmental) analysis, mainly identifies external macro-environmental factors that affect business performance. By assessing these factors, businesses can forecast threats and opportunities that may create strategic gaps in the future. It is commonly used during market entry, long-term planning, and regulatory reviews.

Key features

- Helps anticipate future performance risks

- Complements SWOT and benchmarking

- Excellent for strategic foresight in uncertain environments

- Encourages policy, legal, and sustainability awareness

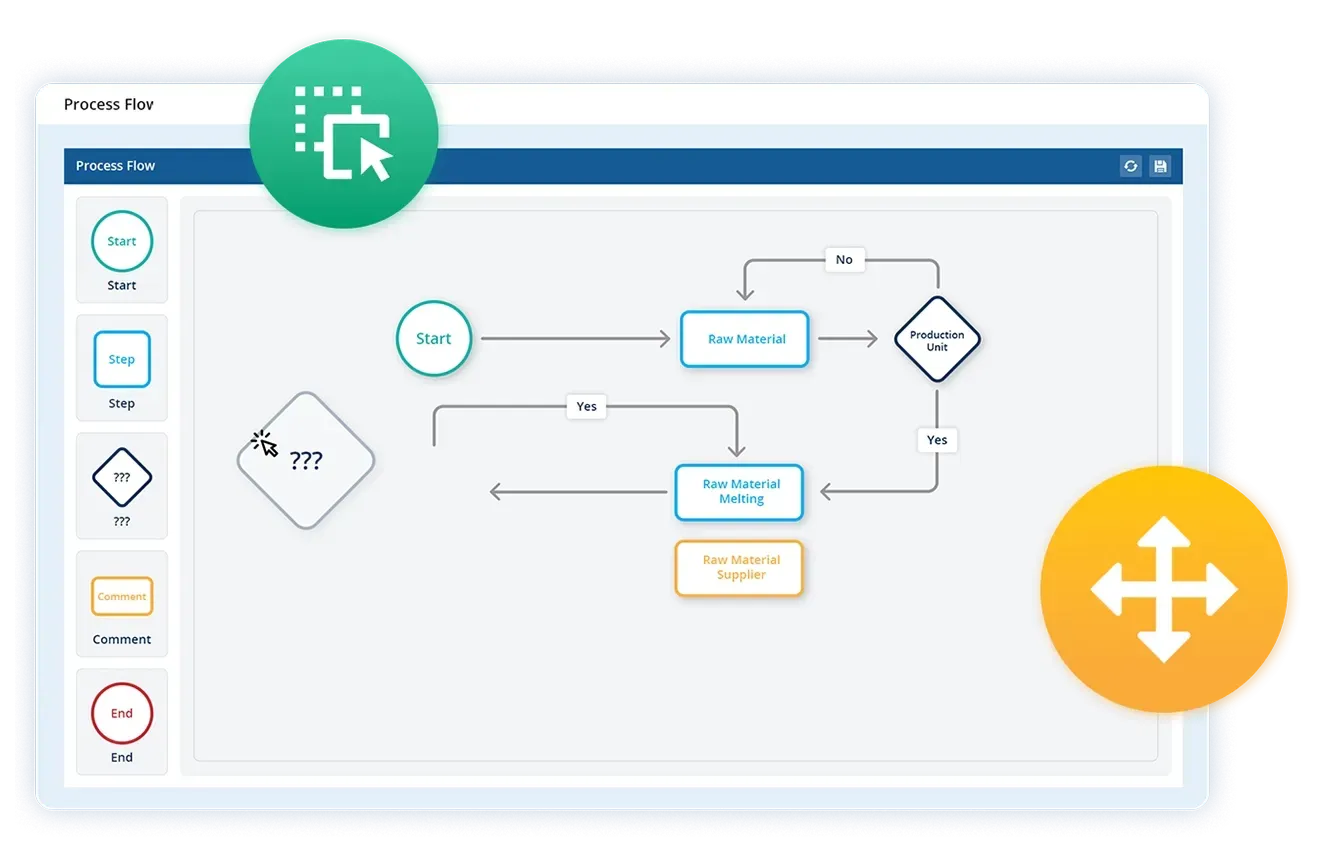

7. Process flowcharts

Flowcharts provide a visual breakdown of tasks, decisions, and workflows, making inefficiencies easy to identify. This tool is particularly effective in manufacturing and service operations, where standardised procedures are essential. By mapping the current and desired workflows, organisations can spot redundancies, bottlenecks, or missing steps contributing to performance gaps.

Key features

- Clarifies process structure and sequence

- Makes process breakdowns visually apparent

- Supports SOP creation and lean six sigma

- Useful in training and onboarding

8. Benchmarking

Benchmarking is the process of comparing your organisation’s performance with industry leaders or direct competitors. It helps you identify where your business falls short and what best practices can be adopted to close those gaps. Benchmarking can be internal (between departments), competitive, or functional (comparing to best-in-class companies across industries).

Key features

- Highlights quantitative and qualitative performance gaps

- Encourages adoption of proven practices

- Tracks KPIs over time or against external sources

- Drives data-informed strategy improvement

9. Burke-Litwin model

The Burke-Litwin Causal Model is a strategic change management framework that explains how different elements within an organisation influence one another and drive overall performance. It identifies the cause-and-effect relationships between internal and external factors—such as leadership, culture, systems, and structure—helping organisations diagnose performance gaps and assess readiness for change.

Key features

- 12 interrelated organisational variables

- Highlights root causes of performance issues

- Differentiates transformational vs. transactional change

- Aligns strategy with operations and employee behavior

- Supports data-driven gap analysis and change planning

Closing the gaps with Data Point software

Gap analysis is a powerful tool for identifying and addressing performance shortfalls within an organisation. By following a structured process and using tools like SWOT analysis, flowcharts, strategy maps, and models such as Burke-Litwin and Nadler-Tushman, businesses can uncover root causes, align strategies, and drive meaningful change.

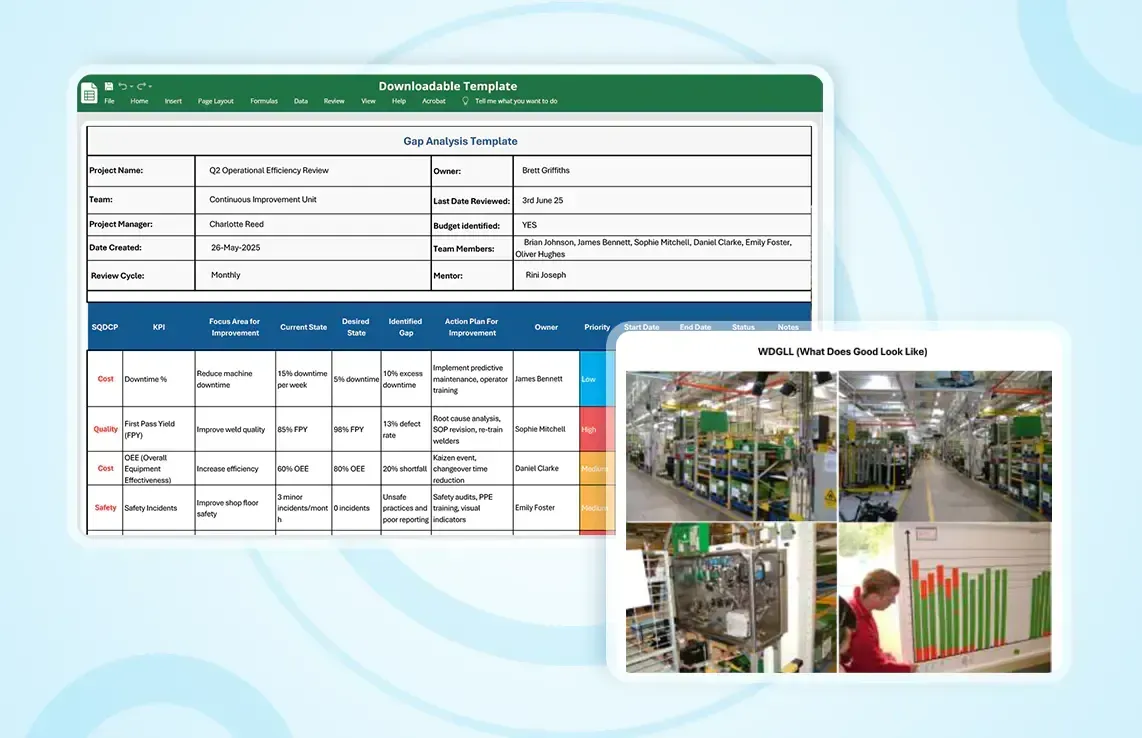

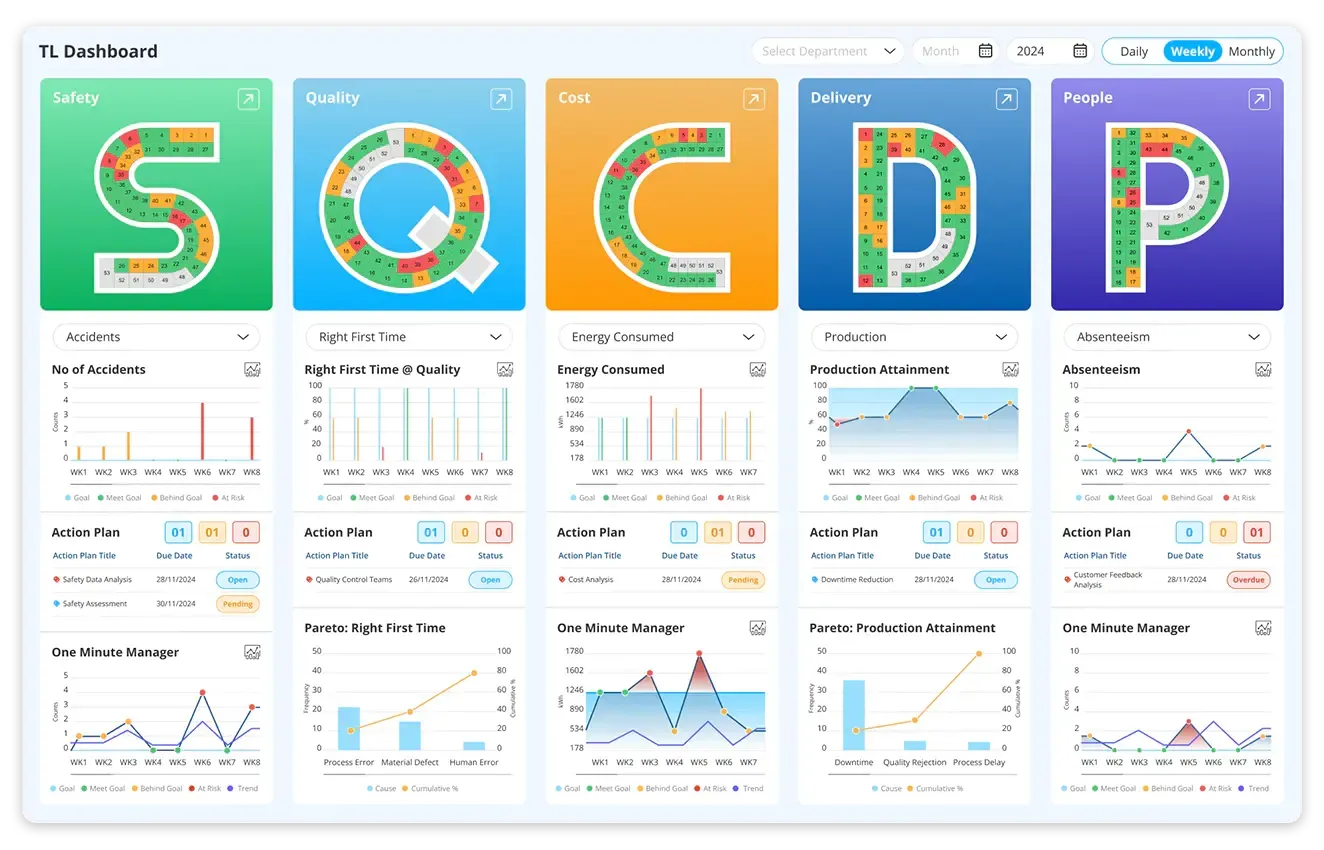

Whether you are optimising workflows or planning transformation, combining gap analysis techniques with the LTS Data Point Balanced Scorecard delivers the clarity, focus, and performance tracking essential for continuous improvement and sustainable growth.

Data Point strengthens this process by translating strategic objectives into measurable KPIs across financial, operational, customer, and learning perspectives. It helps organisations bridge the gap between current performance and long-term goals by enabling real-time tracking, team alignment, and data-driven decision-making. With its visual dashboards and integrated reporting tools, Data Point ensures that the insights uncovered during gap analysis are actively monitored, implemented, and improved upon.

Pinpoint gaps, align your strategy with Data Point Balanced Scorecard